A Comprehensive Guide to Manufacturing High-Quality Plastic Molds for Concrete Flower Pots

Updated: December 15, 2025 | Manufacturing Guide | Professional Grade

The Growing Demand for Concrete Planters

In the field of horticultural decoration and home beautification, concrete cement planters are gradually becoming a popular gardening item due to their unique texture and style. The global market for concrete planters is projected to grow at a CAGR of 6.8% from 2025 to 2030.

The importance of custom concrete planter plastic molds, as the key tool for making such planters, cannot be overstated. This article provides a detailed analysis of material selection, production processes, application scenarios, customization procedures, and maintenance best practices.

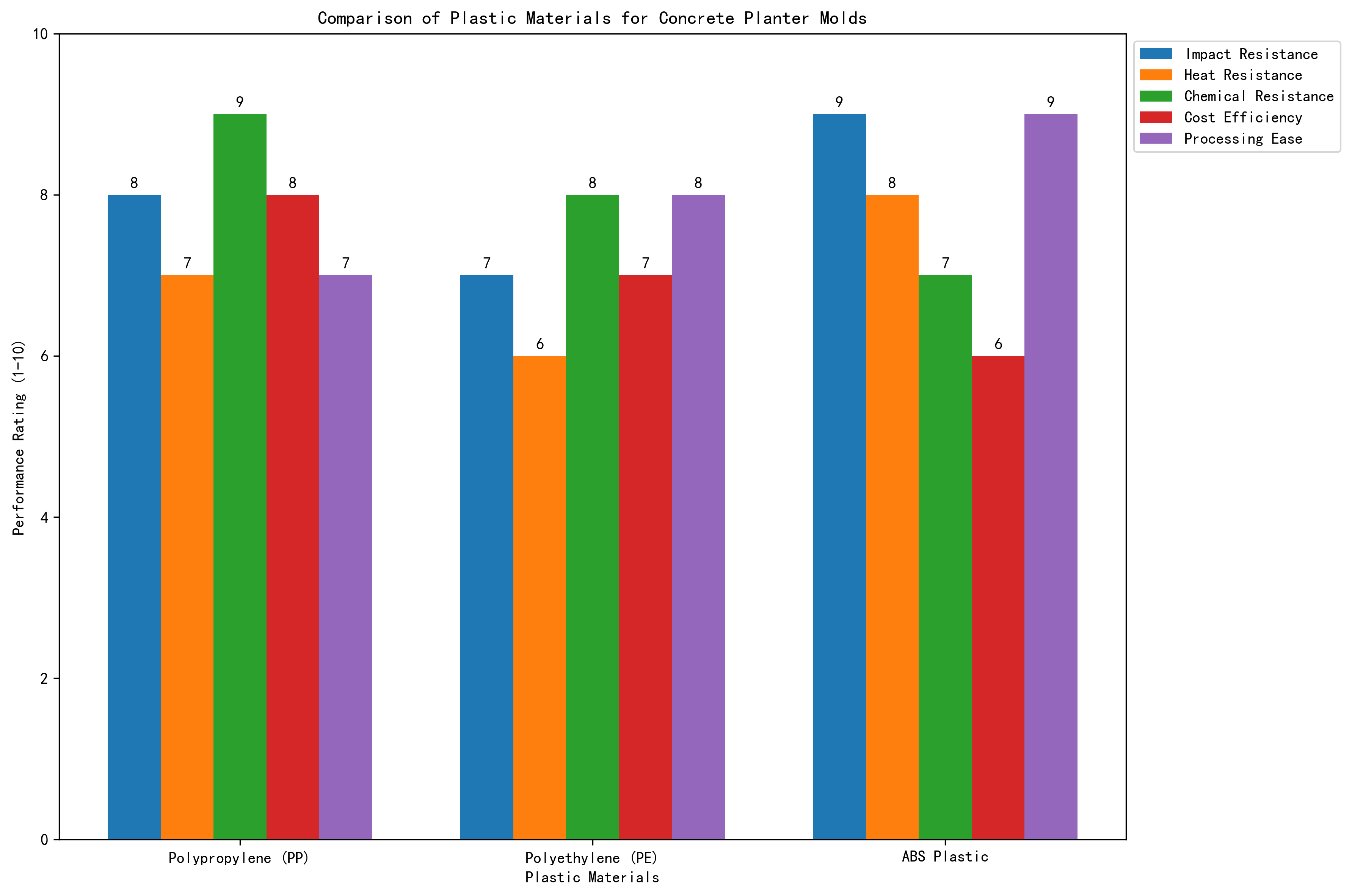

Material Selection for Plastic Molds

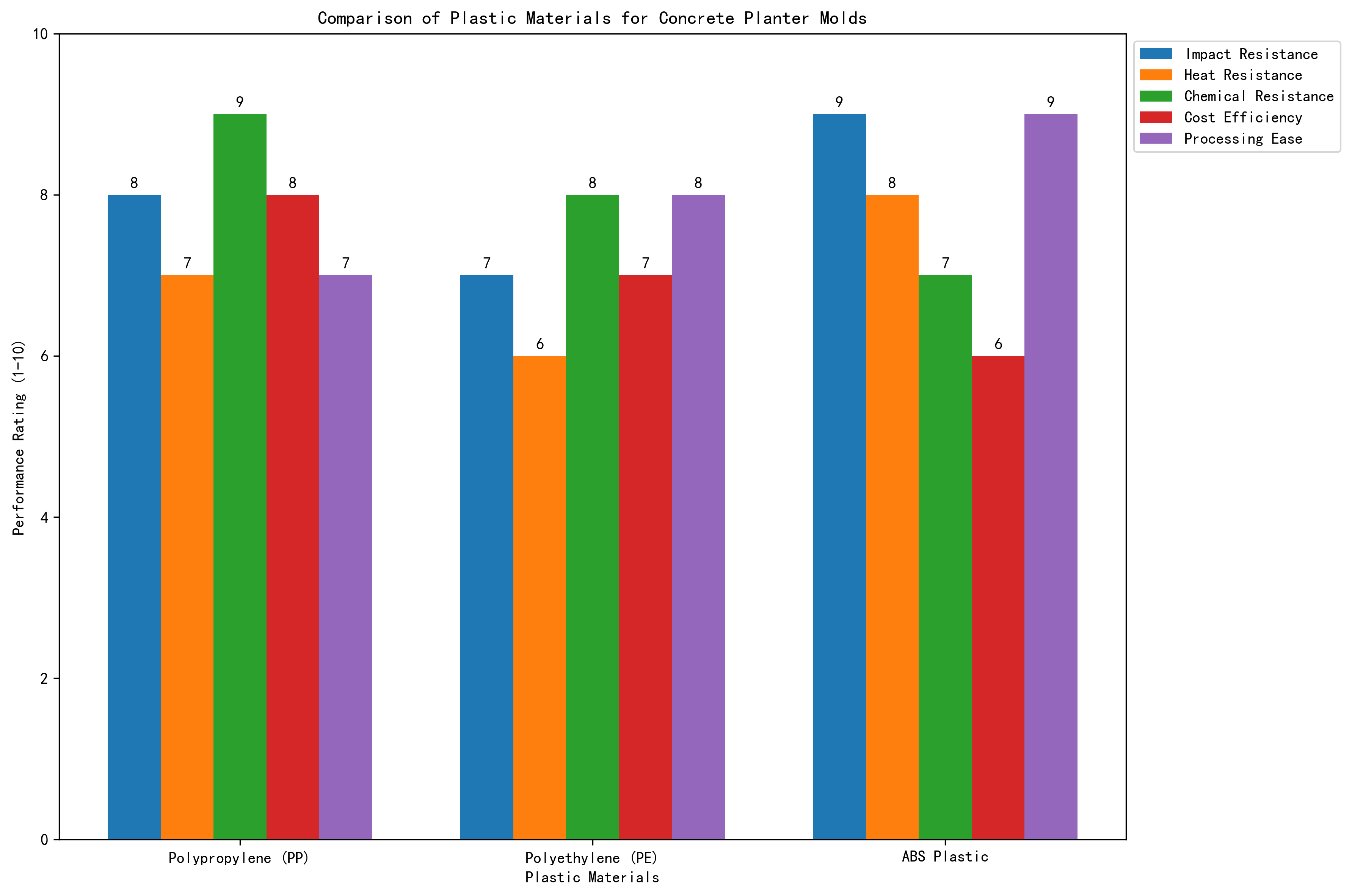

The material selection of custom concrete planter plastic mold is crucial, which is directly related to the service life of the mold, deformation resistance and production costs. Commonly used mold materials include polypropylene (PP), polyethylene (PE) and ABS plastic.

