Author: Chen

15+ years experience in custom nylon gear manufacturing | Updated: January 27, 2026

Why Custom Nylon Gear Parts?

Bro, let me tell you – nylon gears are absolute game-changers in the engineering world! These polymer-based components transmit motion and power in machinery with some serious advantages over traditional metal gears.

First off, they’re lightweight – like, 1/6 the weight of steel and 1/3 the weight of aluminum. Imagine the energy savings in rotating machinery! And don’t even get me started on the noise reduction – these babies run 30-50% quieter than metal gears. Perfect for medical devices or office equipment where noise matters.

The self-lubricating properties? Unreal. That low coefficient of friction (0.1-0.3) means less wear and tear, less maintenance, and longer service life. And their flexibility? They absorb shocks like a pro, making them way more resistant to impact damage than brittle metal alternatives.

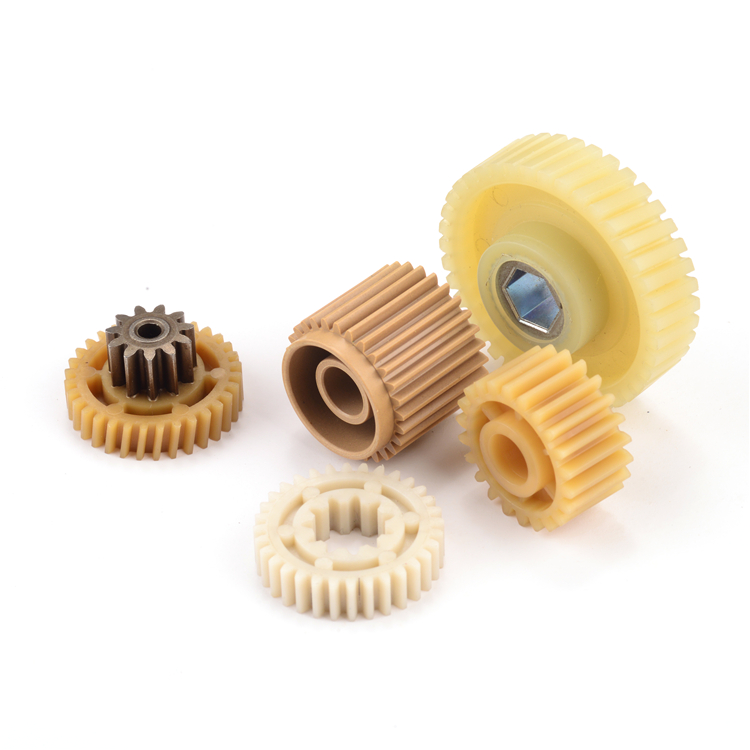

Different types of nylon gears – from small precision gears to large industrial sprockets

Key Advantages at a Glance:

Nylon Gear Materials: Choose Wisely!

Alright, let’s talk materials – because not all nylon is created equal, my friend. The type of nylon you choose can make or break your gear’s performance. Let me break down the main players:

PA6 (Polyamide 6)

The all-rounder – this is your basic nylon workhorse. Great impact resistance, good flexibility, and easy to machine.

Tensile Strength: 62 MPa

Density: 1.14 g/cm³

Moisture Absorption: ~3.5%

Temp Range: -40°C to 100°C

Best for: Gears, bushings, structural components needing resilience

PA66 (Polyamide 66)

The high-performance option – better heat resistance and mechanical strength than PA6.

Tensile Strength: 82 MPa

Density: 1.15 g/cm³

Moisture Absorption: ~2.5%

Temp Range: -40°C to 120°C

Best for: High-load applications, automotive parts, electrical components

Glass-Filled Nylon (10-30%)

The heavyweight champion – glass fibers add serious rigidity and strength for high-load situations.

Tensile Strength: 105 MPa

Density: 1.35 g/cm³

Moisture Absorption: ~1.5%

Temp Range: -40°C to 150°C

Best for: Industrial gears, conveyor systems, heavy machinery

Pro Tip from the Pros:

Hey, listen up – moisture absorption is no joke with nylon! PA6 absorbs about 3.5% moisture, which can affect dimensions. If you’re using these in humid environments, consider moisture-stabilized grades or PA66 which only absorbs ~2.5%. Trust me, I’ve seen too many projects fail because someone ignored this little detail!

Manufacturing Processes: How We Make These Gems

Making nylon gears is part art, part science. Let me walk you through the main processes we use. Each has its pros and cons, and we choose based on what the project needs.

1. Injection Molding

This is the big dog for high-volume production. We melt nylon resin and inject it into precision molds under pressure. The results? Complex gears with tight tolerances (±0.05mm). Insane consistency too – every gear comes out identical.

Perfect for when you need 10,000+ gears – the mold costs get spread out, making it super cost-effective. The tooth profiles are spot-on, and material properties are consistent throughout the part.

