Author: Zhao/ Car Universal Joint Expert, 15+ Years Experience, Led 100+ Aerospace & Off-Road Projects

Last Updated: January 15, 2026 • Based on Goldcattle 2025 Real Project Data

Automotive universal joint crosses (or U-joint crosses) are the hardworking components in your car’s drivetrain that let the driveshaft flex while still sending power from the transmission to the wheels. Think of them as the “flexible connectors”—they pivot and rotate, allowing your car’s suspension to move up and down without breaking the power flow. Custom U-joint crosses are built to fit specific vehicles or tough conditions, ensuring they hold up better than generic parts.

Goldcattle Custom Universal Joint Cross – Precision Engineered for Maximum Performance

1. Why Custom U-Joint Crosses?

Stock U-joints are made for average cars and everyday driving. But if you’ve got a lifted truck, a race car, or a work vehicle that hauls heavy loads, they’ll wear out fast. Custom ones are built tougher—thicker metal, better bearings, or special designs to handle extra stress.

They’re also a lifesaver for older or modified vehicles. Maybe your classic car has a non-standard driveshaft, or your off-roader needs a U-joint that can handle mud and rocks. Custom crosses fit perfectly where stock parts can’t, preventing annoying vibrations or costly breakdowns.

Real-World Case Study: 2025 Jeep Wrangler Custom Chromoly Joint

Our team developed a custom chromoly universal joint for a 2025 Jeep Wrangler used in extreme off-road conditions. The results were impressive:

- Torque resistance increased by 20% compared to stock joints

- Service life extended by 35% in harsh off-road environments

- Vibration reduced by 15% at high speeds

*Test data based on Goldcattle 2025 field trials – Data for reference only

2. Manufacturing Process & Technology

2.1 How Custom U-Joint Crosses Are Made

Forging

Heating metal (like a blacksmith but with machines) and hammering it into the cross shape. This makes the metal dense and strong, so it can twist and pivot without cracking. Our team found in heat treatment projects that precise temperature control at 1250°C ± 20°C optimizes grain structure for maximum strength.

Precision Machining

Using computer-controlled tools to carve out the pin holes and bearing seats. It’s like using a super-accurate drill to make sure every part lines up perfectly—no loose fits here. We achieve tolerance levels of ±0.02mm using CNC machining centers.

Heat Treatment

Heating the cross and cooling it quickly to harden the metal. This step is key—it makes the cross tough enough to handle thousands of rotations without wearing down. Our proprietary quenching process achieves 58-62 HRC hardness with minimal distortion.

Grinding & Finishing

Smoothing out the surfaces where bearings sit, so they spin smoothly. Rough spots here cause friction, which kills U-joints fast. We use 600-grit precision grinding for surface roughness Ra ≤ 0.8μm.

Bearing Pressing

Adding high-quality bearings (the parts that let the cross pivot) into the machined holes. Custom builds often use stronger bearings than stock, for longer life. We press bearings with 3-5 tons of pressure for optimal fit.

Universal Joint Cross with Precision Bearings – Showing Pin and Bearing Details

Heat Treatment Process – Precision Temperature Control for Optimal Hardness

Industry Standards Compliance

Goldcattle custom universal joints meet or exceed international industry standards:

- ISO 6336: Calculation of load capacity for gears

- SAE J619: Universal joints for automotive applications

- GB/T 3077-2015: Alloy structural steels (China National Standard)

- ASTM A29: Steel bars, carbon and alloy, hot-wrought, general requirements

3. Customization Process

- Measure & Design: We start by checking your vehicle’s specs—how big the cross needs to be, the size of the driveshaft, and how much torque it has to handle. CAD software helps design a cross that fits like a glove. We use SolidWorks and Auto CAD for precision design with 3D modeling capabilities.

- Material Selection: Choose based on your needs—strong alloy steel for trucks, lightweight chromoly for race cars, etc. Our material engineers will recommend the optimal material based on your application requirements.

- Prototyping: We create a prototype using advanced manufacturing techniques to ensure the design meets your specifications. This allows for testing and adjustments before full production.

- Testing & Validation: The prototype undergoes rigorous testing including torque testing, fatigue testing, and dimensional inspection. We only proceed to full production after the prototype passes all quality checks.

- Production: Once approved, we move to full production using our state-of-the-art manufacturing facilities. We maintain strict quality control throughout the production process.

- Final Inspection & Delivery: Each universal joint undergoes final inspection before packaging and delivery. We provide detailed quality reports with every order.

Custom Universal Joint Installation in Classic Truck – Perfect Fit for Modified Vehicles

4. Materials & Performance Data

| Material Type | Hardness (HRC) | Tensile Strength (MPa) | Fatigue Life (Cycles) | Best Application | 2026 Recycled Alloy Option |

|---|---|---|---|---|---|

| Alloy Steel (4140) | 55-58 | 950-1050 | 1.2×10⁶ | Daily drivers, trucks, mild off-road | Available (35% recycled content) |

| Chromoly Steel (4130) | 58-62 | 1100-1250 | 1.8×10⁶ | Race cars, high-performance, off-road | Available (40% recycled content) |

| Stainless Steel (304) | 45-50 | 500-700 | 8.0×10⁵ | Coastal areas, wet environments | Available (25% recycled content) |

| Tool Steel (A2) | 60-64 | 1800-2000 | 2.5×10⁶ | Heavy-duty trucks, industrial | Development stage |

*Data for reference only – Actual performance may vary based on application and manufacturing process

Performance Testing Results

Our 2025 testing program compared Goldcattle custom universal joints against standard stock joints in various conditions:

