Overview of Aerospace Components

Aerospace components are indispensable key parts in the manufacture and maintenance of aircraft, with their quality and performance directly related to the safety, reliability, and lifespan of the aircraft. Aerospace components are numerous in variety, including engine parts, fuselage structural components, avionics components, etc., each requiring precise design and manufacture to meet the high standards and rigorous requirements of the aerospace industry.

1. The Role of CNC in Aerospace

CNC (Computer Numerical Control) technology plays a vital role in the aerospace industry, specifically manifested in the following aspects:

- High-Precision Machining: CNC technology can achieve micron-level machining accuracy, which is crucial for aerospace components because any slight error may affect the performance and safety of the entire aircraft.

- Efficient Production: By automating the machining process, CNC technology significantly boosts production efficiency, reducing manual intervention and machining time, thereby shortening the manufacturing cycle of aircraft.

- Strong Flexibility: Aerospace components are diverse in type and complex in shape. CNC technology can quickly adapt to the machining needs of different components by changing tools and adjusting programs, suitable for small-batch, multi-variety production modes.

- Excellent Consistency: In mass production, component consistency is crucial. CNC technology ensures that the machining parameters of each component are identical, avoiding quality fluctuations due to human factors, thereby ensuring product consistency and stability.

2. CNC Technology for Aerospace Components

CNC technology for aerospace components mainly includes the following aspects:

- CAD/CAM Integration: Draw component drawings using CAD software and import the data into the control system of the CNC machining machine tool, achieving seamless integration of design and manufacture.

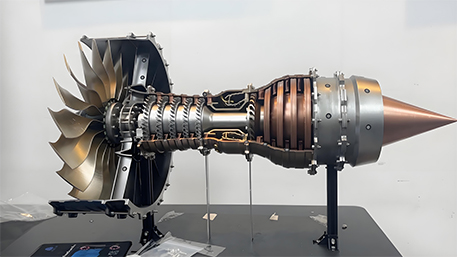

- Multi-Axis Simultaneous Machining: CNC machine tools can perform multi-axis simultaneous machining, suitable for manufacturing complex-shaped aerospace components such as engine blades and turbine disks.

- High-Precision Measurement and Feedback: During the CNC machining process, high-precision sensors are used to monitor the machining status in real-time to ensure machining accuracy and surface quality.

- Automated Control: CNC machine tools employ automated control systems to automate the machining process, reducing manual intervention and improving production efficiency.

3. Advantages of CNC Machining for Aerospace Components

CNC machining for aerospace components offers the following advantages:

- High Precision: CNC technology can machine within micron-level accuracy, ensuring that the size and shape of components fully meet design requirements.

- High Efficiency: CNC machining technology significantly improves production efficiency by automating the machining process, reducing production cycles and costs.

- Flexibility: CNC technology can quickly adapt to the machining needs of different shapes and materials by changing tools and adjusting programs.

- Excellent Consistency: CNC machining technology ensures that the machining parameters of each component are identical, avoiding quality fluctuations due to human factors.

4. Materials for CNC Machining of Aerospace Components

| Material | Characteristics | Applications in Aerospace |

|---|---|---|

| Aluminum Alloy | Lightweight, high strength, good thermal conductivity, and corrosion resistance | Aerospace components, automotive parts, electronic product cases |

| Stainless Steel | Corrosion resistance and high-temperature strength | Kitchenware, medical equipment, chemical containers |

| Titanium Alloy | High strength, low density, excellent corrosion resistance, and high-temperature performance | Aerospace, automotive, medical equipment manufacturing |

| Carbon Steel | High strength and hardness, durability, safety, long shelf life, economical, and environmentally friendly | Automotive parts, building structures, cutting tools |

| Hard Alloy | High hardness, strength, wear resistance, and corrosion resistance | Cutting tools for cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone, and ordinary steel |

5. Standards for Aerospace Components

The standards for aerospace components are very strict, mainly including the following aspects:

- Material Standards: The materials used for aerospace components must comply with relevant international or industry standards, such as ASTM, AMS, etc.

- Design Standards: The design of aerospace components must meet relevant design specifications and standards, such as MIL-STD, NASA standards, etc.

- Manufacturing Standards: The manufacturing process of aerospace components must follow relevant manufacturing process standards and quality control standards, such as AS9100, etc.

- Inspection Standards: Aerospace components must undergo rigorous inspection and testing to ensure their quality and performance meet relevant standards and requirements.

6. Introduction to Aerospace Component Machining Equipment

Aerospace component machining equipment mainly includes the following categories:

- CNC Machining Centers: Featuring high precision, high efficiency, and multi-axis simultaneous machining, suitable for processing complex-shaped aerospace components.

- CNC Lathes: Suitable for processing shaft-type, disk-type, and other rotating components, with high precision, high efficiency, and high automation.

- CNC Grinders: Suitable for processing high-precision, high-surface-quality aerospace components such as engine blades and bearings.

- Laser Cutting Machines: Suitable for processing thin sheet materials, featuring high precision, high efficiency, and non-contact machining.

8. Evaluation of Xiamen Goldcattle Aerospace Components

Xiamen Goldcattle has a high reputation and advantage in customized aerospace component services. Its products are reliable in quality, stable in performance, and comply with relevant standards and requirements. Additionally, Xiamen Goldcattle boasts a professional technical team and advanced production equipment, capable of providing efficient and precise customized services. Customers generally have high evaluations of it, believing that it excels in product quality, delivery time, and service attitude.

FAQ for Customized Aerospace Component Services

Q1: How do I customize aerospace components?

A1: You can contact professional aerospace component customization service providers such as Xiamen Goldcattle, provide component drawings and requirements, and the service provider will design and manufacture according to your needs.

Q2: How long does it take to customize aerospace components?

A2: The time required to customize aerospace components depends on factors such as component complexity, quantity, and production equipment capacity. Generally, the service provider will arrange production as soon as possible after receiving the order and deliver the product within the specified time.

Q3: How is the quality of customized aerospace components guaranteed?

A3: The service provider will strictly follow relevant standards and requirements for design and manufacture, while adopting advanced testing equipment and processes for quality inspection and control to ensure that product quality complies with relevant standards and requirements.

Q4: How is the price of customized aerospace components calculated?

A4: The price of customized aerospace components depends on factors such as component material, quantity, complexity, and production equipment costs. The service provider will provide a quotation based on your specific needs, along with detailed price breakdowns and calculation methods.