Best for: High-volume production, complex geometries, consistent quality

Injection molded nylon gears – note the precision tooth profiles

CNC machined nylon gears – tight tolerances and perfect finishes

2. CNC Machining

For low-volume or prototype work, CNC machining is where it’s at. We cut gears from solid nylon blocks using computer-controlled tools. The precision? ±0.02mm – that’s like splitting a human hair!

The best part? Quick modifications. If you need to tweak a design, we can adjust the CNC program and have a new part in hours, not days. Perfect for testing different designs or when you only need 1-100 pieces.

Best for: Prototypes, low-volume production, quick design changes

3. 3D Printing

Now we’re talking cutting-edge! 3D printing builds gears layer-by-layer from nylon filaments or powders. This is amazing for complex geometries that would be impossible with traditional methods – like internal lubrication channels or lightweight lattice structures.

Great for rapid prototyping – you can go from CAD model to physical part in hours. The surface finish isn’t quite as good as CNC or injection molding, but for testing form and fit? It’s perfect.

Best for: Complex geometries, rapid prototyping, low-volume custom parts

3D Printing Advantages:

- Complex internal structures

- No tooling costs

- On-demand production

- Lightweight designs

- Quick turnaround

Process Comparison: Which One’s Right For You?

| Process | Tolerance | Volume | Lead Time | Cost |

|---|---|---|---|---|

| Injection Molding | ±0.05mm | High (10k+) | 2-4 weeks | Low per unit |

| CNC Machining | ±0.02mm | Low (1-100) | 1-3 days | High per unit |

| 3D Printing | ±0.1mm | Very Low (1-10) | Hours | Very high per unit |

Testing & Standards: We Don’t Guess, We Test!

Look, anyone can make a gear – but making a quality gear that actually performs? That requires some serious testing. We put our nylon gears through the wringer to make sure they can handle whatever your application throws at them.

Mechanical Testing

We test the absolute living daylights out of these gears to ensure they meet specs:

- Tensile Strength: Up to 105 MPa (ASTM D638)

- Flexural Modulus: Up to 2850 MPa (ASTM D790)

- Impact Strength: 0.8-1.2 ft-lbs/in (ASTM D256)

- Hardness: R110-R121 (Rockwell R, ASTM D785)

- Compressive Strength: 7.5 Kg/mm² at 10% deformation (ASTM D695)

Test data shown is for reference only – actual results may vary based on material grade and processing conditions

Wear & Friction Testing

This is where nylon really shines! We test under various loads and speeds:

- Coefficient of Friction: 0.21-0.28 (dry)

- Wear Rate: 0.5-2.0 x 10⁻⁸ mm³/Nm

- Service Life: 5,000-15,000+ operating hours

- PV Limit: 100,000 psi-fpm (varies by grade)

Real World Test: Our PA66+30% glass gears ran 12,000 hours in a conveyor application with only 0.03mm wear on the tooth profile!

Environmental Testing

Gears don’t live in perfect conditions, so we test them in real-world environments:

- Temperature Range: -40°C to 150°C

- Moisture Resistance: Tested at 95% RH for 1000 hours

- Chemical Resistance: Oils, greases, solvents, fuels

- UV Stability: 500+ hours QUV exposure

Pro Tip: For outdoor applications, use UV-stabilized grades to prevent degradation!

Industry Standards We Meet

Applications: Where These Gears Shine

Nylon gears are like the Swiss Army knives of the mechanical world – they’re everywhere! Let me show you some of the cool places we’ve seen them in action:

Food & Beverage Industry

Bro, these are perfect for food processing! They’re corrosion-resistant, lubricant-free (so no contamination), and meet FDA standards (21 CFR 177.1500).

- Conveyor systems for packaging

- Mixing equipment

- Filling machines

- Canning equipment

- Bakery machinery

Success Story: A major bakery replaced metal gears with our food-grade PA66 gears – reduced maintenance by 70% and eliminated lubricant contamination issues!

Medical Equipment

In medical devices, precision and cleanliness are everything. Nylon gears deliver both – they’re quiet, non-magnetic, and easy to sterilize.

- MRI machines (non-magnetic!)

- Surgical tools

- Patient lifts

- Dialysis equipment

- Lab automation

Key Benefit: Nylon’s non-magnetic properties make it safe for MRI environments where metal would cause interference.

Automotive Sector

Cars are all about weight reduction and fuel efficiency – nylon gears help with both! They’re used in all sorts of automotive applications.

- Window regulators

- Seat adjusters

- Windshield wiper systems

- Throttle bodies

- HVAC systems

Fun Fact: Using nylon gears in a car’s window system reduces weight by up to 50% compared to metal alternatives!

Cool Niche Applications You Might Not Expect!