Polypropylene (PP)

- Excellent impact resistance

- Good heat resistance (100-120°C)

- Superior chemical resistance

- Brittle at low temperatures

Polyethylene (PE)

- Divided into HDPE and LDPE

- Good flexibility for complex shapes

- Excellent low-temperature performance

ABS Plastic

- High strength and toughness

- Excellent processing performance

- Resistant to cement slurry pressure

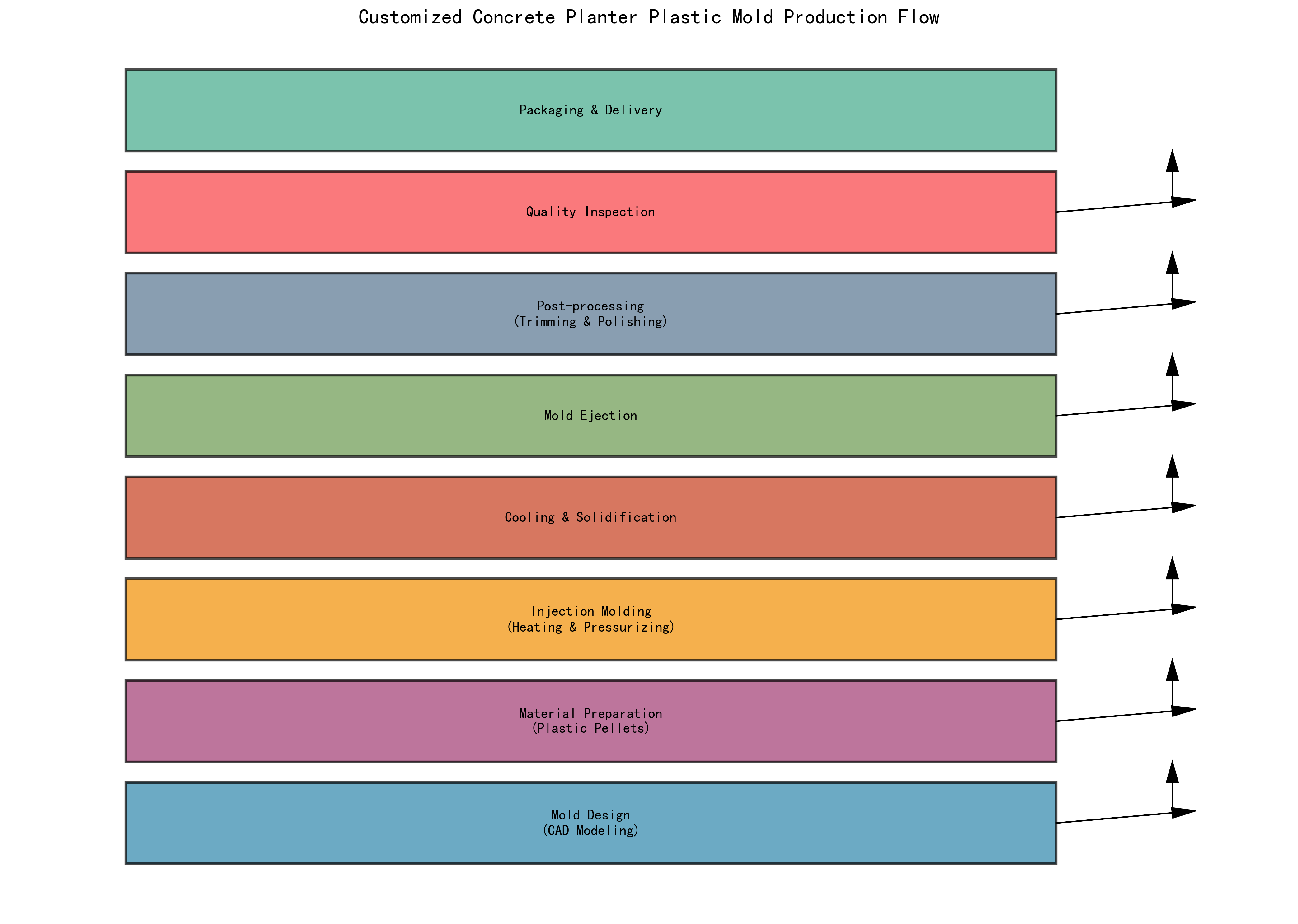

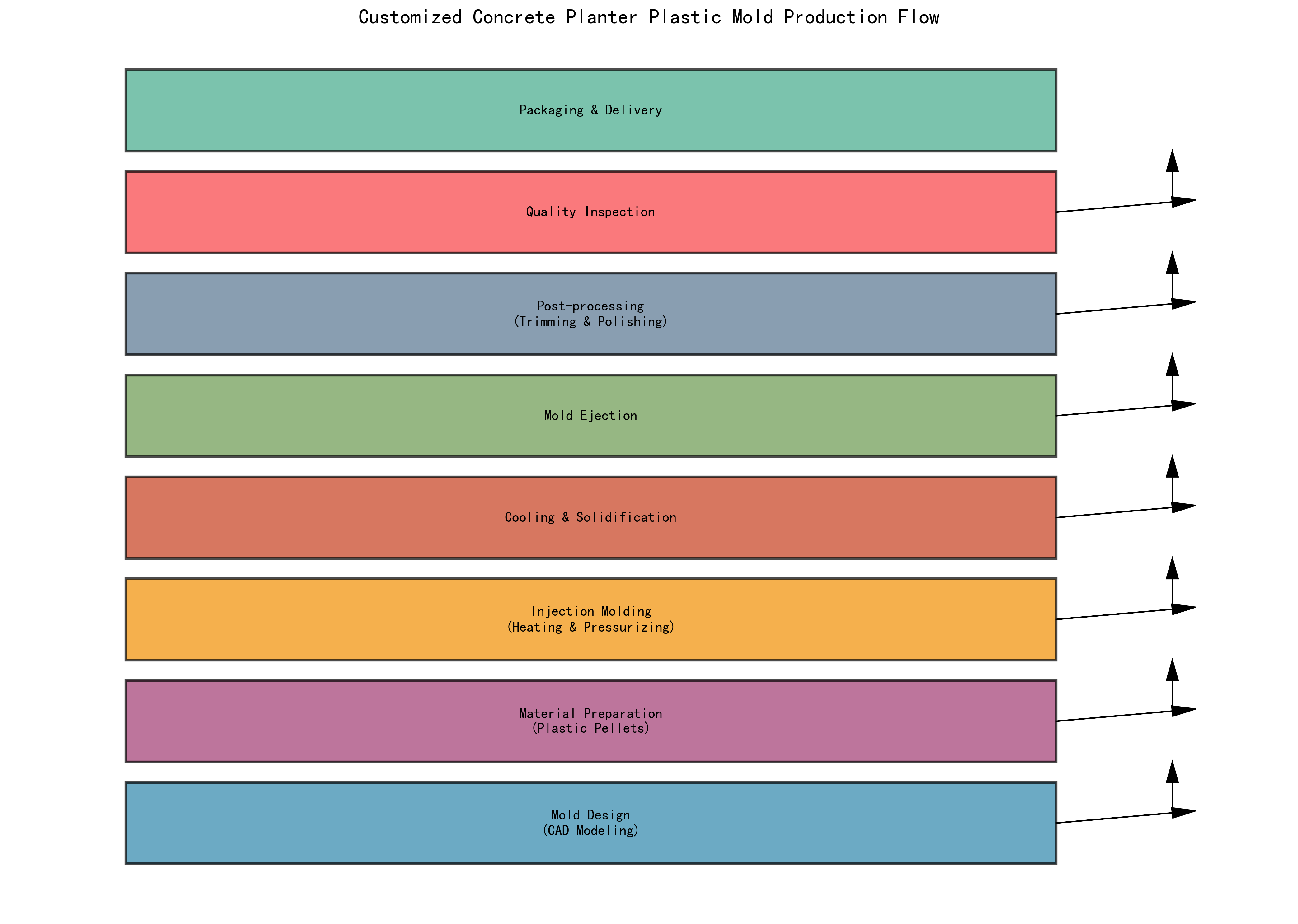

Production Process of Plastic Molds

The production process of customized concrete planter plastic mold is complex and delicate, requiring precise control of temperature, pressure, and timing to ensure high-quality results.

Key Production Steps

- Mold Design: CAD modeling based on customer requirements, considering shape, size, texture, and drainage holes.

- Material Preparation: Drying and mixing plastic pellets to improve injection molding efficiency and mold quality.

- Injection Molding: Heating plastic to molten state and injecting into mold under high pressure (1000-2000 bar).

- Cooling & Finishing: Controlled cooling followed by trimming, grinding, and quality inspection.

Application Scenarios

Concrete planters made using customized plastic molds are widely used in various fields, offering both aesthetic appeal and functional benefits.

