PVC (polyvinyl chloride) globe valve is a kind of fluid control equipment widely used in chemical industry, water treatment, agricultural irrigation and other fields. It is made of PVC material, with the advantages of light weight, corrosion resistance, low price, etc. It is suitable for the control of a variety of corrosive media.PVC Globe Valve controls the opening and closing of the valve by rotating the valve stem, so as to achieve the purpose of regulating the flow.

1.PVC globe valve production process

Material Preparation: Choose high-quality PVC resin, according to product specifications and performance requirements, add the appropriate amount of plasticizers, stabilizers and other auxiliary materials, mix well and then sent to the extruder.

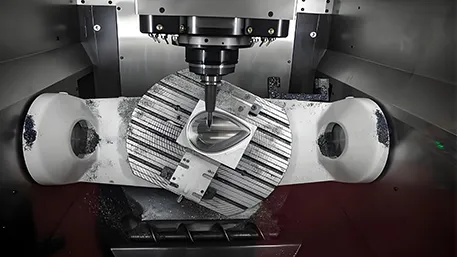

Extrusion molding: the mixed PVC material is heated and melted through the extruder, and extruded into the preliminary shape of the valve body, valve cover and other parts.

Cooling and shaping: The extruded parts are quickly cooled by the cooling water tank and shaped into the required shape and size.

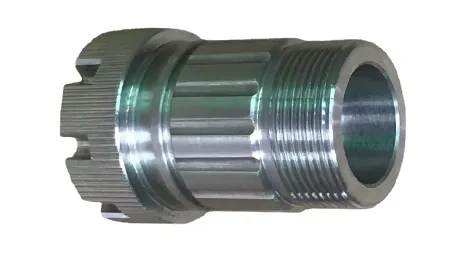

Processing and assembly: The cooled parts are cut and trimmed, and then assembled with components such as valve stem, valve seat and seals to form a complete PVC globe valve.

Quality Inspection: Conduct pressure test, sealing test and other quality inspection on the finished products to ensure that the products meet the relevant standards and customer requirements.

Packing and shipping: The qualified products will be packed, labeled with product information, and then shipped according to customer requirements.

2.Customized PVC Globe Valve

Customer demand communication: communicate with customers to understand their specific needs, including the valve’s working pressure, flow, media, installation environment, etc..

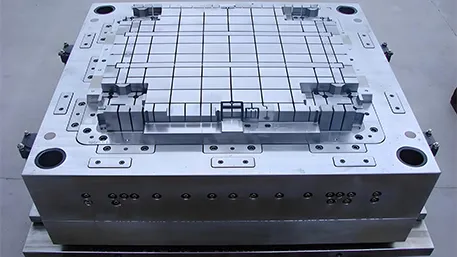

Design program development: according to customer demand, combined with the design principle of PVC globe valve and material properties, to develop a detailed design program, including the structure of the valve, size, connection, etc..

Material selection and procurement: according to the design program, select PVC materials that meet the requirements and purchase them. At the same time, ensure that the purchased materials are of reliable quality and meet the production requirements.

Production and processing: According to the design scheme and production flow, process, mold and assemble PVC materials to produce customized PVC globe valves that meet customers’ requirements.

Quality testing and acceptance: Strict quality testing is carried out on the customized products, including pressure test, sealing test, etc., to ensure that the products are stable, safe and reliable. Then, customers are invited for acceptance to ensure that the products meet their requirements.

3.PVC Globe Valve Material Introduction

Material: PVC (polyvinyl chloride)

Characteristics:

Corrosion resistance: PVC material has good corrosion resistance to many kinds of acid, alkali, salt and other corrosive media, and is suitable for the control of many kinds of corrosive media.

Light weight: PVC material density is small, making the PVC globe valve has the advantages of light weight, easy to install and transport.

Low price: PVC material prices are relatively low, making the cost of PVC globe valve is low, has a high cost-effective.

Easy to process: PVC material is easy to process molding, can meet the needs of different shapes and sizes, easy to customize production.

4. Different performance PVC globe valve characteristics

Ordinary PVC globe valve: working pressure ≤ 1.0MPa, applicable temperature range -5 ℃ ~ 60 ℃, strong corrosion resistance, but limited high temperature resistance.

Modified PVC globe valve: by adding special additives to improve the high temperature resistance of PVC materials and mechanical strength, working pressure up to 1.6MPa, the applicable temperature range expanded to -10 ℃ ~ 80 ℃.

Reinforced PVC globe valve: adopting reinforced PVC material, through special process, the valve has higher strength and wear resistance, applicable to more severe working environment. The working pressure can be up to 2.5MPa, and the applicable temperature range can be up to -20℃~100℃.

Other materials (such as PP, PE, etc.) globe valve: Although this article focuses on PVC globe valve, but other materials such as PP (polypropylene), PE (polyethylene), etc. also have their own characteristics and advantages. For example, PP globe valves have high temperature resistance and chemical stability; PE globe valves have excellent flexibility and low temperature resistance. However, these materials differ from PVC in terms of corrosion resistance, strength and price, and the specific choice needs to be weighed according to application scenarios and needs.

Customized PVC Globe Valves FAQ

Q1: What is the corrosion resistance of PVC globe valve?

A1:PVC material has good corrosion resistance to a variety of corrosive media, so PVC globe valve is widely used in chemical industry, water treatment and other fields. However, the specific corrosion resistance needs to be considered according to the type of media, concentration, temperature and other factors.

Q2:What is the working pressure and temperature range of PVC globe valve?

A2:The working pressure of ordinary PVC globe valve is generally not more than 1.0MPa, and the applicable temperature range is -5℃~60℃. However, through material modification and process improvement, PVC globe valves with higher working pressure and wider temperature range can be produced.

Q3:How to customize PVC globe valve to meet my needs?

A3:Customers can communicate with professional PVC globe valve manufacturers according to their needs. After clarifying the working pressure, flow rate, medium, installation environment and other specific requirements, the manufacturer will develop a detailed design program and produce customized PVC globe valves that meet customer requirements.