Performance Enhancements: Taking Gears to the Next Level

Okay, so basic nylon gears are great – but what if you need even more performance? We’ve got you covered with these awesome enhancements:

Glass/Carbon Fiber Reinforcement

Adding 10-30% glass fibers is like giving your gears superpowers! Check out these improvements:

- Tensile Strength: +50-100%

- Flexural Modulus: +200-300%

- Wear Resistance: +40-60%

- Heat Deflection Temp: +30-50°C

Perfect for: High-load industrial applications, conveyor systems, heavy machinery

Solid Lubricant Infusion

We can add PTFE, molybdenum disulfide (MoS₂), or graphite to make gears even more slippery:

- Friction Coefficient: -30-40%

- Wear Rate: -50-70%

- Service Life: +100-200%

- Maintenance: Significantly reduced

Real Test: PTFE-infused gears ran 2x longer than standard nylon in a high-speed application!

UV Stabilization

For outdoor applications, UV stabilizers prevent degradation from sunlight:

- UV Resistance: 500+ hours QUV exposure

- Color Stability: Minimal fading

- Mechanical Properties: Maintained over time

- Service Life: +300-500% outdoors

Critical for: Lawnmowers, irrigation systems, outdoor machinery

Dimensional Stability Treatments

Moisture can affect nylon dimensions, but we have solutions:

Annealing Process:

- Heats gears to 80-100°C for 2-4 hours

- Reduces post-production shrinkage by 50-70%

- Improves stability in temperature-fluctuating environments

- Relieves internal stresses from molding/machining

Moisture Stabilization:

- Controlled conditioning to reach equilibrium moisture content

- Prevents dimensional changes in service

- Typically 2-4% moisture by weight

- Done in humidity-controlled chambers

Frequently Asked Questions (And Some Honest Answers!)

Q: What’s the maximum load nylon gears can handle?

A: Great question! It depends on the material and design, but here’s the real deal:

- Unreinforced nylon (PA6/PA66): Up to 500 N per tooth

- Glass-filled nylon (30% glass): 1,500-2,000 N per tooth

- Important: At temperatures over 80°C, load capacity drops by about 20-30%

Pro Tip: Always derate by 20% for safety factors in critical applications!

Q: How do nylon gears compare to metal gears in service life?

A: This is where nylon surprises a lot of people! In the right applications:

- Low-load, clean environments: Nylon gears often match or exceed metal gear life (5,000-10,000+ hours)

- Wet or chemical environments: Nylon outlasts metal by 2-3x because it doesn’t corrode

- Heavy loads: Metal is better, but nylon can still hold its own with proper reinforcement

Real Example: A customer replaced brass gears with our glass-filled nylon gears in a water pump – they lasted 3x longer and cost 70% less!

Q: Can nylon gears operate in high-temperature environments?

A: Absolutely, but you need to choose the right grade:

- Standard nylon (PA66): Reliable up to 100°C continuous use

- Heat-stabilized grades (PA46): Work at 150°C continuous

- Above 150°C: You’ll need specialty polymers like PEEK or PPS

Critical Note: Above 150°C, nylon starts to soften and lose strength – don’t push it!

Q: Are custom nylon gears cost-effective?

A: Hell yeah, they are! Let me break it down for you:

- High volume (10k+): Injection molding tooling costs are offset by low material and production costs

- Small batches: CNC machining avoids tooling expenses entirely

- Total cost of ownership: Longer service life and low maintenance make them very cost-effective

Cost Comparison: Nylon gears typically cost 30-70% less than equivalent metal gears, and last longer in many applications!

Q: Do nylon gears require lubrication?

A: This is one of my favorite things about nylon – usually, no!

- Most applications: No external lubrication needed due to self-lubricating properties

- High-speed or heavy-load: Occasional light oiling can extend life, but avoid strong solvents

- Food applications: No lubricant needed at all – perfect for FDA compliance

Bonus: No lubricant means no contamination, less maintenance, and cleaner operation!

Q: How do I specify custom nylon gears for my application?

A: Glad you asked! Here’s what we need to know:

Design Specs:

- Tooth count and pitch

- Module or diametral pitch

- Bore size and tolerance

- Face width

Operating Conditions:

- Torque and speed requirements

- Temperature range

- Environmental factors

- Load type (constant vs variable)

Material Preferences:

- Nylon type (PA6, PA66, etc.)

- Fillers or reinforcements

- Color requirements

- Special properties needed

Ready to Upgrade Your Gears?

Whether you need low-noise gears for medical devices, corrosion-resistant parts for food processing, or lightweight components for robotics, we can deliver precision-engineered nylon gear solutions that fit your exact needs.

Share your application details – load requirements, dimensions, environmental conditions – and our team will provide material recommendations, design insights, and cost estimates. Let’s create nylon gears that perfectly match your needs!

Get Your Custom Nylon Gears Today!

Contact our engineering team for a free consultation and quote: