In the wave of the manufacturing industry’s transformation towards high precision, lightweight, and personalization, the customized 3D – printed metal parts service, with its unique technical advantages, has become a key solution to traditional manufacturing challenges. From high – temperature alloy components in aerospace to titanium – alloy implants in the medical field, this technology breaks through material limitations and structural constraints, enabling the efficient manufacturing of complex geometric shapes. This article will deeply analyze the technical strength and market value of the customized 3D – printed metal parts service by focusing on core aspects such as technical principles, material characteristics, application scenarios, and customization processes, combined with actual data and cases.

I. Analysis of the Core Technologies of 3D – printed Metal Parts

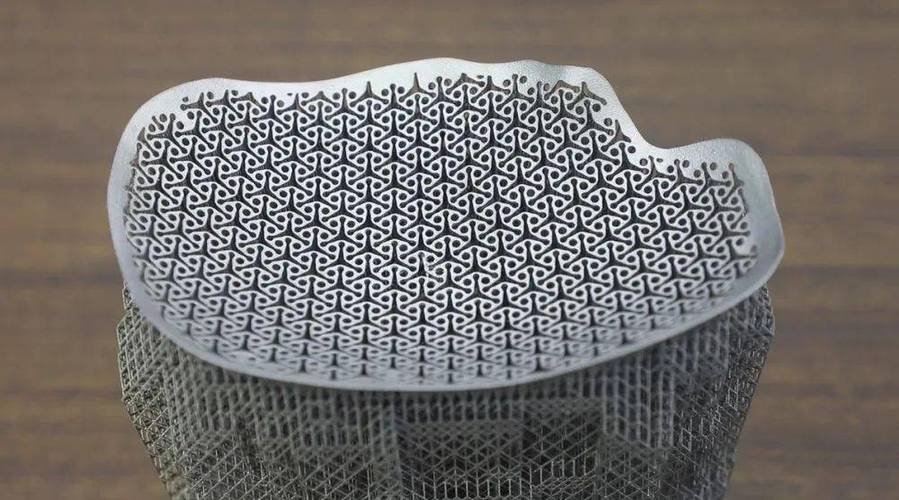

Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Energy Deposition (DED) are the three core technologies of metal 3D printing. The SLM technology uses a high – power laser (100 – 500W) to melt metal powder layer by layer, with a forming accuracy of ±0.05mm, suitable for manufacturing precision parts. The EBM technology melts metals through an electron beam in a vacuum environment, with a printing speed 3 – 5 times faster than SLM, and is suitable for processing high – melting – point materials such as titanium alloy. The DED technology realizes the additive manufacturing of large – scale metal components through synchronous powder or wire feeding and high – energy beam melting, with a material utilization rate of over 90%.

II. Performance and Application of Metal 3D – printing Materials

Metal 3D – printing materials cover various types such as titanium alloy, stainless steel, and aluminum alloy. Due to its high strength and low density, titanium alloy accounts for 45% of applications in the aerospace field. For example, the 3D – printed titanium – alloy bracket of Airbus A350 reduces the weight by 40%. Stainless steel, with its good corrosion resistance and cost – effectiveness, accounts for more than 60% of the medical implant market. Aluminum alloy, with its lightweight characteristics, is widely used in automotive manufacturing. Tesla reduces the weight of components by 30% through 3D – printed aluminum – alloy parts.

III. Application Scenarios of Customized 3D – printed Metal Parts

In the aerospace field, 3D – printed metal parts significantly improve component performance. The copper – alloy combustion chamber printed by SpaceX using the SLM technology has reduced the production cycle from 6 months to 4 weeks. In automotive manufacturing, Porsche reduces the weight of aluminum – alloy brake calipers by 16% and increases the heat – dissipation efficiency by 20% through 3D printing. In mold manufacturing, 3D – printed molds with conformal cooling channels shorten the injection – molding cycle by 30%, significantly improving production efficiency.

IV. Quality Control System for 3D – printed Metal Parts

Metal 3D printing must follow strict quality standards. During the production process, an AI algorithm is used to monitor 15 key parameters such as laser power and scanning speed in real – time, controlling the printing defect rate within 3%. For finished – product inspection, means such as CT scanning and metallographic analysis are used to ensure that there are no pores inside the parts and that the mechanical properties meet the standards. The product density of some enterprises can reach 99.9%.

V. Cost – optimization Paths for 3D – printed Metal Parts

Technological progress has significantly reduced costs. The price of industrial – grade SLM equipment has decreased by 30% compared to five years ago, and the cost of metal powder is expected to drop by 40% by 2030. Taking small – sized metal parts as an example, the unit cost of 3D printing has dropped from 800 yuan to 500 yuan, a decrease of 37.5%. Mass production and the popularization of domestic equipment have continuously improved the cost – performance of customized metal parts.

