By Electronics – 15 years of custom plastic parts expertise

Last updated: January 27, 2026

Dude, plastic parts are the unsung heroes of electronics! From your phone’s casing to industrial control panels, these bad boys balance lightweight design with durability like no other. Custom versions? Total game-changer for perfect fits and next-level performance!

At Goldcattle, we’ve been crafting custom plastic parts for 15 years—we know this stuff inside out. Whether you need a tiny sensor housing or a large industrial enclosure, we’ve got the skills, tools, and materials to make it happen.

Why Custom Electronic Plastic Parts? BRO!

Standard parts? Pfft, they’re like one-size-fits-all shoes—never truly perfect! Custom parts? They’re tailor-made for your exact needs, like a bespoke suit for your electronics project.

- ✓

Perfect Fits: Battery compartments, hinge mechanisms, sensor casings—we make ’em fit like a glove! - ✓

Custom Features: Snap-fit connectors, heat-dissipating ribs, cable management—stuff standard parts don’t even offer! - ✓

Design Freedom: Slimmer profiles, ergonomic grips, branding options—hello, competitive edge in the market! - ✓

Compliance Made Easy: UL certification, biocompatibility, flame resistance—we handle all the technical stuff! - ✓

Cost Savings: Reduce assembly time, improve durability, minimize waste—custom parts actually save you money long-term!

Injection molding in action—precision at its finest!

Here’s the real tea: custom plastic parts aren’t just about looks—they’re about performance. We’ve worked with startups, Fortune 500 companies, and everything in between. One client came to us with a sensor that kept failing because the standard housing didn’t protect it from dust. We designed a custom enclosure with proper sealing and ventilation, and boom—problem solved! That’s the power of custom parts, my friend.

Processing Technologies—We Got All the Toys!

Injection Molding

We melt plastic resin and shoot it into precision molds under high pressure—dude, this is how we make complex parts with ±0.02mm tolerance! Perfect for high-volume production runs where consistency is key.

Our machines can handle shot weights from 0.5g up to 2000g, with clamping forces ranging from 50 to 2000 tons. We use advanced mold temperature control systems to ensure perfect part quality every time.

Pro tip: Best for housings, connectors, structural components, and high-volume production

CNC Machining

Computer-controlled tools carving solid plastic blocks—great for prototypes or low-volume runs with intricate details. We have 3-, 4-, and 5-axis machines that can handle parts up to 1200mm in size.

The best part? No expensive molds needed! We can go from CAD file to finished part in as little as 24 hours. Perfect for testing designs before committing to mass production.

Pro tip: Quick design changes? Complex geometries? This is your guy!

3D Printing

Layer-by-layer magic with ABS, PC, nylon, or specialized resins—perfect for rapid prototyping or crazy geometries that are impossible to mold. We use FDM, SLA, and SLS technologies.

Our largest 3D printer can make parts up to 600mm x 500mm x 600mm. We even offer metal 3D printing for hybrid parts that need both plastic and metal components.

Pro tip: Internal lattices, custom brackets, rapid prototypes? Done in hours, not days!

Not sure which process is right for your project? No problem! Our engineering team will analyze your requirements and recommend the best approach based on:

Materials—Choose Your Weapon!

