Right Angle Plastic Trim is a type of plastic product widely used in many industries, such as furniture, construction, automotive and electronics. They are usually used for decorating, protecting or connecting parts and are favored for their lightweight, high strength and easy processing. Right angle plastic trim can not only enhance the aesthetics of the product, but also enhance its durability and functionality.

1.Right-angle plastic trim production process

Raw material preparation: Choose plastic raw materials suitable for injection molding, such as polyethylene (PE), polypropylene (PP), ABS or polycarbonate (PC) and so on. These raw materials are processed to ensure that they are suitable for injection molding machines.

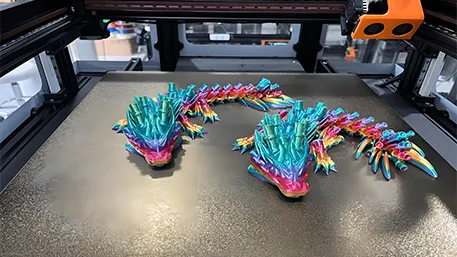

Injection molding: The processed plastic raw material powder or granules are put into the hopper of the injection molding machine. The injection molding machine heats up the raw material to melt it, and then the molten plastic is injected into the mold through an injection unit. The mold is customized to the shape and size of the right-angle plastic trim.

Cooling and Curing: The molten plastic injected into the mold by the injection molding machine is cooled and cured in the mold. The quality and speed of product curing is ensured by controlling the cooling time and temperature.

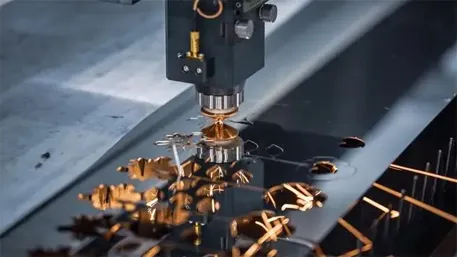

Trimming: After cooling and curing, right angle plastic trim products need to be trimmed. This is usually done by cutting or sanding to remove burrs or other irregularities in the mold so that the product meets the set size and appearance requirements.

Packaging: After trimming the right angle plastic trims are sorted, stacked and packaged. Usually use plastic bags, cartons or trays and other packaging methods to ensure the safety of the product in the process of transportation and storage.

2. Right angle plastic trim customization

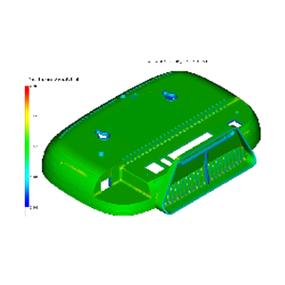

Design: According to the customer’s demand, the design of right angle plastic trims. The design includes the determination of shape, size, color, texture and other elements to ensure that the product meets the customer’s expectations.

Mould making: According to the design, make the mold for the right angle plastic trim. The precision and durability of the mold directly affects the quality and productivity of the product.

Raw Material Selection: According to the customer’s requirements and product usage, select the appropriate plastic raw material. Different raw materials have different physical and chemical properties, so the selection needs to consider the environment in which the product will be used.

Production: The selected raw materials are put into the injection molding machine and molded through the mold. Strict control of process parameters is required during the production process to ensure the quality and stability of the product.

Inspection and Packaging: The quality inspection of the produced right angle plastic trims is carried out to ensure that the products meet the design requirements. After passing the inspection, packaging and shipping.

3. Right Angle Plastic Trim Material Introduction

Material:

Polyethylene (PE)

Polypropylene (PP)

ABS

Polycarbonate (PC)

Characteristics:

Light weight and high strength: right angle plastic trim is light weight and high strength, easy to carry and install.

Resistant to acid and alkali corrosion: able to resist the erosion of acid, alkali, salt and other chemicals, suitable for use in chemical, pharmaceutical and other special occasions.

Good insulation: it is an insulating material, suitable for use in electronic and electrical equipment.

Easy processing: it can be processed by injection molding, blow molding, etc. to make products of various shapes and specifications.

4. Characteristics of right-angle plastic ornaments of different materials

| Product | Material | Density (g/cm³) | Tensile Strength (MPa) | Flexural Strength (MPa) | Heat Resistance Temperature (°C) |

|---|---|---|---|---|---|

| Right-Angle Edge Guard | PE | 0.92 | 20-30 | 10-20 | 80 |

| Right-Angle Bumper Strip | PP | 0.90 | 30-40 | 20-30 | 100 |

| Right-Angle Decorative Strip | ABS | 1.05 | 40-50 | 30-40 | 105 |

| Right-Angle Trim Strip | PC | 1.20 | 60-70 | 40-50 | 130 |

(Note: The above data is for reference only, the specific value may vary depending on the material batch, production process and other factors.)

Customized Right Angle Plastic Trims FAQ

Q1:What shapes and sizes can be customized for right angle plastic trim?

A1: The shapes and sizes of right angle plastic trims can be customized according to customers’ requirements. Common shapes include L-shape, T-shape, U-shape, etc., and sizes are determined according to specific application scenarios.

Q2:What are the common colors of Right Angle Plastic Trim?

A2: The colors of right angle plastic trims can be customized according to customer needs, and the common colors include white, black, gray, red, blue and so on.

Q3:What is the lead time of Right Angle Plastic Trim?

A3: The lead time depends on the complexity of the product, the production batch and customer demand. Generally, the lead time is 7-15 working days.

Q4:How to guarantee the quality of Right Angle Plastic Trim?

A4: The quality assurance of right angle plastic trims is mainly realized through raw material selection, mold making, production process control and quality inspection. We strictly follow the requirements of ISO quality management system for production and management to ensure stable and reliable product quality.