VI. Policies and Regulations for the Metal 3D – printing Industry

National policies strongly support the development of metal 3D printing. China has included it in the key development technologies of the “14th Five – Year Plan for Intelligent Manufacturing Development”. Local governments have introduced subsidy policies. For example, Xi’an provides a maximum of 5 million yuan in R & D subsidies to metal 3D – printing enterprises. Industry standards are gradually being improved, and 12 national standards related to metal 3D printing have been issued, providing a guarantee for the standardized development of the industry.

VII. Detailed Explanation of the Process for Customized 3D – printed Metal Parts

Demand Communication and Data Confirmation: Have in – depth communication with customers about the part’s purpose and performance requirements, and confirm the 3D model data or assist in completing the design.

Process and Material Selection: Select appropriate processes such as SLM and EBM according to the part’s requirements, and match corresponding materials such as titanium alloy and stainless steel.

Printing and Support Processing: Conduct 3D printing. After completion, remove the support structure and perform preliminary grinding on the part.

Post – processing: Carry out heat treatment to eliminate stress, surface polishing, hot isostatic pressing (HIP), etc., according to requirements to improve the part’s performance.

Quality Inspection and Delivery: Pass 12 inspections such as dimensional measurement and mechanical property testing, and then package and deliver after passing.

VIII. Inventory of Processing Technologies for 3D – printed Metal Parts

Selective Laser Melting (SLM): Suitable for materials such as titanium alloy and stainless steel, it can manufacture complex and precision parts, with a surface roughness Ra of 10 – 20μm.

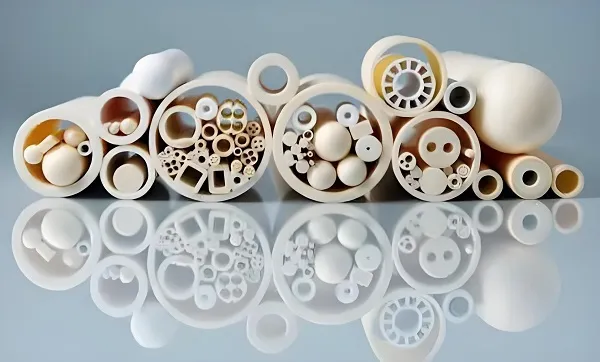

Electron Beam Melting (EBM): Processes high – melting – point materials such as titanium alloy and nickel – based alloy in a vacuum environment, with high printing efficiency, suitable for large – scale structural parts.

Direct Energy Deposition (DED): Supports powder or wire feeding, can be used for part repair and large – component manufacturing, with a deposition rate of up to several kilograms per hour.

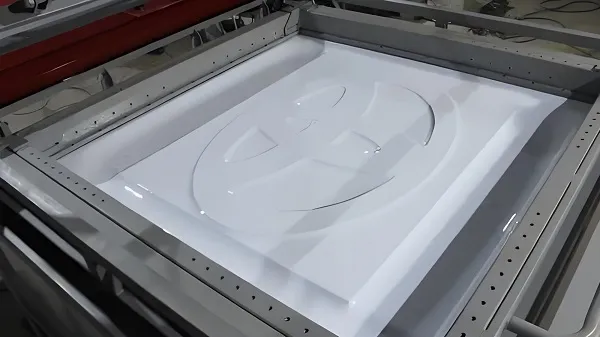

Binder Jetting: Cures metal powder by spraying a binder, suitable for mass production, and requires debinding and sintering treatment later.

IX. Frequently Asked Questions about Customized 3D – printed Metal Parts

Q1: How long does it take to customize metal parts?

A: The production cycle for regular parts is 7 – 15 working days. For complex parts or urgent orders, it can be shortened to 3 – 7 days through negotiation.

Q2: How to ensure the mechanical properties of the parts?

A: Use metal materials certified by international standards, strictly monitor the production process, and test the mechanical properties such as tensile strength and hardness of the finished products.

Q3: Can large – sized metal parts be printed?

A: Through the DED technology, metal components with a maximum size of 2 meters can be printed to meet the customization needs of large – sized parts.

Q4: Which file formats are supported?

A: Common 3D model formats such as STL, STEP, and IGES are supported, and professional design and modeling services can also be provided.

The customized 3D – printed metal parts service is bringing new possibilities to the manufacturing industry. Whether it is high – performance aerospace components or precision mold parts, we can provide professional solutions. If you have customization needs or technical inquiries, please leave a message in the comment area, and we will provide you with one – to – one exclusive services!