Precision titanium machined parts are high-performance parts precisely cut or shaped from titanium alloy raw materials using advanced machining technology. Titanium alloys are widely used in aerospace, medical devices, marine engineering, chemical industry and other fields due to their high strength, low density, good corrosion resistance and biocompatibility. Customized precision titanium machined parts can meet the strict requirements of material properties, dimensional accuracy and surface quality in specific application scenarios.

1.Precision titanium machining production process

Raw material selection and inspection: According to the customer’s needs and the application environment of the parts, select suitable titanium alloy raw materials, such as TA1, TA2, TC4, etc., and carry out strict chemical composition and mechanical properties inspection.

Drawing analysis and process design: Receive and analyze the drawings and technical requirements provided by customers to determine the machining process, including cutting parameters, tooling and fixture design, etc., to ensure machining accuracy and efficiency.

Blank preparation: Process titanium alloy raw materials into blanks close to the final shape of the parts by forging, rolling or casting to reduce the amount of subsequent machining.

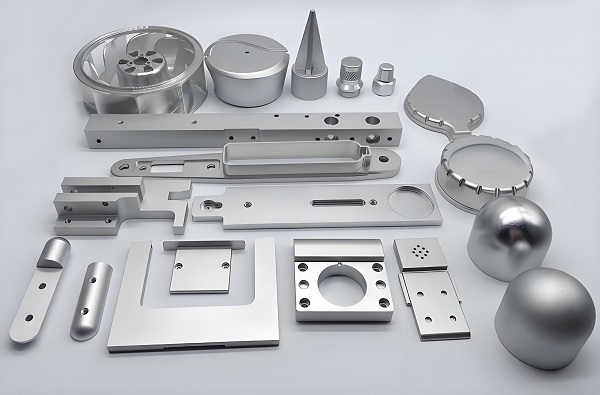

Precision machining: High-precision CNC machine tools (e.g. CNC lathe, milling machine, grinder, etc.) are used to carry out precision machining, including turning, milling, drilling, grinding and other processes, in order to achieve the dimensional accuracy and surface quality required by the drawings.

Heat treatment and surface treatment: According to the performance requirements of the parts, carry out heat treatment processes such as annealing, solution treatment, aging treatment, etc., as well as surface treatment processes such as sandblasting, polishing, anodizing, etc., in order to improve the mechanical properties and corrosion resistance of the parts.

Quality Inspection and Acceptance: Using high-precision inspection equipment such as CMM and non-destructive testing equipment, we carry out comprehensive inspection on the processed parts to ensure that they meet the design requirements and quality standards.

Packaging and Delivery: Clean and rust-proof the qualified parts, and package and deliver them according to customers’ requirements.

2.Customized precision titanium machining parts

Demand communication: Communicate with customers in depth to understand the specific use, performance requirements, quantity of parts, etc., in order to customize the design.

Program design and evaluation: according to the customer’s needs, develop a detailed processing program and process flow, including material selection, processing methods, heat treatment process, etc., and technical evaluation to ensure the feasibility and economy of the program.

Sample production and validation: produce sample parts, conduct performance testing and validation to ensure that customer requirements are met.

Mass production: After the customer confirms the samples, mass production is carried out to ensure that the quality and performance of each batch of parts are consistent.

After-sales service: Provide comprehensive after-sales service, including technical support, quality problem solving and parts supply.

3.Precision titanium machining parts material

Material:

TA1: pure titanium, with good plasticity and toughness, suitable for occasions with low requirements for strength.

TA2: low-alloyed titanium, slightly higher strength than TA1, suitable for occasions with high requirements for corrosion resistance.

TC4: α+β type titanium alloy, high strength, good toughness, excellent corrosion resistance, widely used in aerospace, medical equipment and other fields.

Characteristics:

High strength: titanium alloy has high tensile strength and yield strength, able to withstand larger loads.

Low density: The density of titanium alloy is about 50% of steel, which helps to reduce the weight of parts.

Good corrosion resistance: Titanium alloys exhibit excellent corrosion resistance in a wide range of corrosive media.

Excellent biocompatibility: titanium alloy has good compatibility with human tissue and is widely used in medical devices.

4. Precision titanium machined parts characteristics of different materials

Product:

TA1 precision titanium machined parts: suitable for decorative parts and structural parts that do not require high strength.

TA2 precision titanium machined parts: suitable for chemical equipment, marine engineering parts, etc., which have high requirements for corrosion resistance.

TC4 precision titanium machined parts: suitable for structural parts in aerospace field, implants in medical devices, etc.

Data:

TA1: tensile strength ≥240MPa, yield strength ≥180MPa, density about 4.5g/cm³.

TA2: Tensile strength ≥280MPa, yield strength ≥240MPa, density about 4.5g/cm³.

TC4: tensile strength ≥895MPa, yield strength ≥825MPa, density about 4.43g/cm³, with good fatigue resistance and fracture toughness.

Customized precision titanium machined parts FAQ

Q1: How much precision can be achieved for precision titanium machined parts?

A: The accuracy of our precision titanium machined parts can reach ±0.01mm or even higher, depending on the size and shape of the part.

Q2: What are the main advantages of titanium alloys?

A: Titanium alloys are characterized by high strength, low density, good corrosion resistance and biocompatibility, and are suitable for a variety of demanding application scenarios.

Q3: How do you ensure the quality of precision titanium machined parts?

A: We use advanced processing technology and high-precision testing equipment to conduct comprehensive testing of parts to ensure that dimensional accuracy, surface quality and mechanical properties are in line with customer requirements.

Q4: How long does it take to customize precision titanium machined parts?

A: The production cycle mainly depends on the complexity, quantity and material preparation of the parts, usually within 7-15 working days to complete the sample production, mass production time depends on the specific needs.

Q5: How can I get a quote for precision titanium machined parts?

A: Please provide the drawing or technical requirements of the parts, we will make a detailed quotation and process planning according to your needs.