In the world of manufacturing, creating strong, reliable connections in plastic components is essential for product performance and longevity. Customized plastic molding threaded inserts provide an innovative solution to this challenge, offering superior fastening capabilities compared to traditional methods. Whether you’re designing electronic devices, automotive components, or consumer products, understanding how these specialized inserts work and their benefits can significantly enhance your product design and manufacturing process.

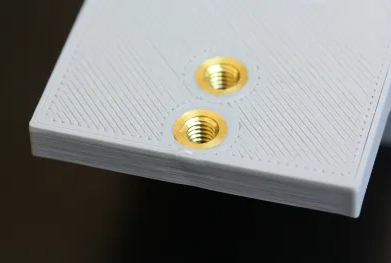

Self-tapping brass threaded insert designed for thermoplastics and thermosetting materials

What Are Customized Plastic Molding Threaded Inserts?

Customized plastic molding threaded inserts are specialized metal components designed to be integrated into plastic parts during the injection molding process. These inserts create strong, durable threads within plastic components, allowing for secure fastening using screws or bolts. Unlike direct threading of plastic, which can strip easily under stress, threaded inserts provide metal-to-metal connections that withstand repeated assembly and disassembly.

How Threaded Inserts Work in Plastic Molding

The process involves placing the threaded insert into the mold cavity before the plastic is injected. As molten plastic flows around the insert, it forms a tight bond with the insert’s knurled or textured exterior. This creates a mechanical lock that prevents the insert from rotating or pulling out under torque or axial loads.

Types of Installation Methods

There are several techniques for installing threaded inserts in plastic components:

Molded-in Inserts: Placed in the mold before injection, offering the strongest bond

Heat Insertion: Inserted using heat to soften the plastic and create a secure fit

Ultrasonic Insertion: Uses ultrasonic vibrations to soften plastic and install the insert

Press-in Inserts: Cold-pressed into pre-drilled holes in the plastic component

Self-tapping Inserts: Cut their own threads as they are screwed into the plastic

Customized plastic injection molding solution showing sensor housing with integrated threaded inserts

Advantages of Customized Plastic Molding Threaded Inserts

Superior Strength and Durability

Customized plastic molding threaded inserts provide significant advantages over traditional fastening methods:

- Metal-to-Metal Connections: Eliminate the risk of thread stripping in plastic

- High Pull-Out Resistance: Knurled or textured surfaces create mechanical locks

- Repeated Assembly: Withstand multiple assembly and disassembly cycles

- Temperature Stability: Maintain performance across a wide temperature range

Precision Engineering and Customization

One of the key benefits of these inserts is their ability to be customized to specific requirements:

- Precise Thread Sizes: Available in metric and imperial sizes from M1 to M12 and beyond

- Custom Dimensions: Tailored lengths, diameters, and flange configurations

- Material Selection: Brass, stainless steel, aluminum, and other specialized alloys

- Surface Treatments: Zinc plating, nickel plating, or passivation for corrosion resistance

Cost-Effective Manufacturing

While the initial investment in customized inserts may be higher than standard fasteners, the long-term benefits justify the cost:

- Reduced Assembly Time: Simplify production with integrated fastening solutions

- Lower Rejection Rates: Eliminate thread stripping and assembly errors

- Longer Product Life: Enhanced durability reduces warranty claims and replacements

- Design Flexibility: Enable complex designs that would be impossible with traditional methods

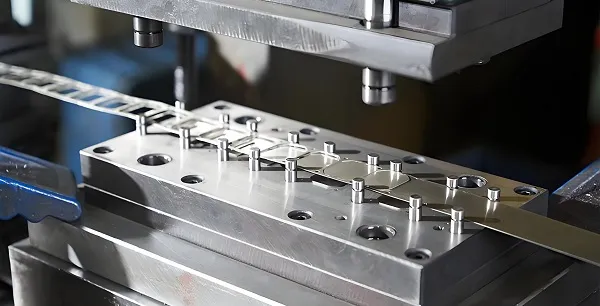

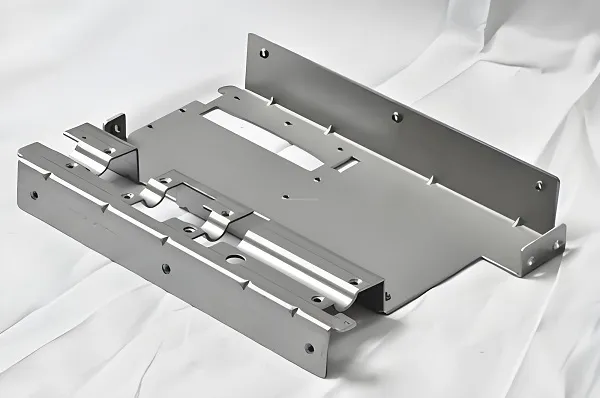

Worker inserting components into an injection molding machine for insert molding process

