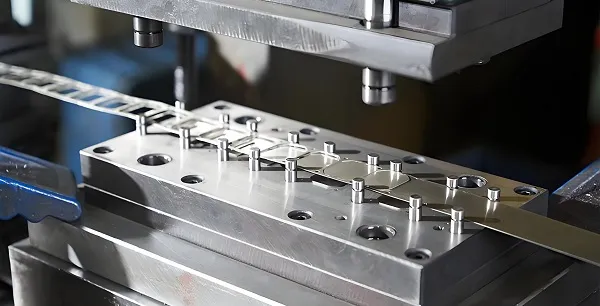

Stamping die parts refer to the various components used to manufacture stamping dies, which are combined and assembled to form a complete stamping die for processing metallic or non-metallic materials in a stamping press to produce plastic deformation or separation, so as to obtain parts of the required shape and size.

1. Stamping mold parts production process

Mold design drawings and related documents:

According to the customer’s requirements and product specifications, draw detailed mold design drawings, including the three-dimensional model of the mold, two-dimensional drawings and related technical documents.

Production preparation:

Prepare mold materials, such as alloy steel, high-speed steel, etc..

Prepare two types of tooling, mold common parts and standard parts.

Conduct NC program programming and calibration to ensure the accuracy of the machining process.

Rough machining:

Perform preliminary processing of raw materials, such as cutting, forging, etc., to form blank parts.

Scribing and drilling:

Scribe lines on the blank parts to determine the machining position and size, and then carry out drilling operations.

Roughing and semi-finishing:

Rough machining of rough parts is carried out by turning, milling and other processes to remove excess material and form the basic shape.

Then semi-finishing machining is carried out to further improve the dimensional accuracy and surface quality of the parts.

Heat Treatment:

Heat treatment such as quenching and tempering is performed on the parts to improve their hardness and wear resistance.

Finishing:

Through grinding, polishing and other processes, the parts are finish machined to ensure that their dimensional accuracy and surface roughness meet the requirements.

Mold assembly:

Assemble the parts to form a complete mold.

Debugging the mold to ensure that it can work normally.

Mold trial and calibration:

Use the mold to conduct a trial mold to check its performance and quality of the finished product.

According to the results of the trial mold, make necessary corrections and adjustments to the mold.

Acceptance into the warehouse, pick up and use:

Acceptance of qualified molds into the warehouse, waiting for customers to receive the use.

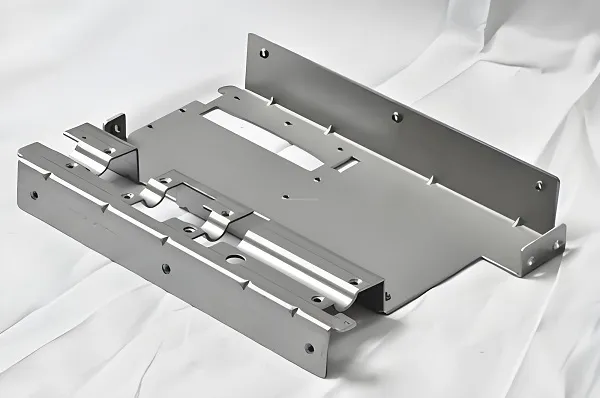

2. Customized stamping die parts

Customized demand:

According to the specific needs of customers, we can customize different shapes, sizes and structures of stamping die parts.

We can provide a full range of customized services from design, production to commissioning.

Customization process:

Customers put forward the customization requirements, including the shape, size, material and quantity of the parts.

We design the mold according to the customer’s demand, and provide the design plan and quotation.

After the customer confirms the design scheme and quotation, we carry out production preparation and rough machining.

According to the production flow, we gradually complete the rough machining, semi-finishing, heat treatment, finishing and other processes.

We carry out mold assembly and trial mold to ensure the performance of the mold and the quality of the finished product.

Finally, the qualified mold parts are delivered to customers.

Customized Advantage:

We can meet customers’ individual needs and provide customized solutions.

With advanced production equipment and technical team to ensure the quality and performance of customized parts.

Provide a full range of customized services, including design, production, commissioning, etc., saving time and energy for customers.

3. Introduction of stamping mold parts materials

Material:

Alloy steel: with high hardness, high strength and better wear resistance, thermal stability and other characteristics.

High-speed steel: with excellent cutting performance and wear resistance, suitable for high-speed stamping processing.

Cemented Carbide: Sintered from metal powders such as tungsten carbide and cobalt, with extremely high hardness and wear resistance.

Steel Junction Cemented Carbide: combines the advantages of steel and cemented carbide, with high hardness and toughness.

Characteristics:

High hardness: able to withstand large punching pressure and abrasion, ensuring the service life of the mold.

High strength: able to maintain the shape and dimensional stability of the mold under high pressure and high temperature environment.

Abrasion resistance: able to resist the friction and abrasion of the material in the stamping process, reducing the frequency of maintenance and replacement of the mold.

Thermal stability: under high temperature environment, it can keep the hardness and dimensional stability of the mold to avoid deformation and cracking.

4. Characteristics of stamping mold parts made of different materials

Products:

Alloy steel stamping die parts

High speed steel stamping die parts

Carbide stamping die parts

Steel bonded carbide stamping die parts

Note: The above data are typical values, the actual data may vary due to specific materials, heat treatment process and other factors.

Customized Stamping Die Parts FAQ

Q1: How long does it take to customize a stamping die part?

A1: The customization time depends on the complexity of the part, production process and customer requirements. Generally speaking, it can take anywhere from a few weeks to a few months from design to delivery.

Q2: How to ensure the quality of customized stamping die parts?

A2: We have advanced production equipment and technical teams that operate and inspect in strict accordance with production processes and quality control standards to ensure the quality and performance of our customized parts.

Q3: How to calculate the price of customized stamping die parts?

A3: The price is calculated according to the shape, size, material and quantity of the parts. We provide detailed quotation, customers can choose and confirm according to the quotation.

Through the above introduction, I believe you have a more comprehensive understanding of custom stamping die parts. If you have any questions or needs, please feel free to contact us, we will be happy to serve you.