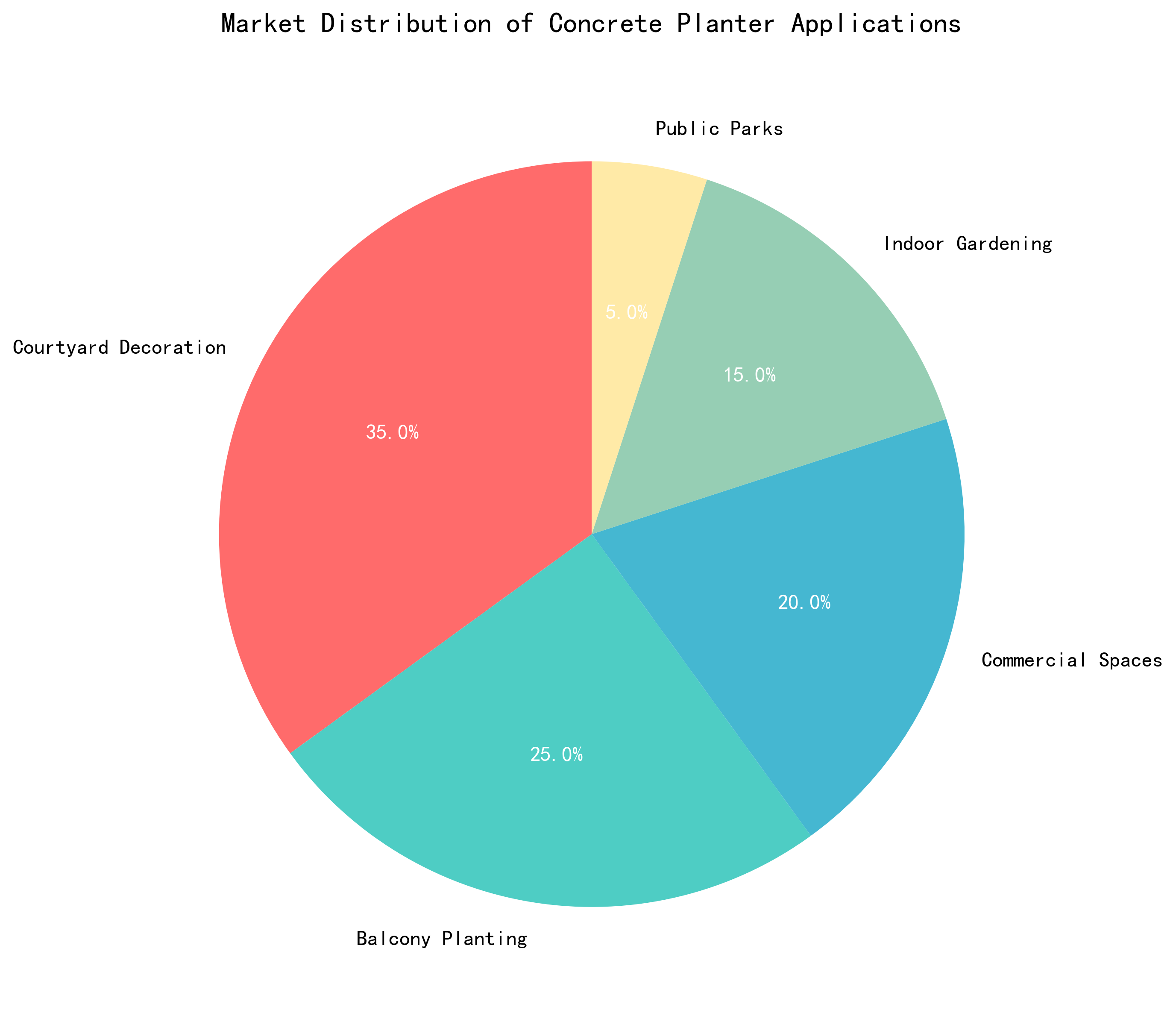

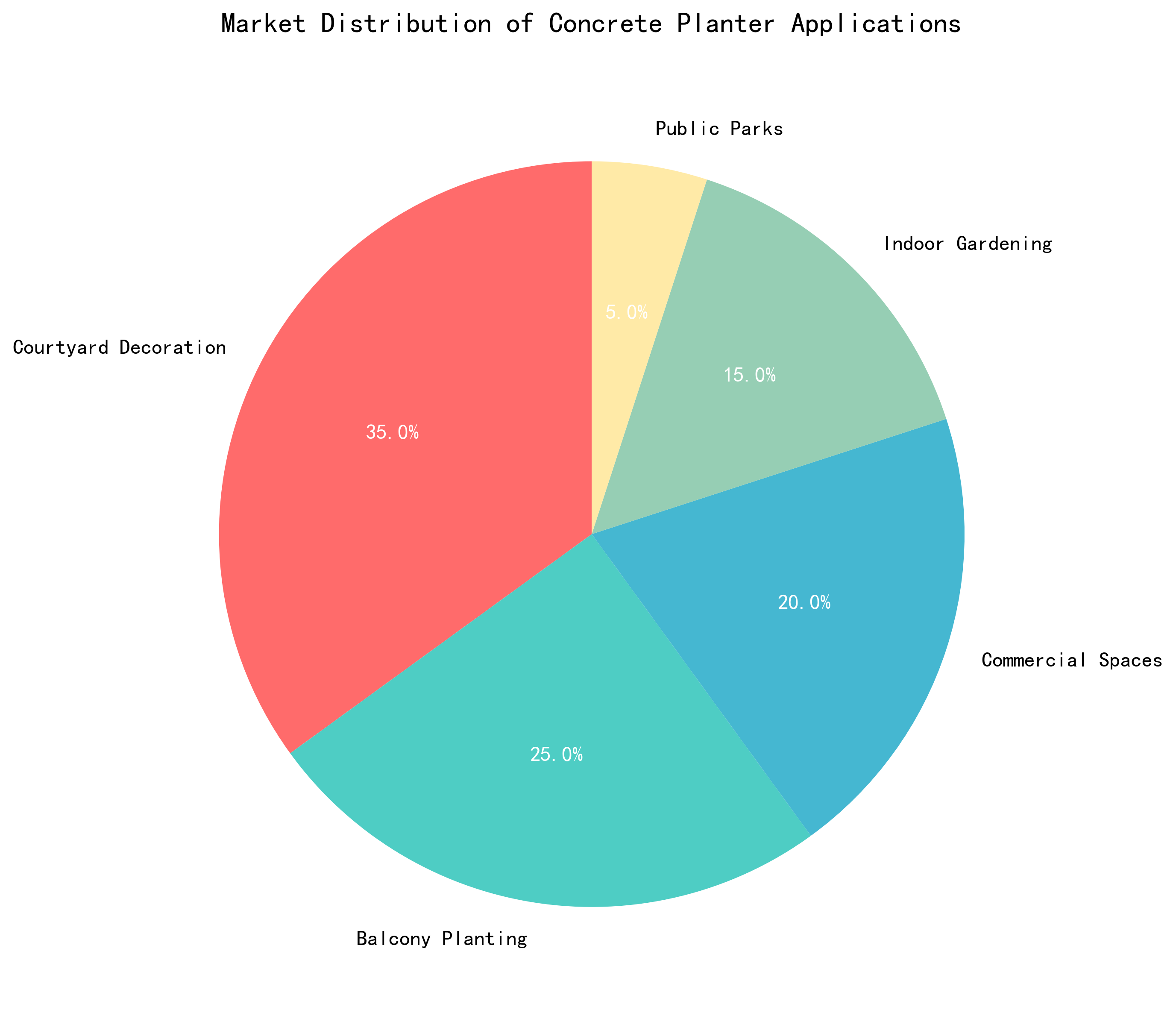

Courtyard Decoration (35% Market Share)

With unique texture and style, concrete planters become part of the courtyard landscape, complementing green plants and adding natural atmosphere.

Balcony Planting (25% Market Share)

Suitable for planting succulents, flowers and other small plants on balconies or terraces, offering both beauty and practicality.

Commercial Spaces (20% Market Share)

Placing cement planters in cafes, restaurants and retail spaces creates unique atmosphere and enhances the taste and class of the place.

Customization Process

Our standardized customization process ensures that every project meets the highest quality standards and customer expectations.