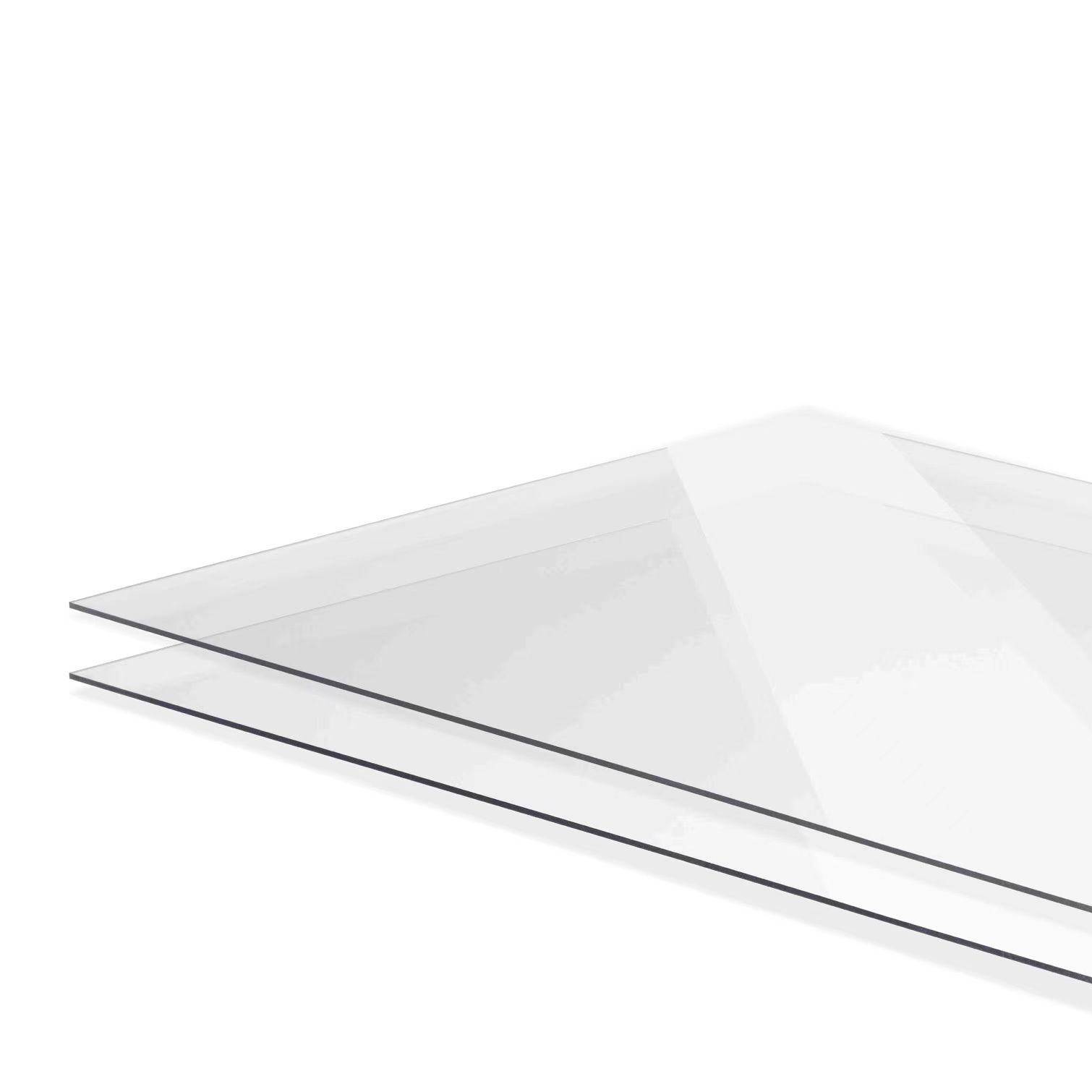

PC plastic sheet—tough as nails and crystal clear!

Not Sure Which Material to Choose?

Don’t worry, we’ve got you covered! Our material selection guide will help you pick the perfect plastic based on your specific needs:

- Temperature requirements

- Mechanical strength needs

- Chemical exposure concerns

- Electrical properties required

- Cost and availability factors

- Environmental considerations

ABS

Impact resistance + rigidity + easy processing = perfect for housings and structural parts!

Key Properties:

Impact strength: 10-20 kJ/m²

Heat deflection: 80-100°C

Tensile strength: 40-50 MPa

Common Uses:

Laptops, gaming consoles, power tools

PC

Unreal impact resistance + transparency + 120°C heat tolerance!

