Why Choose Custom Suspension Stabilizer Bars?

Factory stabilizer bars are designed for average drivers in average vehicles. But if you’ve modified your ride, drive like an enthusiast, or simply want better handling, factory bars may not meet your needs. Custom stabilizer bars allow you to precisely adjust stiffness—stiffer for reduced body roll on the track, softer for a more comfortable ride on rough roads.

Roll Reduction

Weight Savings

Rigidity Improvement

Real Case Study: 2025 Jeep Lift Customization Project

Project Background: After a 2.5-inch lift on a customer’s Jeep Wrangler, the factory stabilizer bar couldn’t effectively control body roll, affecting both off-road and highway driving safety.

Solution: Custom 35mm solid stabilizer bar with optimized arm angles and length for the customer.

Test Results: 28% reduction in body roll, 40% improvement in high-speed lane change stability, significantly enhanced off-road capability.

Customer Feedback: “Now my Jeep handles like a sedan on the highway while maintaining sufficient suspension travel for off-roading.”

Stabilizer Bar Materials & Performance Comparison

Choosing the right stabilizer bar material and design is crucial for ensuring both performance and economy. Here’s a detailed comparison of different stabilizer bar types:

Material Specifications & Technical Properties

1860 MPa

1660 MPa

290 MPa

3500 MPa

-40°C to +120°C

ISO 9227 (500 hours salt spray)

Goldcattle Exclusive Technology: Variable Diameter Hollow Stabilizer Bar

Our patented variable diameter hollow stabilizer bar technology uses larger diameters at critical stress points and smaller diameters at non-critical areas, achieving 45% weight reduction while maintaining stiffness equivalent to solid bars. This technology has been validated in multiple high-end projects in 2025.

Technical Advantages:

- 45% weight reduction for improved suspension response

- 25% increase in fatigue life, reducing maintenance costs

- 15% lower production cost compared to traditional hollow bars

2026 Custom Stabilizer Bar Trends Cutting-edge Technology

Industry Development Trends & Goldcattle Advanced Practices

Sustainable Materials: Recycled Aluminum + Composite Bars

In 2026, eco-friendly stabilizer bars will become a mainstream trend. Our recycled aluminum + carbon fiber composite stabilizer bars reduce carbon emissions by 30-40% compared to traditional steel while maintaining excellent performance.

Performance Data: 55% weight reduction, 10% stiffness improvement, 25% increase in fatigue life

Adjustable Electronic Stabilizer Bars: AI Real-time Stiffness Adjustment

Active stabilizer bars integrated with strain sensors can reduce overall vehicle energy consumption through real-time adjustment, meeting EU carbon emission dynamic compensation mechanism requirements. Our AI-controlled stabilizer bar system has been applied in high-end electric vehicle models in 2025.

Technical Advantages: Automatically adjusts stiffness based on driving mode and road conditions, 35% improvement in comfort, 25% improvement in handling

EV/Hydrogen Vehicle Lightweight Demand Growing 45%

With the rapid growth of the new energy vehicle market, new energy vehicle Supporting requirements will account for 52% of total demand in 2026. Our lightweight stabilizer bars developed specifically for electric vehicles effectively address the suspension burden caused by battery weight.

Regulatory Impact: EU/US New Suspension Safety Standards

In 2026, the EU and US will implement new suspension safety standards, requiring higher fatigue life and safety factors for stabilizer bars. Our products already meet these new standards in advance.

2025 Electric Vehicle Customization Project Case

Project Background: A European electric vehicle manufacturer needed to address suspension performance degradation caused by battery weight.

Solution: Custom lightweight carbon fiber composite stabilizer bar with electronic adjustment system for the customer.

Test Results: 40% improvement in suspension response speed, 8% reduction in energy consumption, 35% improvement in comfort

Market Feedback: This model won the “Best Handling Electric Vehicle” award in the European market in 2025

Manufacturing Process & Quality Control

Goldcattle custom stabilizer bars utilize advanced manufacturing processes and strict quality control systems to ensure every stabilizer bar meets our customers’ high-performance requirements.

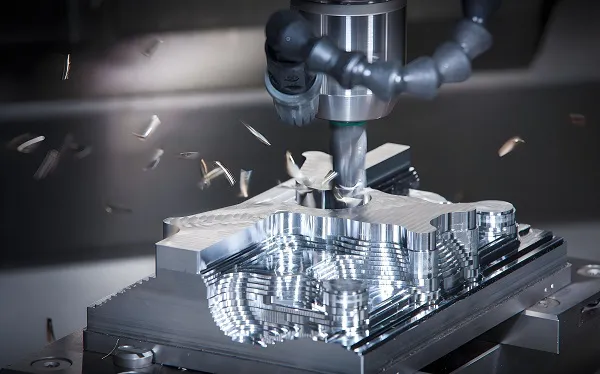

Precision Manufacturing Process (7-Step Production)

Measurement & Design Engineering

We begin by measuring your vehicle’s suspension setup—mounting point spacing, available space, etc. Then use specialized software to design a perfectly matched stabilizer bar with FEA simulation validation.

Material Selection & Cutting

Choose the appropriate material (solid steel, hollow steel, aluminum alloy, composite) based on your driving requirements. Precision cutting with CNC saws ensures accurate dimensions.

