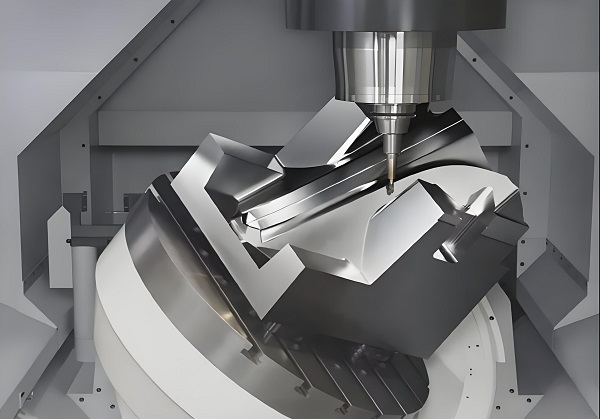

Pocket CNC 5-axis machine tools refer to the integration of five axes, including three linear axes (X, Y, Z) and two rotary axes (usually A and B axes or A and C axes) on a single machine tool, which is capable of simultaneous machining in multiple directions and realizes efficient, high-precision manufacturing of complex parts. This type of machine is usually relatively small in size, but powerful enough for precision machining in limited space.

1. Pocket CNC 5-axis parts production process

Part design and programming

Design: First, according to customer needs or product design requirements, use CAD (Computer Aided Design) software to draw a three-dimensional model of the part. This step is the basis for subsequent processing, need to ensure the accuracy and rationality of the design.

Programming: the use of CAM (Computer Aided Manufacturing) software, the CAD model is converted into a machine tool can be recognized by the machining program. The programming process requires the setting of tool paths, cutting parameters, machining sequence, etc., to ensure the accuracy and efficiency of the machining of parts.

Machine preparation and debugging

Machine inspection: Before machining, the pocket CNC 5-axis machine tool is thoroughly inspected, including the motion accuracy of each axis, the stability of the tool clamping system, and the normal operation of the cooling and lubrication system.

Tool selection and installation: select the appropriate tool according to the part material and machining requirements, and correctly installed in the tool magazine of the machine tool.

Workpiece clamping: fix the parts to be machined on the machine tool table to ensure firm clamping and accurate positioning.

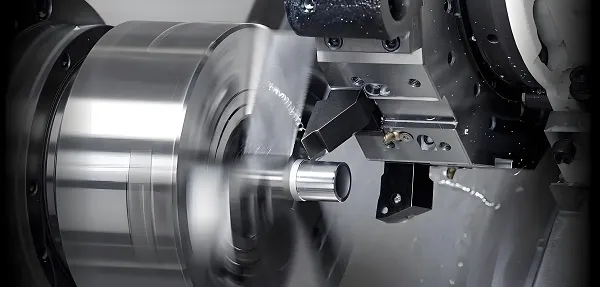

Machining process

Program loading and verification: Load the programmed machining program into the CNC system of the machine tool and carry out program verification to ensure that there is no error and then start machining.

Five-axis linkage machining: according to the program instructions, the machine tool will carry out multi-face and multi-directional machining of the parts under the linkage of three linear axes (X, Y, Z) and two rotary axes (A, B or A, C). During machining, the machine automatically adjusts the position and attitude of the tool and the workpiece to realize the machining of complex shapes and features.

Monitoring and Adjustment: During the machining process, the operator needs to closely monitor the running status of the machine tool and the machining quality, and find and deal with abnormal situations in time. If necessary, the machining parameters need to be adjusted to optimize the machining results.

Machining completion and inspection

Parts off the machine: After machining is completed, the parts are removed from the machine and initially cleaned.

Quality Inspection: Use measuring tools (such as coordinate measuring machine, projector, etc.) to inspect the quality of the parts to ensure that the dimensions and tolerances are in accordance with the design requirements.

Subsequent processing: carry out subsequent processing on the parts as required, such as deburring, cleaning, heat treatment, etc.

Packaging and delivery

Packing: the parts that have passed the inspection will be properly packed to prevent damage during transportation and storage.

Delivery: Deliver the parts to the customers according to the time and way agreed in the contract.

2.Pocket CNC 5-axis technical characteristics

High precision: Pocket CNC 5-axis machine tools adopt advanced CNC systems and motion control algorithms, which are capable of realizing micron-level or even higher precision machining. For example, the accuracy of some models of pocket 5-axis machines can reach 0.005mm to meet the needs of high-precision manufacturing.

High flexibility: With five coordinate axes, the machine tool can automatically adjust the position and attitude of the tool and workpiece during machining to realize multi-face and multi-directional machining. This flexibility enables the machine tool to machine a variety of complex shaped parts, such as curved surfaces and hole systems.

High efficiency: Through five-axis linkage machining, the machine tool can complete the machining of multiple surfaces in one clamping, which reduces the number of workpiece clamping times and auxiliary time, and improves the machining efficiency. At the same time, 5-axis machining can also avoid tool interference and overcutting phenomenon, further improving machining quality.

Wide range of applications: Pocket CNC 5-axis machine tools have a wide range of applications in aerospace, medical equipment, precision molds and other fields. These fields require high precision, surface quality and machining efficiency of parts, and 5-axis machine tools are able to meet these needs.

3. Pocket CNC 5-axis parts application areas

Aerospace

High-precision requirements: Aerospace equipment requires high precision and performance of parts, 5-axis machining technology can meet these requirements, to realize the accurate machining of complex surfaces and micro-structures.

Complex parts: Aircraft components, engine parts, etc. often have complex curved surfaces and internal structures, and 5-axis machining is able to move the tool freely in multiple directions to handle these complex shapes.

Lightweight design: The aerospace industry is pursuing lightweight design, and 5-axis machining can help achieve this goal by precisely controlling the amount of material removed.