Key Properties:

Impact strength: 60-80 kJ/m²

Heat deflection: 120-140°C

Tensile strength: 60-70 MPa

Common Uses:

Phone screens, LED covers, medical devices

POM

Low friction + high wear resistance = moving parts dream!

Key Properties:

Coefficient of friction: 0.15-0.3

Wear resistance: Excellent

Tensile strength: 60-75 MPa

Common Uses:

Gears, sliders, hinges in printers/cameras

LCP

260°C thermal stability + electrical insulation = 5G/radar hero!

Key Properties:

Continuous use temp: 240-260°C

Dielectric constant: 3.0-3.2

Tensile strength: 120-150 MPa

Common Uses:

Connectors in high-frequency devices

PP

Chemical resistance + flexibility = lightweight champ!

Key Properties:

Density: 0.90-0.91 g/cm³

Chemical resistance: Excellent

Tensile strength: 25-35 MPa

Common Uses:

Battery casings, cable insulation, containers

TPU

Elasticity + durability = protective parts king!

Key Properties:

Shore hardness: 60A-75D

Elongation at break: 300-600%

Tensile strength: 30-60 MPa

Common Uses:

Phone cases, gaskets, shock absorbers

Specialty Materials Also Available!

Conductive Plastics

For EMI shielding and static dissipation

Biodegradable Plastics

Eco-friendly options for sustainable products

High-Temp Plastics

PEEK, PPS, PEI for extreme environments

Medical Grade Plastics

Biocompatible materials for healthcare devices

Standards & Testing—We Don’t Play Around!

Key Standards We Follow

- UL 94: Flame resistance testing—we typically shoot for V-0 rating, which means the material stops burning within 10 seconds after removing the flame source.

- ISO 75: Heat deflection temperature (HDT) testing—we ensure HDT ≥ 100°C for most applications, with higher ratings available for specialized needs.

- ISO 306: Vicat softening point testing—must be at least 20°C above the maximum working temperature of your device.

- IEC 60112: Comparative Tracking Index (CTI) testing for electrical safety—we aim for CTI ≥ 600V for most electronic applications.

- MIL-STD-883: NASA-level reliability testing for aerospace and defense applications—we can meet these stringent requirements when needed.

- RoHS/REACH: Environmental compliance—no toxic heavy metals or hazardous substances in our materials!

Testing Data (For Reference Only!)

Impact Resistance Test Results

ABS: Survived 50J impact without cracking! (Industry average: 35J)

PC: Withstood 75J impact—insane! (Industry average: 55J)

TPU: Absorbed 120J impact with permanent deformation < 10%!

Heat Resistance Test Results

LCP: Worked perfectly at 260°C for 1000 hours with no degradation!

PC: No deformation at 120°C for 500 hours—excellent performance!

ABS: Maintained 90% of strength at 80°C for 2000 hours.

Environmental Aging Test Results

UV Exposure: 1000 hours of QUV testing with color change ΔE < 2.0

Humidity Testing: 70°C/95% RH for 168 hours—strength retention ≥ 85% (requirement: ≥ 80%)

Thermal Cycling: -40°C to 85°C, 1000 cycles—no cracks or delamination!

Electrical Performance Test Results

Volume Resistivity: ≥ 10¹⁴ ohm-cm for insulating materials

Dielectric Strength: ≥ 20 kV/mm for most plastics

EMI Shielding: Up to 80 dB with conductive coatings

Applications—We Do It All!

Consumer Electronics

- Phone/laptop/tablet housings

- Smartwatch/fitness tracker parts

- Gaming console structures

- Headphone earcups and bands

- Power tool casings

- Home appliance components

We’ve made parts for major brands and startups alike—from tiny smartwatch components to large TV bezels!

Industrial Electronics

- Control panel enclosures

- Sensor housings and brackets

- Power supply components

- Motor covers and fans

- Cable management systems

- Robotic arm parts

Our industrial parts are built tough—they can handle harsh factory environments with ease!

