In the pursuit of personalization and high quality of the modern home furnishing market, custom CNC furniture hardware parts have become an indispensable part of the furniture manufacturing industry due to its high precision, flexible design, fast production efficiency, etc. CNC (Computer Numerical Control) technology controls the machine tool through programming to achieve the complex shapes and high-precision requirements of hardware processing, bringing unlimited possibilities for furniture design. CNC (Computer Numerical Control, computer numerical control) technology through the programming control machine tools, realize the complex shape and high precision requirements of hardware processing for furniture design has brought unlimited possibilities.

1. CNC furniture hardware parts production process

Design stage: According to the customer’s demand or the designer’s idea, use CAD (Computer Aided Design) software to draw the three-dimensional model of the parts, to ensure the accuracy and aesthetics of the design.

Programming: CAD drawings are converted into codes recognizable by the CNC machine tool, i.e. G-code, which is the set of instructions to control the movement of the machine tool.

Raw Material Preparation: Select suitable metal materials, such as stainless steel, aluminum alloy, brass, etc., according to the design requirements, and cut or pre-treat them.

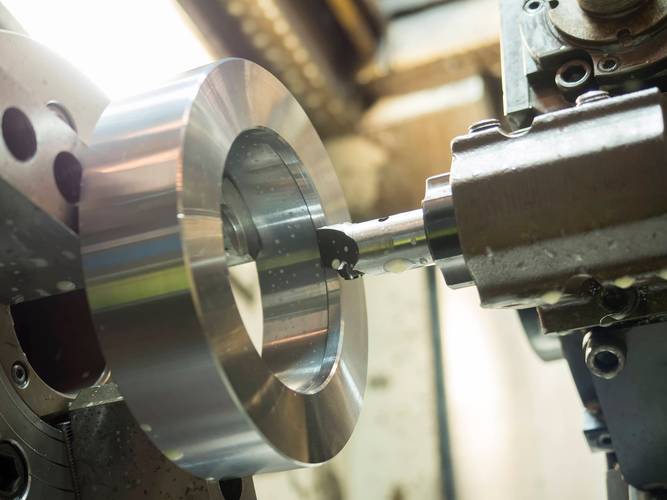

Machining process: CNC machine tools automatically perform machining operations such as cutting, drilling, milling, engraving, etc. in accordance with the preset G-code to achieve precise molding of parts.

Quality Inspection: Through manual inspection and measuring equipment, we ensure that the dimensional accuracy, surface finish, etc. of each part meets the standards.

Surface treatment: Perform surface treatment such as plating, spraying, polishing, etc. as needed to enhance the corrosion resistance and aesthetics of the parts.

Assembling and testing: assemble the finished parts into finished furniture hardware, and conduct functional testing to ensure reliable quality.

2. CNC furniture hardware parts processing steps

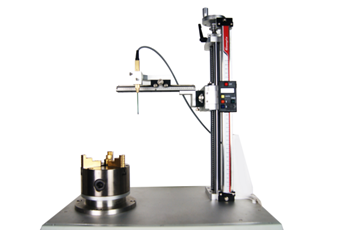

Clamping and positioning: Fix the raw materials on the machine tool to ensure the stability and accuracy of the machining process.

Rough machining: Remove excess material and form the general shape of the part.

Finishing: Refine the surface and contour of the part to achieve the precision and finish required by the design.

Special process treatments (if required): such as threading, chamfering, etc.

Unloading and cleaning: Remove the finished machined parts from the machine, and carry out subsequent processing such as deburring and cleaning.

3. Customized CNC furniture hardware parts service

Personalized design: Provide one-on-one design service to customize unique hardware parts according to customers’ needs.

Rapid prototyping: utilize CNC technology to produce samples quickly and shorten the product development cycle.

Mass production: efficiently meet the needs of large-volume orders to ensure delivery time.

Technical Support: Full technical support, including material selection, process optimization, etc.

After-sales service: provide warranty service to solve the problems encountered by customers in the process of use.

4. CNC furniture hardware parts material introduction

Stainless steel: strong corrosion resistance, smooth surface and easy to clean, suitable for kitchens, bathrooms and other humid environments.

Characteristics: high strength, wear-resistant, not easy to deform.

Characteristics: environmental protection and non-toxic, in line with food safety standards.

Characteristics: beautiful and generous, can maintain the luster for a long time.

Characteristics: easy to process, suitable for complex shape design.

Aluminum alloy: light and strong, with good thermal conductivity and plasticity.

Characteristics: corrosion resistance, the surface can be treated in a variety of ways.

Characteristics: moderate price, cost-effective.

Characteristics: easy to recycle and reuse, environmental friendly.

5. Different materials CNC furniture hardware parts features

Stainless steel handles:

Product: customized stainless steel handles

Data: tensile strength ≥ 500MPa, hardness HV ≤ 200

Data: Corrosion resistance grade ≥ 9 (according to ASTM B117 salt spray test)

Data: surface treatment optional plating, brushed, etc.

Aluminum alloy hinge:

Product: Customized aluminum alloy hinges

Data: light weight, about 1/3 of the same volume of stainless steel

Data: opening and closing times ≥ 100,000 times

Data: surface hardness ≥ HB80, strong wear resistance

Data: Damping effect can be adjusted according to demand

Customized CNC Furniture Hardware Parts Service FAQ

Q: How long does it take to customize CNC furniture hardware parts?

A: The customization time depends on the design complexity, material selection and production volume, usually it takes 7-15 working days from design confirmation to sample delivery, and the mass production time is negotiable.

Q: Can you provide multiple material options?

A: Yes, we offer a wide range of materials such as stainless steel, aluminum alloy, brass, etc. to meet different customers’ needs.

Q: How to ensure the machining accuracy?

A: We use advanced CNC machine tools and precision measuring equipment, combined with strict quality control processes, to ensure the machining accuracy of each part.

Q: Do you have after-sales service?

A: Of course, we provide comprehensive after-sales service, including repair and replacement within the warranty period and technical consultation.