In modern manufacturing, customized CNC milling parts are playing an increasingly important role. These parts are no longer simple industrial components but the crystallization of high precision, high performance and individualized demands.

CNC milling technology, with its outstanding precision and flexibility, has become the ideal choice to meet various complex design requirements. Through the computer numerical control (CNC) system, milling machines can precisely cut raw materials according to pre-written programs, thereby manufacturing parts with various shapes and precise dimensions.

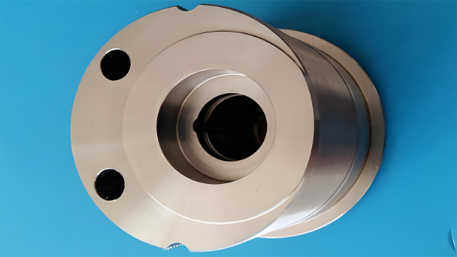

There are numerous advantages of customized CNC milling parts. The first is high precision, which can reach micron-level tolerance requirements, ensuring the accuracy and reliability of the parts during assembly and use. The second is the processing ability of complex shapes. Whether it’s the internal cavity, curved surface or special contour, it can all be easily achieved. Moreover, through customization, appropriate materials and processing techniques can be selected based on specific application scenarios and performance requirements to achieve the best effect.

During the customization process, the design link is crucial. Engineers utilize advanced computer-aided design (CAD) software to transform creativity and ideas into detailed three-dimensional models. This model not only shows the appearance of the part but also contains all the information such as dimensions, geometric features and process requirements.

Subsequently, programmers write precise CNC machining programs based on the design model. They need to consider numerous parameters such as tool paths, cutting speeds and feed rates to ensure the efficiency and quality of the machining process.

The choice of materials is also a key factor affecting the performance of customized parts. Common materials include aluminum alloys, stainless steel, titanium alloys, etc. Each material has unique mechanical properties and processing characteristics.

In actual processing, advanced CNC milling machines are equipped with high-performance tools and fixtures, which can perform cutting operations stably and rapidly. At the same time, multi-axis linkage technology enables the processing of multiple surfaces in one setup, greatly improving production efficiency and precision.

Customized CNC milling parts are widely used in aerospace, automotive, medical, electronics and other fields. In aerospace, high-strength and lightweight parts are the key to ensuring the performance and safety of aircraft; in the automotive industry, high-precision engine components and complex body structure parts are inseparable from CNC milling technology; in the medical field, precise medical device parts require extremely high precision and reliability.

In conclusion, customized CNC milling parts are an indispensable part of modern manufacturing. They combine innovative design with exquisite craftsmanship, providing high-quality and high-performance solutions for various industries and promoting the continuous progress and development of technology.