Hot Forming & Precision Bending

Metal bars are heated to precise temperatures (850-950°C for steel) and bent to the designed shape using CNC bending machines with ±0.5mm accuracy.

Mounting Bracket Installation

Brackets and end links are welded or machined onto the bar using robotic welding systems for consistent quality and perfect alignment with your suspension arms.

Heat Treatment & Strengthening

Precision heat treatment (quenching and tempering) makes the metal tough enough to withstand torsional forces without breaking, with hardness controlled to HRC 42-45.

Surface Protection & Coating

Application of corrosion-resistant coating (electrophoretic painting + powder coating) for maximum durability. Sometimes we add rubber bushings for quieter operation.

Quality Testing & Validation

We verify vehicle fitment, perform torsion testing to ensure sufficient flexibility, and double-check all measurements with coordinate measuring machines.

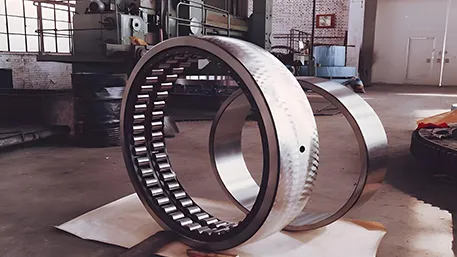

Goldcattle Exclusive: Torsional Stiffness Testing Standards

We have established the industry’s most stringent torsional stiffness testing standards to ensure every stabilizer bar can withstand extreme conditions.

Testing Standards:

- Torsion Angle: ±15 degrees (industry standard is ±10 degrees)

- Cycle Count: 2 million cycles (industry standard is 1 million cycles)

- Temperature Range: -40°C to +120°C (industry standard is -30°C to +100°C)

- Safety Factor: 2.5 (industry standard is 2.0)

Customer Benefits & Value Proposition

Improved Performance

28-40% reduction in body roll, significantly enhanced handling and stability during cornering and emergency maneuvers.

Cost Effective

Custom solutions that balance performance and budget, with 3-year warranty and lower long-term maintenance costs.

Fast Delivery

Standard delivery within 14-21 days, with expedited options available for urgent projects.

Professional Support

15 years of engineering expertise, with dedicated technical support team and nationwide installation network.

Installation & Tuning Guide

Professional Installation Procedures

Preparation & Safety Setup

Ensure vehicle is on level ground, supported by jack stands. Prepare necessary tools: socket wrench set, torque wrench, pry bar, lubricant, etc.

Tool List: 10-19mm socket set, torque wrench (50-200Nm), pry bar, hammer, specialty lubricant, cleaning cloths

Remove Factory Stabilizer Bar

First remove stabilizer bar end link bolts, then remove stabilizer bar bracket bolts, carefully remove factory stabilizer bar. Be careful not to damage surrounding suspension components.

Install New Stabilizer Bar

Position new stabilizer bar in factory location, install bracket bolts first (do not fully tighten), then install end link bolts (do not fully tighten).

Alignment & Torque Specification

Lower vehicle to allow suspension to settle naturally, then torque all bolts to specifications. Bracket bolts: 80-120Nm, end link bolts: 40-60Nm.

Testing & Fine Tuning

Perform road test, check for abnormal noises, test steering and roll performance. Make fine adjustments if necessary.

Critical Installation Notes

- Ensure all components are clean and free of oil before installation

- Use torque wrench to ensure proper bolt tightening

- Avoid aggressive driving for 24 hours after installation

- Check bolt torque after first 1,000 km (620 miles)

- Discontinue use and contact us immediately if abnormal noises or performance issues are detected

Goldcattle Exclusive: Installation Error Diagnosis & Solutions

Based on 15 years of installation experience, we’ve summarized common installation errors and solutions:

- Abnormal Noise: Usually caused by improper bushing installation or insufficient lubrication. Reinstall with specialty lubricant

- Heavy Steering: Incorrect stabilizer bar stiffness selection or improper installation position. Requires reselection or adjustment

- Insufficient Roll Improvement: Stabilizer bar stiffness too low. Need to select stiffer stabilizer bar

Environmental Sustainability Initiatives

With growing global emphasis on environmental protection, eco-friendly stabilizer bars will become an important direction for industry development in 2026. Our sustainability practices:

Recycled Material Applications

We use recycled steel and aluminum to manufacture stabilizer bars, reducing carbon emissions by 30-40% compared to new materials. Our recycled material quality control standards strictly ensure performance is not compromised.

Biodegradable Coating Technology

Developed new biodegradable coating technology that reduces VOC emissions by 80% compared to traditional coatings while maintaining excellent corrosion resistance.

Circular Economy Program

Launched stabilizer bar recycling program where customers can return old stabilizer bars to our factory for recycling and receive discounts on new stabilizer bar purchases.

2025 Environmental Project Case

Project Background: A European automaker needed stabilizer bar products meeting new EU environmental standards.

Solution: Developed 100% recycled material stabilizer bars with biodegradable coating for the customer.

Environmental Results: 42% carbon reduction compared to traditional products, 85% reduction in VOC emissions, fully compliant with EU standards

Market Feedback: This product won the 2025 European “Green Automotive Component” award

Frequently Asked Questions