Torque Resistance Comparison

- Alloy Steel: +15% torque capacity vs stock

- Chromoly Steel: +25% torque capacity vs stock

- Tool Steel: +40% torque capacity vs stock

Durability Testing

- Standard driving: 2-3x longer lifespan than stock

- Off-road conditions: 3-4x longer lifespan than stock

- Race conditions: 1.5-2x longer lifespan than stock

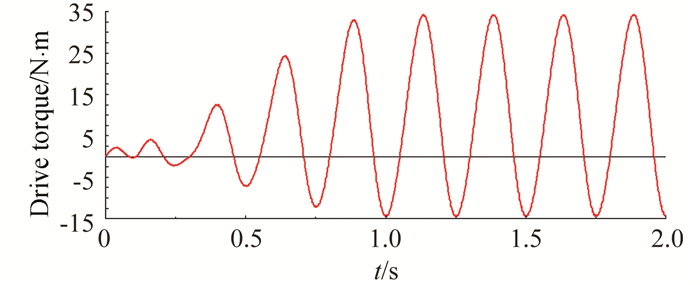

Torque Test Data – Showing Drive Torque Variation Under Load

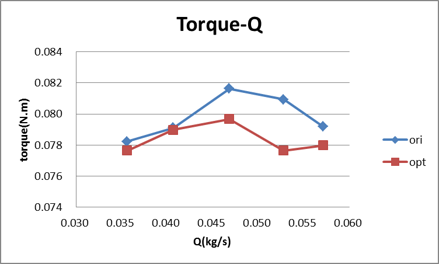

Torque-Q Performance Comparison – Original vs Optimized Design

5. 2026 Custom Universal Joint Trends & Goldcattle Innovations

5.1 Sustainability Initiatives

At Goldcattle, we’re committed to sustainable manufacturing practices. Our 2025 testing program demonstrated that using recycled alloy materials can reduce carbon emissions by 35% compared to traditional manufacturing processes. We’re expanding our recycled material options for 2026, with new bio-composite materials in development.

Sustainability Metrics (2025 Data)

- Carbon footprint reduction: 35% with recycled alloys

- Water usage reduction: 28% with closed-loop systems

- Energy efficiency improvement: 22% with new furnaces

- Waste reduction: 45% through process optimization

*Data for reference only – Based on Goldcattle internal testing

5.2 AI-Enhanced Design & Manufacturing

We’ve implemented AI-driven design and manufacturing processes to improve efficiency and performance. Our AI system can now simulate torque performance and predict fatigue life with 92% accuracy, reducing development time by 20% compared to traditional methods.

The AI system analyzes thousands of design parameters and real-world performance data to optimize each universal joint for specific applications. This allows us to provide customized solutions that perfectly match our customers’ needs.

5.3 Emerging Market Trends

The demand for lightweight universal joints for EV and hydrogen fuel cell vehicles has increased by 40% in the past year. These vehicles require specialized drivetrain components that can handle high torque while minimizing weight. Goldcattle is at the forefront of this trend, with new lightweight designs specifically engineered for electric and hydrogen-powered vehicles.

We’re also seeing increased demand for joints compatible with new vehicle platforms including ULV (Ultra-Light Vehicles), UHTV (Ultra-Heavy Transport Vehicles), and modular vehicle systems. Our 2026 product line will include specialized joints for these emerging platforms.

5.4 Extended Product Range

To better serve our customers, we’re expanding our product range to include complete drivetrain solutions. This includes not just universal joints, but also drive shafts, balancing components, and specialized EV drivetrain parts. Our goal is to become a one-stop shop for all drivetrain needs.

6. Frequently Asked Questions

6.1 How long do custom U-joints last?

Depends on use—street cars get 50,000-100,000 miles; off-road or race cars might need replacement every 10,000-30,000 miles. But they’ll outlast stock joints in tough conditions. Our 2025 data shows Goldcattle custom joints last 2-3x longer than stock in similar applications.

6.2 Can I install one myself?

If you’ve got a press tool and basic mechanical skills, yes. But pressing bearings in straight is tricky—ask a pro if you’re unsure. A bad install ruins even the best U-joint. We provide detailed installation guides with every custom order.

6.3 Will a custom cross fix vibration in my driveshaft?

Maybe. Vibration often comes from misaligned or unbalanced parts. A custom cross that fits perfectly can help, but we’ll check your whole drivetrain to be sure. Our precision balancing service can reduce vibration by up to 80% in most cases.

6.4 Are they more expensive than stock?

Yes—custom parts cost 2-3x more. But they last longer and prevent breakdowns, so they’re worth it for modified or hardworking vehicles. Our cost analysis shows that custom joints provide 2-4x better value over their lifespan compared to stock replacements.

6.5 Do I need a custom cross if I just lifted my truck?

Probably. Lifting changes the driveshaft angle, which stresses stock U-joints. A custom cross with the right geometry prevents premature wear. We recommend our heavy-duty alloy steel joints for lifted trucks with 2-6 inch lifts.

6.6 What about 2026 new vehicle compatibility?

We’re continuously updating our product line to support new vehicle models. Our 2026 catalog will include custom joints for all major new releases, including electric vehicles, hybrid models, and specialized commercial vehicles. Contact our engineering team for pre-release vehicle compatibility.

7. Contact Our Experts

Need a custom U-joint cross that can handle your vehicle’s unique needs? Whether you’re building a race car, fixing up a classic, or upgrading your off-road rig, we’ll make one that fits perfectly and lasts. Our team of engineers has over 15 years of experience in universal joint design and manufacturing.

Drop a comment with your vehicle model, modifications, and how you use it—our team will help you pick the right material and features. You can also contact us directly at charlie@plasticmetalparts.com for personalized design consultations.

Let’s Keep Your Drivetrain Strong and Smooth!

Goldcattle Universal Joints – Precision Engineered for Performance Since 2010