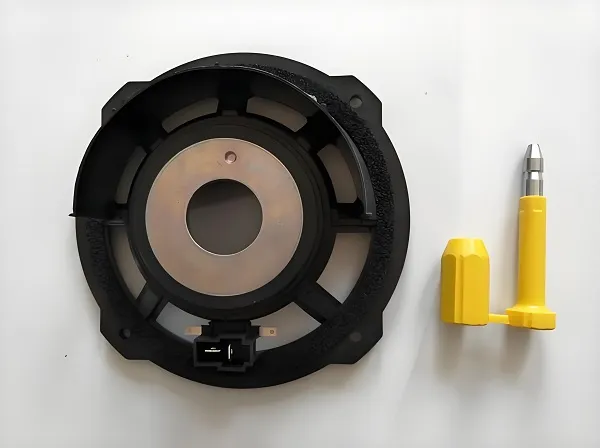

Automotive

Body and interior components: Automotive bodies and interiors often contain complex curved surfaces and shapes, and 5-axis machining can be used to efficiently machine these components.

Powertrain components: Engine blocks, crankshafts, and other powertrain components also require high-precision machining, and 5-axis machining technology can provide stable machining accuracy and efficiency.

Lightweight material processing: with the intensification of the trend of automobile lightweight, aluminum alloy, magnesium alloy and other lightweight materials are more and more widely used, five-axis machining technology can be adapted to the processing needs of these materials.

Medical equipment field

High-precision parts: medical devices require extremely high precision and quality of parts, 5-axis machining technology can realize precise machining of tiny parts to meet the manufacturing needs of medical devices.

Complex structure parts: such as endoscopes, surgical instruments, etc. These parts usually have complex shapes and structures, and 5-axis machining is capable of performing these processing tasks.

Mold Manufacturing Field

Complex mold structure: mold is an indispensable tool in industrial production, its cavity, core and other structures often have complexity, five-axis machining technology can achieve accurate processing of these complex structures.

Improvement of mold life: Improvement of mold accuracy and surface quality through 5-axis machining helps to extend the life of the mold.

Precision Instrument Field

High-precision processing: precision instruments require extremely high precision and performance of parts, 5-axis machining technology can realize precise processing and assembly of tiny parts, and improve the precision and stability of instruments.

Complex structure processing: such as optical instruments, precision measuring instruments, etc., these instruments often contain complex internal structure, 5-axis machining can be competent for the processing of these parts.

CNC 5-axis part customization FAQ

What is CNC 5-axis part customization?

CNC 5-axis part customization refers to the use of CNC 5-axis machines to provide high-precision, highly flexible machining services based on the specific needs of the customer. This customized service is capable of machining parts with complex shapes and high precision requirements, and is widely used in aerospace, medical equipment, precision molds, and other fields.

What are the advantages of CNC 5-axis parts customization?

High precision: CNC 5-axis machines are capable of micron-level or even higher precision machining to meet the demands of high-precision manufacturing.

High flexibility: 5-axis linkage machining can automatically adjust the position and attitude of the tool and workpiece to realize multi-face and multi-directional machining, which is suitable for machining complex shaped parts.

High efficiency: one clamping completes the machining of multiple faces, reducing the number of clamping times and auxiliary time, and improving the machining efficiency.

Customized service: personalized design and machining according to customer needs to meet the needs of specific application scenarios.

How to customize CNC 5-axis parts?

Demand communication: Customers and service providers conduct preliminary communication to clarify the specific requirements of the parts, materials, quantities and other information.

Design Confirmation: The service provider carries out CAD design according to the customer’s requirements and confirms the design scheme with the customer.

Programming and Simulation: Use CAM software to program and carry out machining simulation to ensure the correctness of the program and machining effect.

Processing and production: Processing and production on CNC 5-axis machine tools, quality monitoring and adjustment during the process.

Quality inspection: carry out quality inspection on the finished parts to ensure that they meet the design requirements.

Delivery and after-sales service: deliver qualified parts to customers and provide after-sales service and technical support.

How to calculate the price of CNC 5-axis parts customization?

The price of customized CNC 5-axis parts is usually calculated according to the complexity of the parts, material cost, machining hours, batch size and other factors. The specific price needs to be determined after detailed communication with customers. Generally speaking, the service provider will provide quotation or contract to clarify the price, delivery period, payment method and other terms.

How long does it take to customize CNC 5-axis parts?

The time for CNC 5-axis parts customization depends on a number of factors, including the complexity of the part, the difficulty of machining, and the scheduling situation of the machine tool. Generally, the service provider will evaluate the customer’s specific needs and give a reasonable lead time. In case of emergency, the service provider may provide expedited service, but additional expediting fee is required.

How to ensure the quality of customized CNC 5-axis parts?

Strict quality control system: the service provider should set up a perfect quality control system to monitor and test the whole machining process.

Advanced processing equipment: adopting high-precision and high-stability CNC 5-axis machine tools for processing to ensure processing accuracy and stability.

Professional technicians: We have a team of experienced technicians and engineers who are capable of dealing with various complex processing problems.

Customer acceptance: after processing is completed, customers are invited to acceptance to ensure that the parts meet the design requirements and quality standards.

What are the considerations for customizing CNC 5-axis parts?

Clarify the requirements: Customers need to clarify the specific requirements of the parts, materials, quantities and other information before customization to avoid miscommunication leading to processing errors.

Choose a reliable service provider: choose a service provider with rich experience and good reputation for cooperation to ensure the processing quality and delivery time.

Reasonable budget: according to the complexity of the parts and processing requirements reasonable budget costs, to avoid exceeding the budget range.

Timely communication: Keep timely communication with the service provider during the machining process to understand the progress and quality of machining and solve problems in time.