Black nylon gasket is a kind of precision parts made of high-quality nylon material, which is widely used in machinery, electronics, automobile, aerospace and other fields, with its high strength, wear-resistant, corrosion-resistant and self-lubricating characteristics, it has become an indispensable sealing and cushioning element in all kinds of equipments and devices.

1.Black nylon gasket production process

Raw material selection and proportioning: select high quality black nylon particles, according to product performance and customer demand for raw material proportioning, to ensure that the gasket has excellent physical and chemical properties.

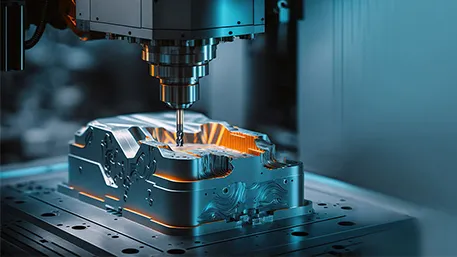

Mold design and manufacture: according to the design drawings of the gasket, precisely design and manufacture the injection mold to ensure that the shape, size and precision of the gasket meets the customer’s requirements.

Injection molding: Feed the well-proportioned nylon granules into the injection molding machine, inject the material into the mold through high temperature and high pressure, and form the basic shape of the gasket after cooling.

Post-processing: The injection molded gaskets are trimmed, deburred and other post-processing to ensure that the surface of the gaskets is smooth and flawless.

Quality Inspection: Strict dimensional measurement, performance test and appearance inspection are carried out on the gaskets to ensure that the quality of the products meets the requirements of customers and industry standards.

Packing and shipping: Pack the qualified gaskets and ship them according to the time and place required by customers.

2.Black nylon shims customization

Size customization: Provide a variety of standard size gaskets for customers to choose, at the same time can be customized according to the specific needs of customers to ensure that the gaskets can be perfectly adapted to the customer’s equipment and devices.

Shape customization: According to customer’s drawings or samples, we can customize the shape to meet the needs of special application scenarios.

Thickness customization: We provide a variety of thicknesses of gaskets for customers to choose from, and at the same time, we can customize the thickness according to the customer’s pressure, temperature and other needs to ensure that the gaskets can meet the customer’s sealing and cushioning requirements.

Material customization: In addition to black nylon, we can also provide other materials (such as stainless steel, copper, etc.) gasket customization services to meet the customer’s special requirements for material performance.

3. Black nylon gasket material introduction

Material: black nylon (PA6, PA66, POM, etc.)

Characteristics:

High strength: black nylon gasket has excellent tensile strength and compression strength, and can withstand greater pressure and load.

Abrasion resistance: nylon material has good abrasion resistance, can maintain stable performance under long-term friction, to extend the service life of the gasket.

Corrosion resistance: black nylon gasket has good corrosion resistance to a variety of chemicals, can be used in harsh environments for a long time without deterioration.

Self-lubricating: nylon material itself has a certain degree of self-lubrication, can reduce friction resistance, improve the operating efficiency of the equipment.

Easy processing: nylon material is easy to injection molding and processing, to meet the requirements of a variety of complex shapes and sizes.

4. Different materials black nylon gasket characteristics

PA6 gasket:

Density: about 1.13g/cm³

Tensile strength: ≥50MPa

Compression strength: ≥70MPa

Friction coefficient: 0.1-0.3

Use temperature range: -40℃ to +80℃

PA66 gasket:

Density: about 1.15g/cm³

Tensile strength: ≥60MPa

Compression strength: ≥90MPa

Friction coefficient: 0.1-0.35

Use temperature range: -40℃ to +100℃

POM gasket:

Density: about 1.42g/cm³

Tensile strength: ≥65MPa

Compression strength: ≥100MPa

Friction coefficient: 0.05-0.15

Temperature range: -40℃ to +110

(Note: The above data is for reference only, the specific value may vary depending on the production process and raw materials.)

Customized Black Nylon Gasket Service FAQ

Q1: Can you provide customized service?

A: Yes, we offer a full range of customized services, including size, shape, thickness and material customization.

Q2: What is the lead time for customized shims?

A: The lead time depends on the complexity and quantity of the customized gaskets, usually within 3-15 working days.

Q3: What materials do you offer for customized gaskets?

A: We provide customized gaskets in black nylon (PA6, PA66, POM, etc.) as well as other materials to meet customers’ different needs.

Q4: How to ensure the quality of customized gaskets?

A: We have a perfect quality management system and advanced production equipment, and carry out strict quality testing on each batch of gaskets to ensure that the product quality meets customer requirements and industry standards.