I. Applications of Metal Gears and Racks

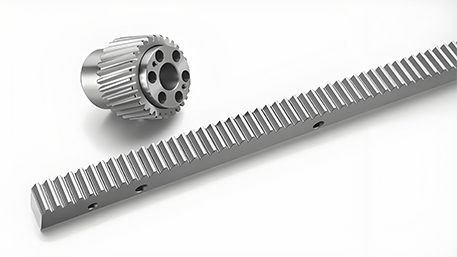

Metal gears and racks, as crucial components of transmission systems, play a pivotal role in the field of machining machinery. They convert rotational motion into linear motion through precise engagement or adjust different speeds and torques, thereby driving the operation of various mechanical equipment. Specifically, metal gears and racks are widely used in the following fields:

- CNC Machine Tools: Gears and racks are key components for achieving high-precision movement of the workbench. They work with motors to ensure extremely high precision and stability during machining.

- Automated Production Lines: Gears and racks are commonly used in conveyor belts, elevators, and other equipment to achieve precise displacement control, ensuring accurate movement of items on the production line and improving production efficiency.

- Heavy Machinery: In cranes, excavators, and other equipment, gears and racks are widely used in lifting systems, transmission systems, and other critical areas, capable of bearing enormous loads and ensuring the stable operation of mechanical equipment.

- Textile Industry: Gears and racks control the traction, tension, and conveyance of yarn, ensuring uniform distribution of yarn during the textile process and improving the quality of textiles.

- Packaging Machinery: Gears and racks control the conveyance, positioning, and cutting of packaging materials, ensuring precision and efficiency in the packaging process.

II. Advantages of Metal Gears and Racks

Metal gears and racks have significant advantages compared to other materials, mainly including the following:

- Durability: Metal gears exhibit excellent wear resistance and can withstand long-term wear without compromising performance.

- High Transmission Efficiency: Metal gear and rack transmission systems have higher transmission efficiency, reducing energy loss.

- Easily Controlled Internal Structure: The internal structure of metal gears is more stable, reducing the failure rate of the transmission system.

- High Strength: Metal gears have higher strength and hardness, capable of bearing greater loads.

- Greater Flexibility: Metal gears offer a larger transmission ratio, making them more versatile.

Xiamen Goldcattle’s Advantages in Producing Metal Gears and Racks:

- Advanced Production Equipment: Utilizes state-of-the-art CNC machines for production, ensuring high precision and quality of products.

- Extensive Production Experience: Possesses years of experience in producing metal gears and racks, enabling customized solutions for customers.

- Strict Quality Control: Conducts multiple quality inspections during the production process to ensure products meet specified technical requirements and quality standards.

- Excellent Customer Service: Provides comprehensive customer service, including technical support and after-sales service, ensuring customer satisfaction.

III. Comparison Table of Product Performance Among Multiple Companies

| Company Name | Material | Precision Grade | Wear Resistance | Transmission Efficiency | Customization Capability |

|---|---|---|---|---|---|

| Xiamen Goldcattle | High-Strength Alloy Steel | DIN 5e24~DIN 10e27 | High | High | Strong |

| Company A | Stainless Steel | DIN 6 | Medium | Medium | Average |

| Company B | Cast Iron | DIN 7 | Low | Low | Weak |

| Company C | Aluminum Alloy | DIN 8 | Moderately Low | Moderately High | Average |

(Note: The above data are for reference only, and specific performance may vary among different companies and products.)

IV. Specifications and Dimensions of Metal Gears and Racks

The specifications and dimensions of metal gears and racks can be customized according to customer needs. Common module numbers and sizes are as follows:

- Helical Racks:

- Module 1: 15151000 mm

- Module 1.5: 17171000 mm, 19191000 mm

- Module 2: 24241000 mm

- Module 2.5: 25251000 mm

- Module 3: 29291000 mm

- Module 4: 39391000 mm

- Module 5: 49391000 mm

- Module 6: 59491000 mm

- Module 8: 79791000 mm

- Module 10: 99991000 mm

- Straight Racks:

- Module 1: 1515999 mm

- Module 1.5: 1717999 mm, 1919999 mm

- Module 2: 24241005.31 mm

- Module 2.5: 25251005.31 mm

- Module 3: 29291017.90 mm

- Module 4: 39391005.31 mm

- Module 5: 49391005.31 mm

- Module 6: 59491017.90 mm

- Module 8: 79791005.31 mm

- Module 10: 99991005.31 mm

V. Customization Process for Metal Gears and Racks

- Needs Communication: Initially communicate with customers to understand their specific needs and applications.

- Design and Planning: Based on customer requirements, design appropriate tooth shapes and pitches, and plan the production process and techniques for machining.

- Material Selection: Select suitable metal materials according to design requirements, such as high-strength alloy steel.

- Production Preparation: Perform material cutting, grinding, and other operations to obtain rack blanks that meet requirements.

- Machining and Manufacturing: Conduct rough machining, semi-finishing, gear milling, heat treatment, finishing, and other steps to ensure product precision and quality.

- Grinding Process: Polish the rack surface to improve its smoothness and precision.

- Quality Inspection: Conduct a comprehensive inspection of the processed racks to ensure they meet specified technical requirements and quality standards.

- Packaging and Shipment: Package the inspected and qualified products and arrange for shipment.

Common Issues in Product Customization:

- Material Selection: Customers may not fully understand material properties and require explanations and suggestions from professionals.

- Precision Requirements: Customers may have unclear or overly high precision requirements, necessitating thorough communication with technical personnel.

- Delivery Schedule: Customers may have strict delivery requirements, necessitating reasonable arrangement of production schedules by the enterprise to meet demands.

- After-Sales Service: Customers may have concerns about after-sales service, requiring the enterprise to provide comprehensive after-sales support measures.

In summary, Xiamen Goldcattle has significant advantages in the production of metal gears and racks, capable of providing customers with high-quality, customized product solutions. Additionally, through a rigorous customization process and quality control measures, the company ensures that products meet customer needs and industry standards.