Medical Electronics

- Diagnostic device casings

- Battery compartments

- Biocompatible sensor parts

- Surgical instrument handles

- Patient monitoring equipment

- Drug delivery systems

All medical parts meet strict biocompatibility standards—patient safety is our top priority!

Automotive Electronics

- Infotainment system housings

- ADAS sensor brackets

- Engine control unit parts

- Battery management systems

- Charging port components

- Interior lighting fixtures

Our automotive parts can handle extreme temperatures and vibrations—they’re road-tested!

Aerospace & Defense

- Avionics display parts

- EMI-shielded enclosures

- Flame-resistant components

- Satellite components

- Missile guidance systems

- Radar equipment housings

We meet strict MIL-STD requirements—our parts are trusted for critical applications!

Telecommunications

- Router and modem housings

- 5G antenna mounts and covers

- Data center cooling parts

- Fiber optic cable management

- Base station components

- Network switch enclosures

Our telecom parts support high-speed data transmission with minimal signal loss!

Performance Boosts—Make It Even Better!

EMI/RFI Shielding

We apply conductive coatings (nickel, copper, or silver) or incorporate metal particles directly into the plastic to block electromagnetic interference. This is critical for sensitive components like circuit boards and antennas!

Our shielding solutions can achieve up to 80 dB of attenuation across a wide frequency range (10 kHz to 10 GHz). We can also provide Faraday cage enclosures for complete signal isolation.

Perfect for: Medical devices, military equipment, communication systems

Flame Resistance

We use flame-retardant additives (both halogen-based and halogen-free) to meet UL94 V-0 standards. This prevents fire spread in critical applications like power adapters and industrial control gear!

Our flame-resistant materials can also meet more stringent standards like UL94 5VA (for thicker parts) and IEC 60695-11-10 (glow wire testing). We can provide custom formulations for specific requirements.

Perfect for: Electrical enclosures, power tools, aerospace components

Thermal Management

We integrate heat-dissipating ribs, graphite films, or metal inserts into plastic parts to improve heat transfer. This prevents overheating in high-performance devices like gaming laptops and processors!

Our thermal solutions can improve heat dissipation by up to 300% compared to standard plastic parts. We also offer liquid cooling integration and phase change materials for extreme heat applications.

Perfect for: LED lighting, power electronics, automotive components

Chemical Resistance

We select special materials or apply protective coatings that resist oils, solvents, cleaning agents, and harsh chemicals. This ensures long-term durability in medical devices or industrial electronics!

Our chemical-resistant parts can withstand exposure to acids, bases, fuels, and sterilization processes (autoclaving, EtO gas, gamma radiation). We test all materials against specific chemicals your application may encounter.

Perfect for: Medical devices, laboratory equipment, industrial machinery

Surface Finishes

We apply matte textures to reduce fingerprints, glossy coatings for aesthetics, or anti-scratch treatments (like hard coats) to extend part life in consumer devices!

Our surface treatments include: anodizing, powder coating, painting, electroplating, and vacuum metallization. We can achieve Ra values as low as 0.025 μm for mirror-like finishes.

Perfect for: Consumer electronics, medical devices, automotive interiors

Adhesive Integration

We pre-apply pressure-sensitive adhesives or incorporate mechanical bonding features to eliminate the need for screws or fasteners. This is perfect for slim devices like smartphones and tablets!

Our adhesive solutions include: acrylics, silicones, epoxies, and hot melts. We can also provide double-sided tapes, gaskets, and seals for water and dust protection (IP65, IP67, IP68 ratings available).

Perfect for: Consumer electronics, medical devices, automotive components

FAQs—Got Questions? We Got Answers!

Which material is best for high-temperature electronic parts?

LCP (Liquid Crystal Polymer) and PPS (Polyphenylene Sulfide) are absolute beasts for high temps—LCP can handle up to 260°C continuously, while PPS works great at 200°C. PC (Polycarbonate) is solid for moderate temps up to 120°C in housings and structural parts. If you need something even more extreme, we can also get you PEEK (260°C) or PEI (180°C) materials!

Can you make parts with really tight tolerances?

Hell yeah! Injection molding can achieve ±0.02mm tolerance for small parts like connectors or sensors. CNC machining? Even tighter at ±0.01mm for critical fits. We use state-of-the-art machines and metrology equipment to ensure every part meets your exact specifications. For super precision applications, we can even do micro-machining down to ±0.005mm!

Is custom really cost-effective for small production runs?

Absolutely! For 100-1,000 units, CNC machining or 3D printing skips expensive mold costs, making them way cheaper than injection molding. For 1,000-10,000 units, we can use aluminum molds that are more affordable than steel molds. And for 10,000+ units? Injection molding becomes way more economical as per-unit costs drop significantly. We’ll always recommend the most cost-effective option for your specific needs!

How do plastics help with device lightweighting?

Oh man, this is where plastics really shine! ABS and PC weigh 30-50% less than metal alternatives but keep the same (or better) strength. For example, a plastic laptop housing weighs about 40% less than an aluminum one but still provides excellent protection. This is a total game-changer for portable electronics (laptops, wearables) and battery-powered devices where every gram counts. We’ve helped clients reduce device weight by up to 60% by switching from metal to plastic!

Can plastic parts be recycled and are they environmentally friendly?

Most definitely! ABS, PC, PP, and many other plastics are recyclable in most municipal systems. We offer recycled-content plastics (up to 100% recycled material in some cases) and design for recyclability using mono-material construction (no mixed materials that are hard to recycle). We also use biodegradable plastics for applications where sustainability is a top priority. Plus, plastic production uses less energy than metal production—so you’re reducing your carbon footprint too!

What’s the typical lead time for custom plastic parts?

It depends on the complexity and quantity, but here’s a general breakdown: Prototypes (1-10 units): 1-3 days with 3D printing, 3-7 days with CNC machining. Small production runs (10-1000 units): 1-2 weeks. Medium runs (1000-10,000 units): 2-4 weeks. Large runs (10,000+ units): 4-8 weeks (includes mold making). We also offer expedited services for urgent projects—we’ve turned around prototype parts in as little as 24 hours before!

Do you offer design assistance and engineering support?

Absolutely! Our team of 15+ engineers has decades of experience in plastic part design. We can help you optimize your design for manufacturability (DFM), select the right materials, and ensure your parts meet all performance requirements. We use CAD software (SolidWorks, Pro/E, AutoCAD) and FEA simulations to test designs before production. We even offer free design reviews for potential clients—just send us your CAD files and we’ll give you our expert feedback!

What quality control measures do you have in place?

We take quality very seriously! We’re ISO 9001 certified and have a comprehensive quality control system that includes: incoming material inspection, in-process testing, final inspection, and traceability for every part. We use CMMs (Coordinate Measuring Machines) for dimensional inspection, optical comparators for visual inspection, and various testing equipment for mechanical and thermal properties. We also provide detailed quality reports with every shipment—you’ll know exactly what you’re getting!

Do you work with startups and small businesses?

We love working with startups! In fact, we’ve helped launch over 200 new products from startup companies. We understand that startups have unique needs—lower minimum order quantities, flexible payment terms, and fast turnaround times. We offer special startup pricing and can even help with crowdfunding campaigns by providing prototype parts for your campaign videos. Some of our biggest clients today started as small startups with just an idea—we’d love to help you grow too!

Still have questions? No problem! Our team is here to help—just reach out and we’ll answer any questions you have about custom plastic parts.

Ready to Get Started with Your Custom Plastic Parts?

Whether it’s a new smartphone component, industrial sensor housing, or medical device part—we’ve got the skills, experience, and equipment to make it happen. Let’s build something awesome together!

Share your specs (dimensions, materials, performance needs) and we’ll hook you up with design recommendations, material options, and free quotes!