In the era of pursuing personalization and high performance, custom headlight housings have become an important choice to enhance vehicle appearance and driving safety. We provide professional customized lamp housings service, aiming to satisfy every car owner’s pursuit of unique style and excellent quality. Through exquisite craftsmanship, innovative design and diversified material choices, we create a unique visual feast for your car.

1.Lamp housing production process

Design Confirmation: According to the customer’s demand, carry out the preliminary design of headlight shell, including shape, size, style, etc., and confirm the design with the customer.

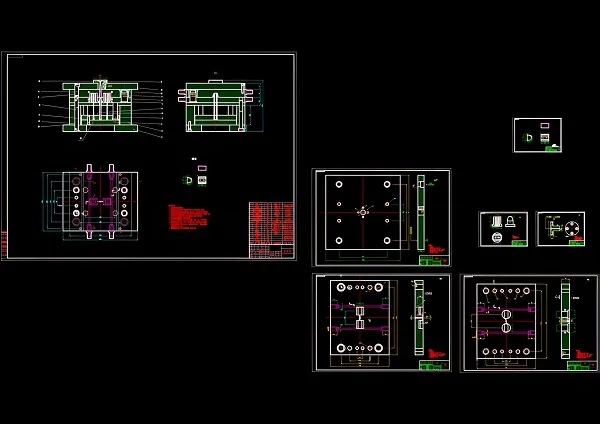

Mould making: according to the design drawings, make the injection mold or die-casting mold of the lamp housing to ensure the precision and durability.

Material Preparation: Select high quality raw materials and carry out pre-treatment, such as drying and cutting, etc., to prepare for production.

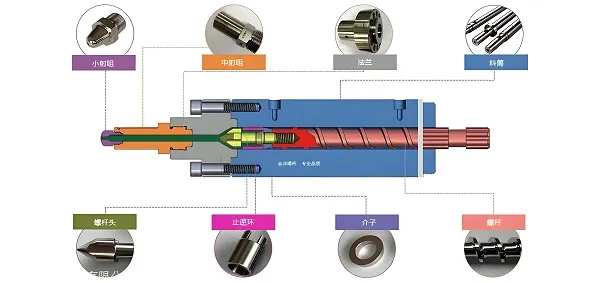

Injection/Die-casting Molding: The treated material is injected into the mold and molded through high temperature and high pressure to form the initial shape of the headlight housing.

Post-processing: Sanding, polishing, painting and other surface treatments are performed on the molded lamp housing to enhance the appearance texture and weather resistance.

Assembling and testing: install the lamp components in the shell, conduct functional testing and optical adjustment to ensure that the performance is up to standard.

Quality Inspection: Strict quality inspection process to ensure that each lamp housing meets the high standard requirements.

Packaging and delivery: qualified products are carefully packaged and safely delivered to customers.

2.Lamp shell processing steps

Rough machining: Remove the excess material after molding, and trim the shape initially.

Finishing: Adopt high-precision equipment to polish the lamp shell finely to ensure the surface is smooth and flawless.

Surface treatment: according to the customer’s needs, paint, electroplating, sandblasting and other surface treatment processes to enhance the visual effect.

Detailed treatment: special treatment for lamp edges and seams to enhance sealing and aesthetics.

Assembly Preparation: Reserve precise mounting positions for the lamp components to ensure smooth assembly.

3.Customized lamp housing service

One-on-one design service: professional designer team to provide personalized design solutions according to customer needs.

Diversified material choices: Provide a variety of material choices such as ABS, PC, carbon fiber, etc. to meet different needs.

Rapid sampling: Efficient production process ensures rapid completion of sample production for customer confirmation.

Quality Assurance: Strict quality control system ensures that each product meets the highest standards in the industry.

Worry-free after-sales service: Provide perfect after-sales service to solve any problems encountered by customers in the process of use.

4.Lamp housing material introduction

ABS material: lightweight, high strength, impact resistance, easy to process molding, is the common material for headlight housing.

Characteristics: good weather resistance, not easy to aging; surface plasticity, suitable for a variety of surface treatment process.

PC material: high transparency, strong UV resistance, suitable for the production of high brightness lamp housing.

Characteristics: excellent heat resistance, not easy to deform; good toughness, even if the impact is not easy to rupture.

Carbon fiber: lightweight, high strength, high rigidity, ideal for the pursuit of extreme performance and lightweight.

Characteristics: excellent fatigue resistance, long-term use can still maintain excellent performance; unique texture texture, enhance the vehicle grade.

Aluminum alloy: good heat dissipation performance, suitable for high-power LED lamps, while giving the lamp shell metal texture.

Characteristics: strong corrosion resistance, long service life; easy to process into complex shapes to meet diversified design needs.

Characteristics of different materials for headlight housings

| Material | Weight (g) | Heat Resistance (°C) | Light Transmittance (%) | Impact Resistance |

| ABS | Light | 80-100 | N/A | Excellent |

| PC | Moderate | 120-130 | High (>90%) | Good |

| Carbon Fiber | Very Light | High (>200) | N/A | Superior |

| Aluminum Alloy | Moderate | High (>200) | N/A | Good |

Customized Headlight Housing Service FAQ

Q: How long does it take to customize a headlight housing?

A: The customization time varies depending on the complexity of the design and the choice of materials. Generally, it takes 2-4 weeks from the design confirmation to the delivery of the finished product.

Q: How do you guarantee the quality of customized headlight housings?

A: We have a strict quality control system, from raw material purchasing to finished product delivery, every step of the process is strictly inspected.

Q: Can you provide samples for confirmation?

A: Yes, we can quickly make samples according to the design for customers’ confirmation to ensure that the final product meets the expectation.

Q: Does the customized lamp housing affect the function of the original car?

A: No, we make sure that the customized lamp housings are perfectly adapted to the original lamp components without affecting their normal function and use.

Q: What does after-sales service include?

A: After-sales service includes product warranty, installation instruction, question and answer, and necessary maintenance services, etc. to ensure that customers use worry-free.