Applications of Customized Plastic Molding Threaded Inserts

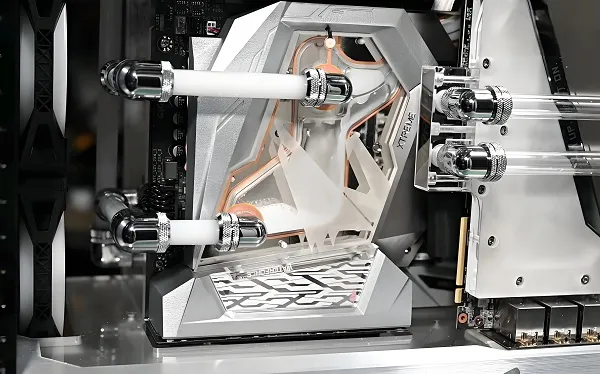

Electronics and Technology

In the electronics industry, precision and reliability are paramount. Threaded inserts are used in:

- Smartphone and Tablet Cases: Providing secure mounting points for internal components

- Computer Components: Hard drive mounts, motherboard standoffs, and heat sink attachments

- Consumer Electronics: Camera housings, speaker enclosures, and control panels

- Medical Devices: Surgical instruments, diagnostic equipment, and wearable technology

Automotive Industry

Automotive applications demand high performance under extreme conditions:

- Interior Components: Dashboard mounts, seat attachments, and trim pieces

- Exterior Parts: Light housings, bumper components, and mirror assemblies

- Engine Bay: Sensor mounts, electrical connectors, and fluid reservoirs

- Chassis and Body: Structural components and decorative elements

Household Appliances

Appliance manufacturers rely on threaded inserts for:

- Kitchen Appliances: Blender bases, mixer attachments, and control panels

- Laundry Equipment: Washing machine components, dryer parts, and detergent dispensers

- Heating and Cooling: HVAC components, thermostat housings, and fan assemblies

- Small Appliances: Coffee makers, toasters, and vacuum cleaner parts

Industrial Equipment

Heavy-duty industrial applications benefit from the strength of threaded inserts:

- Machinery Components: Gearboxes, pump housings, and motor mounts

- Construction Equipment: Control panels, sensor housings, and hydraulic components

- Agricultural Machinery: Harvester parts, irrigation systems, and tractor components

- Aerospace: Lightweight, high-strength solutions for aircraft interiors and exteriors

Precision M3 brass threaded insert with knurled exterior for secure plastic molding applications

The Customization Process: From Design to Delivery

Step 1: Design Consultation

The process begins with a thorough understanding of your specific requirements:

- Application Analysis: Understanding how the insert will be used and the loads it will 承受

- Material Selection: Choosing the right material based on environmental conditions and strength requirements

- Design Optimization: Engineering the insert for optimal performance and manufacturability

- Cost Analysis: Providing competitive pricing for custom designs and production volumes

Step 2: Prototyping and Testing

Before full production, prototypes are created and tested:

- Rapid Prototyping: Using CNC machining to create functional prototypes

- Performance Testing: Evaluating pull-out strength, torque resistance, and durability

- Material Compatibility: Testing with your specific plastic material

- Design Refinement: Making adjustments based on test results and feedback

Step 3: Tooling and Production

Once the design is approved, production tooling is created:

- Tool Design: Engineering precision dies for insert manufacturing

- Production Setup: Configuring equipment for high-volume production

- Quality Control: Implementing rigorous inspection processes at every stage

- Volume Production: Scaling production to meet your manufacturing needs

Step 4: Delivery and Support

The final stage ensures seamless integration into your manufacturing process:

- Just-in-Time Delivery: Coordinating delivery schedules with your production timeline

- Technical Support: Providing installation guidance and process optimization

- Continuous Improvement: Monitoring performance and making refinements as needed

- After-Sales Service: Offering ongoing support and troubleshooting assistance

Brass knurl molding insert designed for secure integration into plastic components

Frequently Asked Questions About Customized Plastic Molding Threaded Inserts

Can threaded inserts be used in all types of plastics?

