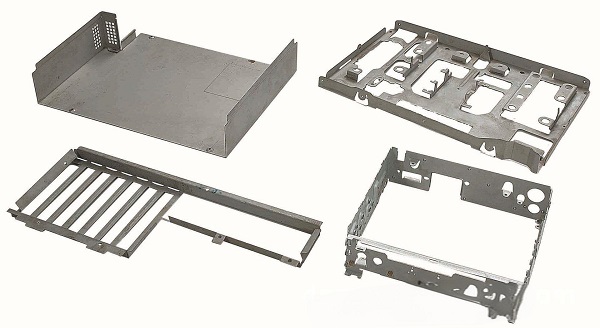

Prototype sheet metal stampings are an integral part of the manufacturing industry, where they are manufactured by the stamping process from sheet metal into parts with specific shapes and sizes. These parts are widely used in many fields such as automotive, electronics, aerospace, medical devices, etc., and are the basic components of complex products and equipments.

1.Prototype sheet metal stamping parts production process

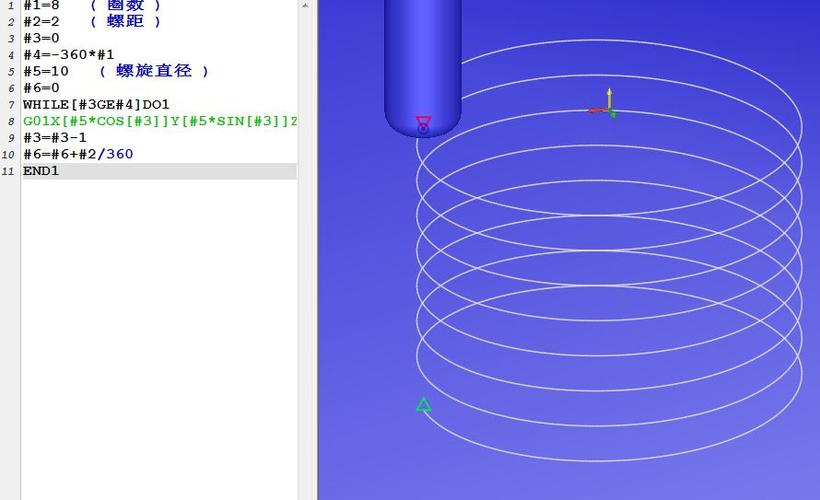

Design and Planning: According to customer requirements, use CAD software to carry out 3D design of the parts and plan the stamping process path.

Material Preparation: According to the design requirements, select suitable metal sheets, such as stainless steel, aluminum alloy, copper, etc., and carry out cutting and pre-treatment.

Tooling design and manufacture: design and manufacture special stamping tooling according to the shape and size of the part.

Stamping and forming: Put the pre-treated metal sheet into the stamping machine, and make it form the required shape and size through the stamping action of the die.

Subsequent treatment: The press-formed parts are subjected to subsequent treatments such as deburring, cleaning, surface treatment, etc., in order to improve the quality and appearance of the parts.

Quality Inspection: Strict quality inspection of the finished products to ensure that the parts meet the design requirements and customer expectations.

2.Customized prototype sheet metal stamping parts

Individualized design: Provide individualized part design service according to the specific needs of customers to meet their special requirements.

Material selection: Provide a variety of sheet metal for customers to choose from, including stainless steel, aluminum alloy, copper, etc. to meet the needs of different application scenarios.

Process Optimization: Optimize the stamping process according to the shape, size and material properties of the part to improve productivity and part quality.

Rapid Response: Provide fast response and efficient customization services to ensure customers can get the parts they need on time.

3.Introduction of prototype sheet metal stamping parts

Material:

Stainless steel: good corrosion resistance and strength, suitable for many harsh environments.

Aluminum alloy: lightweight, high strength, good corrosion resistance, widely used in aerospace and automotive fields.

Copper: good conductivity, corrosion resistance, easy processing, suitable for electronic and electrical fields.

Characteristics:

High precision: the size and shape accuracy of the parts can be ensured by the precision stamping process.

High strength: after stamping and molding, the metal sheet has high strength and stiffness and can withstand large loads.

Good surface quality: after subsequent treatment, the surface of the parts is flat and smooth, with good appearance quality.

Strong customizability: it can be personalized and customized according to the specific needs of customers.

4. Characteristics of prototype sheet metal stamping parts of different materials

Products: stainless steel stamping parts, aluminum alloy stamping parts, copper stamping parts, etc.

Data:

Stainless steel stamping parts: strong corrosion resistance, tensile strength ≥500MPa, hardness HB≥187.

Aluminum alloy stamping parts: low density (about 2.7g/cm³), tensile strength ≥200MPa, good thermal and electrical conductivity.

Copper stamping: electrical conductivity ≥98% IACS, tensile strength ≥220MPa, good corrosion resistance, easy to weld and process.

Customized Prototype Sheet Metal Stamping Parts FAQ

Q1: How to determine the required material for the stamping parts?

A: When choosing the material for stamped parts, you need to consider the environment in which the parts are to be used, load bearing requirements, corrosion resistance and cost. Stainless steel is suitable for harsh environments and occasions requiring high strength and corrosion resistance; aluminum alloy is suitable for occasions requiring light weight, high strength and good thermal conductivity; copper is suitable for occasions requiring high electrical conductivity and corrosion resistance.

Q2: How to ensure the precision of stamped parts?

A: The precision of stamped parts is mainly ensured through mold design and manufacturing precision, control of stamping process parameters and subsequent treatment processes. We adopt advanced mold design and manufacturing technology, as well as precise stamping equipment and process parameter control to ensure the size and shape accuracy of stamped parts.

Q3: What is the lead time for stamped parts?

A: The lead time depends on factors such as the complexity and quantity of the parts and the capacity of the production equipment. Generally speaking, simple stamped parts can be produced and delivered in a shorter time; while complex stamped parts may require longer production and commissioning time. We will provide accurate delivery time according to customers’ specific needs and orders.

Q4: How to calculate the price of stamping parts?

A: The price of stamped parts mainly depends on factors such as material costs, mold design and manufacturing costs, production man-hours and follow-up processing costs. We will provide detailed quotation and costing according to customers’ specific needs and order quantity.