Stamping bearings are a kind of bearings manufactured by stamping process, which are characterized by high precision, high strength, high load carrying capacity and long life. They are widely used in automobile, machinery, electronics, aerospace and other fields to provide stable support and rotation function for various mechanical equipment.

1. Stamping bearing production process

Design and planning:

According to customer requirements and application scenarios, design the shape, size and performance parameters of the bearings.

Make detailed production plan and process flow to ensure production efficiency and product quality.

Material selection and preparation:

Select metal materials that meet the requirements, such as carbon steel, stainless steel, alloy steel and so on.

Pretreat the material, such as cutting, cleaning, annealing, etc., to improve the stampability and forming quality of the material.

Stamping and forming:

The pretreated material is put into the stamping mold, and the pressure is applied to the mold by the stamping machine to make the material undergo plastic deformation and form the basic shape of the bearing.

The stamped bearing is trimmed and deburred to improve its surface quality and precision.

Heat treatment and surface treatment:

Heat treatment, such as quenching and tempering, is carried out on stamped bearings to improve their hardness and wear resistance.

Surface treatment, such as spraying, plating, etc., is carried out to improve the corrosion resistance and aesthetics of the bearings.

Inspection and testing:

Carry out strict inspection and testing on the stamping bearings, including tests on dimensional accuracy, rotational flexibility, load carrying capacity, etc., to ensure that the products meet the design requirements.

2. Customization of stamping bearings

Customer demand analysis:

Communicate with customers to understand their actual needs and use scenarios, such as bearing size, shape, load carrying capacity, rotational speed and so on.

Design and simulation:

According to the customer’s requirements, design the detailed structure of the bearings and carry out simulation analysis using CAD/CAM software to ensure the rationality and reliability of the design.

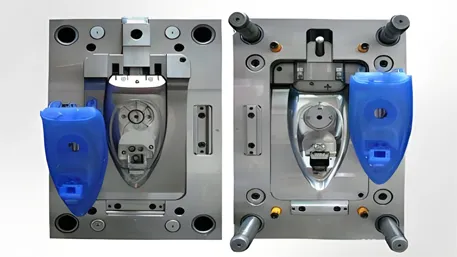

Mold design and manufacture:

According to the design drawings of the bearings, manufacture special stamping molds to ensure the precision and durability of the molds.

Mass production:

After successful commissioning of the mold, mass production is carried out to ensure production efficiency and product quality.

After-sales service:

Provide perfect after-sales service, including technical support, quality assurance and quick response, etc. to ensure customer satisfaction.

3. Introduction of stamping bearing materials

Material:

Carbon steel: with good strength and toughness, suitable for general mechanical applications.

Stainless steel: excellent corrosion resistance and high temperature resistance, suitable for applications in harsh environments.

Alloy steel: through the addition of alloying elements to improve the hardness and wear resistance of the material, suitable for high load bearing and high-speed running applications.

Characteristics:

High strength: able to withstand large radial and axial loads to ensure stable operation of mechanical equipment.

High precision: through precision stamping process and subsequent machining, the dimensional accuracy and rotational flexibility of the bearings are ensured.

Good wear resistance: the high surface hardness of the bearings after heat treatment can resist wear and fatigue damage.

Corrosion resistance: materials such as stainless steel and alloy steel have excellent corrosion resistance and can resist the erosion of corrosive media such as acid and alkali.

4. Characteristics of stamping bearings made of different materials

Products:

Carbon steel pressed bearings: suitable for general mechanical applications, such as transmission shafts, motor shafts, etc..

Stainless steel pressed bearings: suitable for applications in harsh environments, such as chemical equipment, food processing equipment.

Alloy steel stamped bearings: suitable for high load and high speed applications, such as machine tool spindles, wind turbines, etc.

Data:

| Material Type | Hardness (HBW) | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance |

|---|---|---|---|---|---|

| Carbon Steel | 180-220 | 400-600 | 240-400 | 7.85 | Moderate |

| Stainless Steel | 170-220 | 500-1000 | 200-800 | 7.93 | Excellent |

| Alloy Steel (42CrMo) | 220-280 | 800-1100 | 600-900 | 7.82 | Good |

Note: The above data are typical values, and the actual data may vary depending on factors such as specific materials, heat treatment processes and test conditions.

Customized Stamped Bearings FAQ

Q1: How long does it take to customize a stamping bearing?

A1: The customization time depends on the complexity of the bearing, the production process and customer requirements. Generally, it takes several weeks to several months from design to delivery.

Q2: How to guarantee the quality of customized stamping bearings?

A2: With advanced production equipment and technical team, we strictly follow the production process and quality control standards for operation and inspection to ensure the quality and performance of customized bearings.

Q3: How to calculate the price of customized stamping bearings?

A3: The price is calculated according to the shape, size, material and quantity of the bearings. We provide detailed quotation, customers can choose and confirm according to the quotation.

Through the above introduction, I believe you have a more comprehensive understanding of customized stamping bearings. If you have any questions or needs, please feel free to contact us, we will be happy to serve you.