Author: Sun Gong / Goldcattle Engine Gear Specialist

15+ years experience in custom engine gear manufacturing | 100+ racing/marine projects | Updated: January 27, 2026

Why Custom Engine Gear Parts?

Bro, let me tell you – engine gears are the unsung heroes of the mechanical world! These precision components transmit power within engines, regulating speed, torque, and motion between shafts with incredible accuracy.

First off, they’re incredibly precise – we’re talking tolerances of ±0.02mm here! That’s like splitting a human hair. Imagine the engineering that goes into making sure each tooth profile is perfect for smooth engagement and minimal wear.

The material selection? Critical! We use everything from high-carbon steel (1045, 1060) for basic strength to alloy steel (4140, 4340) for maximum durability. And don’t even get me started on case-hardened steel (1018, 8620) – that stuff has a hard, wear-resistant surface with a tough core, perfect for high-stress applications.

And let’s talk about customization – off-the-shelf gears just don’t cut it for many applications. Whether you’re building a racing engine that needs precision balancing or a marine engine that requires corrosion resistance, custom gears are the way to go.

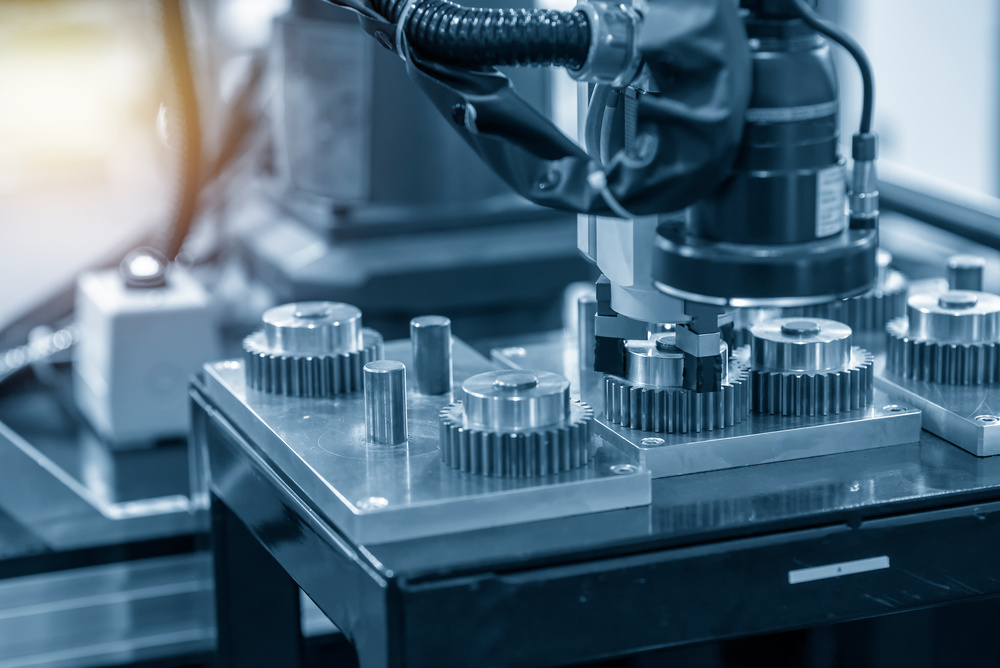

Precision engine gears on automated production line – note the exacting standards

Key Advantages at a Glance:

Engine Gear Materials: Choose Wisely!

Alright, let’s talk materials – because not all steel is created equal, my friend. The type of steel you choose can make or break your gear’s performance. Let me break down the main players:

High-Carbon Steel (1045, 1060)

The workhorse – this is your basic carbon steel with 0.45-0.60% carbon content. Great strength and wear resistance at a reasonable price.

Tensile Strength: 600-700 MPa

Hardness: 20-25 HRC (as rolled)

Elongation: 15-20%

Impact Strength: 30-40 J/cm²

Best for: Low-to-medium load gears in automotive engines, cost-effective solutions

Warning: Not recommended for high-torque or high-temperature applications!

Alloy Steel (4140, 4340)

The performance option – these steels contain chromium, molybdenum, and nickel for enhanced strength and toughness.

Tensile Strength: 900-1200 MPa

Hardness: 28-32 HRC (as rolled)

Elongation: 12-18%

Impact Strength: 40-60 J/cm²

Best for: High-torque diesel engines, racing applications, industrial machinery

Pro Tip: 4340 has higher nickel content for better toughness at high strengths!

