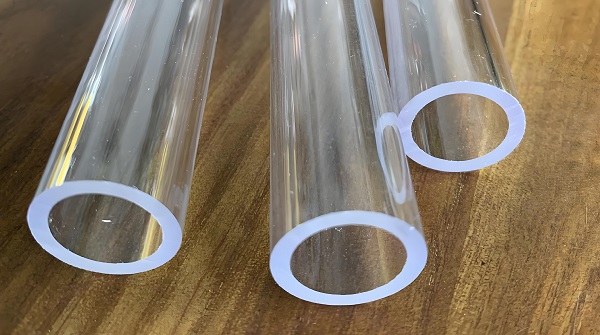

Transparent fuel hose is a piping material designed for fuel systems with high transparency, excellent fuel corrosion resistance and good flexibility. Its unique transparent characteristics allow users to visually monitor the fuel flow status, ensuring the safe and efficient operation of the fuel system. Transparent fuel hose is widely used in automobiles, motorcycles, ships, industrial machinery and fuel delivery systems.

1.Transparent fuel hose production process

Raw material selection and proportioning: Select high-quality, fuel corrosion-resistant transparent rubber or plastic raw materials, such as polyurethane (PU), polyvinyl chloride (PVC) or fluoroelastomer, etc., and according to the needs of the product performance of the scientific proportioning.

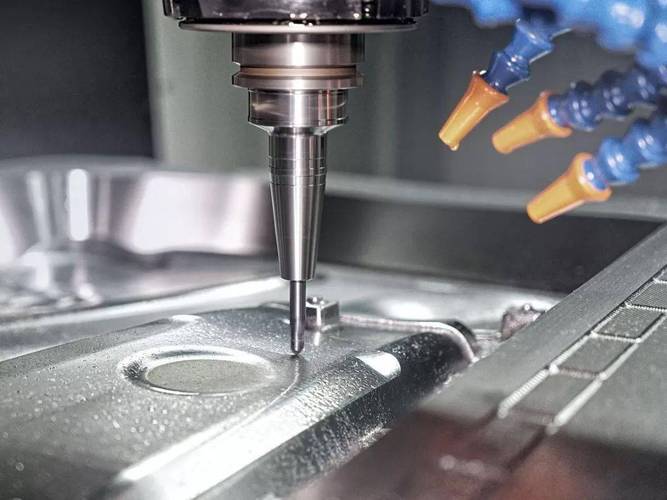

Mixing and Extrusion: The matched raw materials are mixed well in the mixer, and then extruded into tubes through the extruder to form the preliminary form.

Cooling and shaping: The extruded pipe needs to be cooled immediately to fix its shape and size, and at the same time ensure the smoothness and uniformity of the inner and outer walls through the shaping device.

Post-processing: Necessary post-processing operations such as cutting, trimming, punching, etc. are carried out on the tubes to meet the specific requirements of customers in terms of length, interfaces, etc.

Quality Inspection: Strict appearance inspection and performance test (such as fuel corrosion resistance, pressure test, etc.) are carried out on the finished products to ensure that each transparent fuel pipe meets the quality standards.

2.Transparent fuel pipe customization

Size customization: According to customer requirements, we provide customized transparent fuel hose with different diameters, wall thicknesses and lengths to ensure a perfect match with the fuel system.

Color and Transparency Customization: Although transparent fuel hose is mainly transparent, we can also provide specific color or transparency customization service according to customers’ requirements to meet individual needs.

Interface customization: We provide customized services of various interface forms (such as quick couplings, threaded couplings, etc.) to ensure the reliable connection between the fuel hose and other components.

Performance customization: According to the fuel type, working environment and other factors, adjust the fuel corrosion resistance, high pressure resistance, low temperature resistance and other properties of transparent fuel hose to meet the needs of specific application scenarios.

3. Transparent fuel hose material introduction

Material: polyurethane (PU), polyvinyl chloride (PVC), fluoroelastomer and so on.

Characteristics:

High transparency: easy to observe the fuel flow status and detect potential problems in time.

Fuel corrosion resistance: can withstand gasoline, diesel fuel and other fuel corrosion for a long time, to maintain the structural integrity of the pipeline.

Good flexibility: easy to bend and install, adapt to a variety of complex fuel system layout.

High pressure resistance: can withstand a certain pressure to ensure the normal operation of the fuel system.

4. Transparent fuel pipe characteristics of different materials

4.1 Polyurethane (PU) transparent fuel line:

Fuel corrosion resistance: excellent, can be used in gasoline and diesel fuel system for a long time.

Flexibility: good, easy to bend and install.

High pressure resistance: generally up to 1.6MPa or more.

Operating temperature range: -40℃ to +80℃.

4.2 Polyvinyl chloride (PVC) transparent fuel hose:

Fuel corrosion resistance: good, suitable for most fuel systems.

Flexibility: moderate, suitable for general fuel system layout.

High pressure resistance: generally up to 1.0MPa or more.

Operating temperature range: -10℃ to +60℃.

4.3 Viton transparent fuel hose:

Fuel corrosion resistance: excellent, suitable for highly corrosive fuel systems.

Flexibility: good, can maintain stable performance in extreme environments.

High pressure resistance: generally up to 2.5MPa or more.

Operating temperature range: -20℃ to +150℃.

Customized Transparent Fuel Hose Service FAQ

Q1: What sizes can be customized for transparent fuel hose?

A1: We can provide customized transparent fuel hose with different diameters, wall thicknesses and lengths according to customers’ needs to ensure a perfect match with your fuel system.

Q2: What materials are available for clear fuel lines?

A2: We offer a wide range of materials such as polyurethane (PU), polyvinyl chloride (PVC), Viton and other materials for customers to choose from to meet the needs of different application scenarios.

Q3: What is the fuel corrosion resistance of transparent fuel hose?

A3: The fuel corrosion resistance of transparent fuel hose varies depending on the material, but our products are rigorously tested to ensure that they can withstand the corrosion of gasoline, diesel and other fuels for a long time.

Q4:How long is the customization period of transparent fuel hose?

A4: The customization cycle varies depending on the order quantity and production arrangement, generally we will arrange the production as soon as possible after receiving the order and deliver the products within the agreed time. If there is any urgent demand, please communicate with us in advance so that we can try our best to meet it.

Through the above introduction, I believe you have a better understanding of customized clear fuel hose. If you have any questions or needs, please feel free to contact us.