5-Step Customization Process

- Demand Communication: Clarify shape, size, texture, and quantity requirements

- Scheme Design: CAD modeling, material selection, process planning

- Quote Confirmation: Costing, quotation, contract signing

- Mold Production: Processing, injection molding, post-processing

- Quality Inspection: Dimensional checks, performance testing, certification

Stringent Quality Control Standards

- Dimensional accuracy: ±0.1mm tolerance

- Surface finish: Ra ≤ 1.6μm roughness

- Pressure resistance: up to 500kg load testing

- Temperature resistance: -40°C to 120°C testing

- Chemical resistance: cement slurry compatibility

- Durability: 10,000+ cycle testing

- ISO 9001:2015 certified production

- 100% inspection before shipment

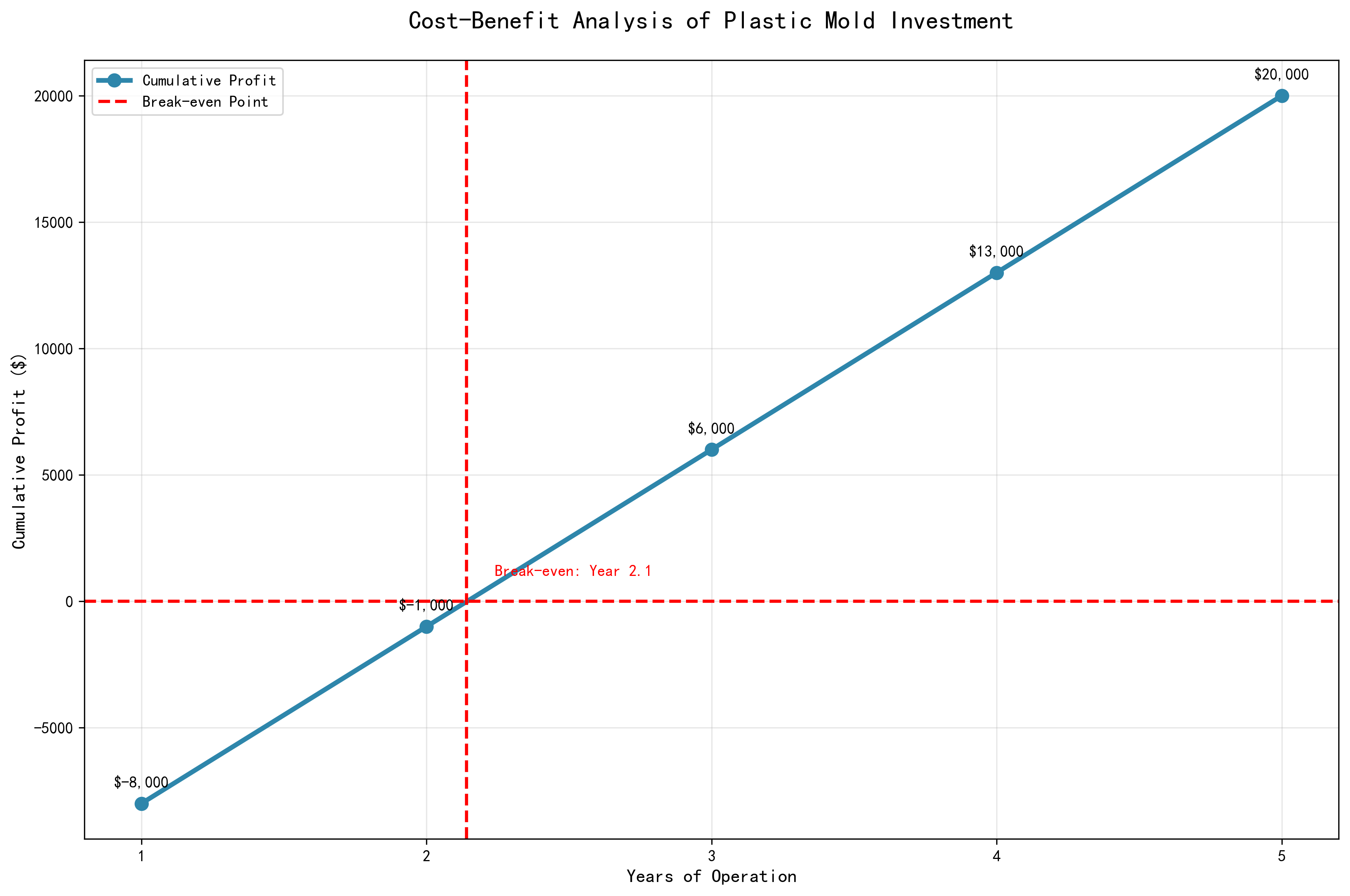

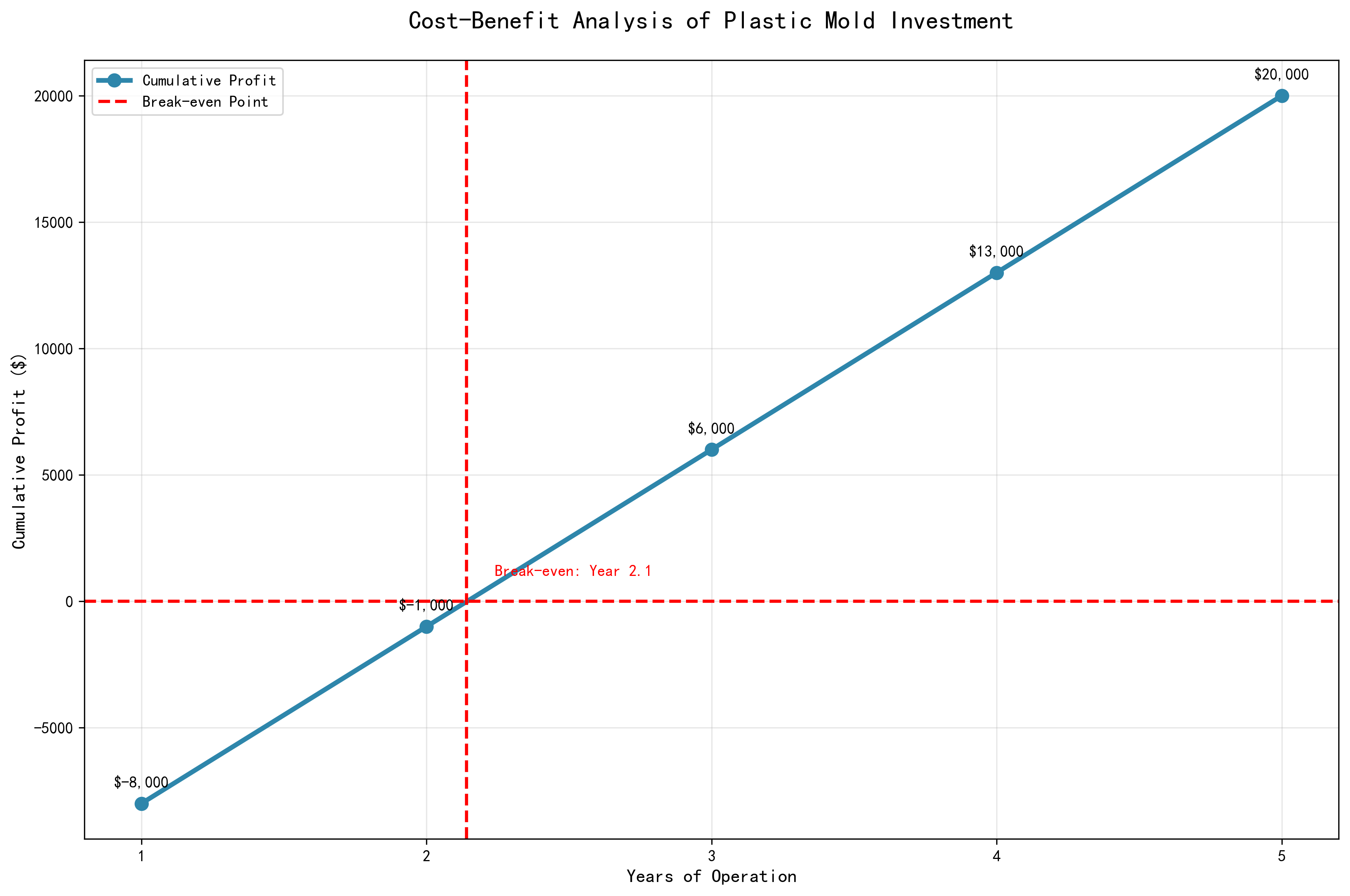

Cost-Benefit Analysis

Investing in high-quality plastic molds offers significant long-term benefits compared to traditional mold-making methods.

Cost Savings

- 30-50% lower production costs

- Reduced material waste (5-8%)

Efficiency Gains

- Higher precision (±0.1mm)

- Consistent quality output

- 24/7 production capability

Competitive Advantage

- Customization flexibility

- Enhanced brand reputation

Maintenance and Care

Proper maintenance is essential to prolong the service life of customized concrete planter plastic molds and ensure consistent production quality.

Regular Cleaning

Clean molds immediately after use to remove residual cement mortar. Use soft brushes or cloths to avoid scratching surfaces.

Routine Inspection

Check for loose connections, damage, or wear. Ensure drainage holes remain clear for proper functionality.

Proper Storage

Store in dry, ventilated areas away from direct sunlight. Apply protective agents for long-term storage.

Adequate Lubrication

Use appropriate lubricants to reduce friction and extend mold life. Choose lubricants based on material type.

Future Outlook

Customized concrete cement planter plastic molds represent a significant opportunity in the growing horticultural and home decoration markets. With the increasing demand for sustainable, durable, and aesthetically pleasing gardening products, the market for high-quality plastic molds is expected to continue its robust growth trajectory.

By leveraging advanced materials, precision manufacturing processes, and strict quality control, manufacturers can produce molds that meet the highest industry standards while delivering exceptional value to customers.

Contact Information

Xiamen Goldcattle Industrial & Trade Co., Ltd.

- Address: Xiamen, Fujian, China