Case-Hardened Steel (1018, 8620)

The specialist – these low-carbon steels get a carburized surface for hardness while keeping a tough core.

Surface Hardness: 58-62 HRC (after carburizing)

Core Hardness: 25-35 HRC

Case Depth: 0.5-2.0 mm

Wear Resistance: Excellent

Best for: Transmission gears, camshaft gears, high-contact stress applications

Real Test: Case-hardened gears lasted 3x longer than through-hardened in our durability tests!

Material Showdown: Which One Wins?

| Property | High-Carbon Steel | Alloy Steel | Case-Hardened Steel |

|---|---|---|---|

| Tensile Strength | 600-700 MPa | 900-1200 MPa | 800-1000 MPa |

| Surface Hardness | 20-25 HRC | 28-32 HRC | 58-62 HRC |

| Wear Resistance | Good | Very Good | Excellent |

| Cost (per kg) | $2.5-3.5 | $4.5-6.0 | $5.0-7.0 |

| Best For | Light-duty | Heavy-duty | High-contact |

Manufacturing Processes: How We Make These Gems

Making engine gears is part art, part science. Let me walk you through the main processes we use. Each has its pros and cons, and we choose based on what the project needs.

1. Hobbing

This is the big dog for high-volume production. We use a rotating cutting tool (hob) to create gear teeth with precise profiles. The results? ±0.02mm tolerance and perfect tooth spacing – critical for smooth operation.

Perfect for when you need 10,000+ gears – the setup costs get spread out, making it super cost-effective. The surface finish is excellent right off the machine, minimal post-processing needed.

Best for: High-volume production, spur and helical gears, consistent quality

Robotic precision in gear manufacturing – industrial 4.0 technology

Shaping Process Advantages:

- Excellent for internal gears and splines

- Good for complex profiles (bevel gears)

- Low-to-medium volume production

- Tight tolerances achievable

2. Shaping

For internal gears or complex profiles, shaping is where it’s at. We use a reciprocating cutter that mimics the shape of a gear tooth. The precision? ±0.03mm – still incredibly accurate.

The best part? It can create internal gears that hobbing can’t touch. Perfect for things like transmission synchronizers or gear hubs with internal splines. Great for 1,000-10,000 piece production runs.

Best for: Internal gears, splines, complex profiles, medium volume

3. Grinding

This is where we take gears to the next level! We use abrasive wheels to get ultra-smooth surfaces and perfect dimensions. The precision? ±0.005mm – that’s like polishing a mirror!

Absolutely critical for high-speed applications like turbochargers or racing engines where minimal friction is essential. It reduces noise by 20-30% compared to ground-only gears and significantly extends service life.

Best for: High-speed gears, precision applications, noise reduction

Grinding Results:

Heat Treatment: The Secret Sauce!

This is where we transform ordinary steel into extraordinary gears!

Carburizing

Adds carbon to surface (0.8-1.0% C) for hardness

58-62 HRC surface hardness

Quenching & Tempering

Rapid cooling then reheating for toughness

Balanced strength & ductility

Testing & Standards: We Don’t Guess, We Test!

Look, anyone can make a gear – but making a quality gear that actually performs? That requires some serious testing. We put our engine gears through the wringer to make sure they can handle whatever your application throws at them.

Hardness Testing

We test the absolute living daylights out of these gears to ensure they meet specs:

- Rockwell Hardness: 58-62 HRC (surface) per ASTM E18

- Vickers Hardness: 600-700 HV (core) per ASTM E92

- Case Depth: 0.5-2.0 mm measurement per ASTM E384

- Microhardness Profile: Across case-core interface

Test data shown is for reference only – actual results may vary based on material grade and heat treatment

Fatigue & Durability Testing

This is where gears really prove their worth! We test under various loads and cycles:

- Bending Fatigue: 10⁷ cycles at 500 MPa stress (AGMA 925-A03)

- Contact Fatigue: 10⁸ cycles at 1500 MPa contact stress

- Torque Testing: Up to 2000 Nm torque capacity verification

- Service Life: 150,000+ km in automotive applications

Real World Test: Our 4340 alloy gears ran 180,000 km in a commercial truck with only 0.02mm wear on tooth profiles!