While threaded inserts work with most thermoplastics and thermosets, some materials require special consideration:

- Soft Plastics: LDPE, HDPE, and PP may require different insert designs

- Glass-Filled Plastics: Reinforced materials need inserts with higher pull-out resistance

- High-Temperature Plastics: PEEK, PPS, and LCP require inserts that can withstand elevated temperatures

- Biodegradable Plastics: Special formulations may require modified insert designs

What materials are available for customized threaded inserts?

The choice of material depends on the application requirements:

- Brass: Most common, offering good strength and corrosion resistance

- Stainless Steel: Ideal for corrosive environments and high-temperature applications

- Aluminum: Lightweight option for weight-sensitive applications

- Steel: High-strength option for heavy-duty applications

- Special Alloys: Titanium, Inconel, and other exotic materials for specialized applications

How long does it take to produce custom inserts?

Production timelines vary based on complexity and volume:

- Prototyping: 1-2 weeks for CNC machined prototypes

- Tooling: 3-6 weeks for custom tooling development

- Production: 2-4 weeks for initial production runs

- Volume Production: 1-2 weeks for repeat orders

What design considerations are important for threaded inserts?

Key design factors include:

- Thread Size and Type: Choosing the appropriate thread standard (metric, UNC, UNF)

- Insert Geometry: Knurl pattern, flange design, and overall dimensions

- Material Compatibility: Ensuring compatibility with the plastic substrate

- Environmental Factors: Temperature, humidity, and chemical exposure

- Load Requirements: Understanding the expected torque and pull-out forces

Can inserts be customized for specific applications?

Yes, virtually every aspect of the insert can be customized:

- Custom Threads: Non-standard thread sizes and pitches

- Special Shapes: Unique geometries for specific mounting requirements

- Surface Treatments: Custom plating or coatings for specific environments

- Color Matching: Colored plating to match the plastic component

- Integrated Features: Combining multiple functions into a single insert

Why Choose Professional Customized Threaded Insert Services?

Expert Engineering Support

Partnering with an experienced manufacturer provides access to:

- Design Expertise: Engineers specializing in insert design and plastic molding

- Material Knowledge: Understanding of material compatibility and performance requirements

- Process Optimization: Maximizing production efficiency and product quality

- Cost Reduction: Identifying opportunities to reduce costs without sacrificing quality

Quality Assurance

Professional manufacturers implement rigorous quality control processes:

- Certifications: ISO 9001, ISO 13485, and IATF 16949 certifications

- Testing Protocols: Comprehensive performance and durability testing

- Traceability: Complete documentation of materials and processes

- Continuous Improvement: Ongoing quality monitoring and process refinement

Scalability and Flexibility

Professional services offer the flexibility to meet changing needs:

- Volume Flexibility: From prototype quantities to millions of parts

- Design Changes: Ability to quickly implement design modifications

- Global Sourcing: Access to global manufacturing capabilities

- Supply Chain Management: Ensuring reliable delivery and inventory management

Get Started with Your Custom Threaded Insert Project Today

Ready to enhance your product design with customized plastic molding threaded inserts? Here’s how to begin:

1. Define Your Requirements

- Application Details: How the insert will be used and the environment it will operate in

- Performance Specifications: Expected loads, temperatures, and durability requirements

- Material Preferences: Plastic type and any specific insert material requirements

- Production Volume: Expected quantities for prototyping and production

2. Design and Engineering

- CAD Design: Provide 3D models or detailed drawings of your requirements

- Design Review: Our engineers will review your design and suggest optimizations

- Prototype Development: Create functional prototypes for testing and validation

- Design Approval: Finalize the design before moving to production

3. Production Planning

- Material Selection: Choose the optimal material for your application

- Tooling Development: Create precision tooling for high-quality production

- Process Optimization: Develop the most efficient manufacturing process

- Quality Control: Establish quality standards and inspection processes

4. Production and Delivery

- Volume Production: Manufacture inserts to your specifications

- Quality Inspection: Rigorous testing and inspection of all products

- On-Time Delivery: Ensure timely delivery to meet your production schedule

- Technical Support: Provide ongoing support and troubleshooting assistance

Customized plastic molding threaded inserts offer a versatile, reliable solution for creating strong, durable connections in plastic components. By partnering with an experienced manufacturer, you can leverage the latest design and manufacturing technologies to enhance your product performance and reduce production costs.

Contact us today to discuss your specific requirements and discover how customized threaded inserts can transform your product design and manufacturing process.

This article was created to provide comprehensive information about customized plastic molding threaded inserts. For more specific details or to request a quote for your project, please contact our technical sales team.