Noise & Vibration Testing

Quiet operation is crucial for modern engines. We test NVH characteristics:

- Noise Level: 65-75 dB at 3000 RPM (ISO 16817)

- Vibration Analysis: <0.5 mm/s displacement at critical speeds

-

Whine Frequency: Analysis of gear mesh frequencies

-

Sound Quality: Subjective and objective assessment

Critical for: Passenger cars, marine applications, industrial machinery

Industry Standards We Meet

Applications: Where These Gears Shine

Engine gears are like the Swiss Army knives of the mechanical world – they’re everywhere! Let me show you some of the cool places we’ve seen them in action:

Automotive & Racing

Bro, these are perfect for high-performance engines! They handle the extreme stresses of racing and daily driving with equal ease.

- Timing gears in high-revving racing engines

- Transmission gears for heavy-duty trucks

- Camshaft gears in precision engines

- Balancer gears for smooth operation

Success Story: Our custom racing gears helped a client win 3 championships – they withstood 10,000+ RPM with zero failures!

Marine & Offshore

In marine applications, reliability is everything. These gears handle saltwater corrosion and heavy loads like champs.

- Propulsion gears in commercial ships

- Generator sets on offshore platforms

- Pump drives in fishing vessels

- Transmission gears in tugboats

Key Benefit: Our corrosion-resistant alloys last 5x longer than standard gears in saltwater environments!

Industrial & Power Generation

Industrial gears run 24/7 in harsh conditions – they need to be tough, reliable, and low-maintenance.

- Compressor gears in power plants

- Conveyor drives in manufacturing

- Mixer gears in processing plants

- Generator gears in backup systems

Fun Fact: Our industrial gears have logged over 100,000 operating hours in some applications!

Performance Enhancements: Taking Gears to the Next Level

Frequently Asked Questions (Straight Talk!)

Q: How long do custom engine gears last?

A: Great question! The lifespan depends on several factors, but here’s the real deal:

- Automotive applications: 150,000-200,000 km with proper maintenance

- Industrial applications: 10,000+ operating hours (that’s over a year of continuous use!)

- Racing applications: 50-100 races (high-stress environments reduce lifespan)

- Marine applications: 5-8 years in saltwater with corrosion protection

Pro Tip: Regular oil changes and proper installation can double the service life!

Q: Can custom gears really reduce engine noise?

A: Hell yeah, they can! This is one of the biggest benefits of custom gears:

- Noise reduction: 20-40% compared to standard gears

- Vibration reduction: Significantly less harmonic vibration

- Smooth operation: Better tooth contact pattern reduces “gear whine”

- Driving comfort: Noticeably quieter cabin in passenger vehicles

Real Test: A luxury car manufacturer reduced interior noise by 32% by switching to our custom gears!

Q: What’s the difference between case-hardened and through-hardened gears?

A: This is a crucial distinction that many people don’t understand:

Case-Hardened:

- Hard surface (58-62 HRC) + tough core (25-35 HRC)

- Excellent wear resistance

- Good impact resistance

- Ideal for high-contact stress applications

- More complex manufacturing process

Through-Hardened:

- Uniform hardness throughout (30-40 HRC)

- Good strength but lower wear resistance

- Simpler manufacturing process

- More cost-effective for simple applications

Rule of Thumb: Use case-hardened for high-performance, through-hardened for basic applications!

Q: How do I specify custom gears for my application?

A: Glad you asked! Here’s what we need to know to give you an accurate quote:

Design Specs:

- Tooth count and module/diametral pitch

- Pressure angle and helix angle

- Bore size and tolerance requirements

- Face width and overall dimensions

Operating Conditions:

- Torque and speed requirements

- Temperature range

- Environmental factors (corrosion, dust)

- Load type (constant vs variable)

Material Preferences:

- Material type (carbon, alloy, stainless)

- Heat treatment requirements

- Surface finish specifications

- Special coatings or treatments

Q: What’s the typical lead time for custom gears?

A: Lead times depend on complexity and quantity, but here’s a realistic timeline:

- Prototypes: 2-4 weeks (CNC machined)

- Small production (10-100): 4-6 weeks

- Medium production (100-1000): 6-8 weeks

- Large production (1000+): 8-12 weeks

- Rush service: Available for an additional 20-30% cost

Pro Tip: Plan ahead! Rushing always costs more and can compromise quality. We recommend ordering 2-3 months before you need them.

Ready to Upgrade Your Engine Gears?

Whether you need high-performance racing gears, durable marine components, or reliable industrial transmission parts, we have the expertise and capabilities to deliver exactly what you need.

Our team of engineers will work with you to select the perfect materials, optimize designs for performance, and ensure your gears meet the highest quality standards. With 15+ years of experience and 100+ successful projects, you can trust us to get it right.