Author: LI

15+ years experience in custom transparent plastic manufacturing | Updated: January 27, 2026

Why Custom Transparent Plastic Parts?

Bro, let me tell you – transparent plastics are absolute game-changers in the manufacturing world! These crystal-clear components offer the perfect blend of optical clarity, strength, and design flexibility that traditional materials like glass just can’t match.

First off, they’re incredibly lightweight – like, half the weight of glass! Imagine the possibilities for products where weight matters – from medical devices to automotive components. And don’t even get me started on the impact resistance – some of these plastics are virtually unbreakable compared to fragile glass.

The design freedom? Unreal. You can mold transparent plastics into complex shapes that would be impossible or prohibitively expensive with glass. Plus, they’re much easier to fabricate, machine, and assemble.

And let’s talk about cost – transparent plastics are often 50-70% cheaper than glass for comparable applications, especially when you factor in manufacturing and shipping savings.

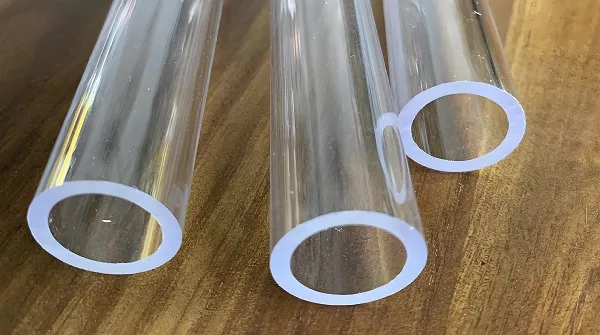

High-clarity transparent plastic component – notice the exceptional light transmission quality

Key Advantages at a Glance:

Transparent Plastic Materials: Choose Your Weapon!

Alright, let’s talk materials – because not all transparent plastics are created equal, my friend. Each has its own superpowers and weaknesses. Let me break down the main players:

PMMA (Acrylic/Plexiglass)

The clarity king – this stuff has 92% light transmission, that’s better than glass! It’s the go-to when optical clarity is non-negotiable.

Light Transmission: 92% (ASTM D1003)

Haze: ≤1% (ISO 14782)

Impact Strength: 2-3 kJ/m²

Temp Range: -40°C to 80°C

Best for: Lenses, displays, signage, lighting covers

Warning: Brittle compared to PC – can crack under heavy impact!

PC (Polycarbonate)

The impact monster – this is the plastic they use for bulletproof glass! Virtually unbreakable while still maintaining great clarity.

Light Transmission: 89-90% (ASTM D1003)

Haze: ≤2% (ISO 14782)

Impact Strength: 60-70 kJ/m²

Temp Range: -40°C to 135°C

Best for: Safety shields, automotive components, medical devices

Pro Tip: Prone to scratching – consider hard coating for exposed applications!

PET/PETG

The workhorse – balanced properties at a great price point. Excellent chemical resistance and recyclable too!

Light Transmission: 88-90% (ASTM D1003)

Haze: ≤1.5% (ISO 14782)

Impact Strength: 15-20 kJ/m²

Temp Range: -40°C to 70°C

Best for: Packaging, medical devices, consumer goods

Eco Bonus: Fully recyclable and often made from recycled materials!

Material Showdown: Which One Wins?

| Property | PMMA (Acrylic) | PC (Polycarbonate) | PETG |

|---|---|---|---|

| Light Transmission | 92% (Best) | 90% (Excellent) | 89% (Very Good) |

| Impact Resistance | Poor (2-3 kJ/m²) | Excellent (60-70 kJ/m²) | Good (15-20 kJ/m²) |

| Scratch Resistance | Good | Poor | Very Good |

| Chemical Resistance | Poor | Good | Excellent |

| Cost (per kg) | $2.5-3.5 | $3.5-5.0 | $2.0-3.0 |

Manufacturing Processes: How We Make These Clear Wonders

Making transparent plastic parts is part art, part science. Let me walk you through the main processes we use. Each has its pros and cons, and we choose based on what the project needs.

1. Injection Molding

This is the big dog for high-volume production. We melt plastic pellets and inject them into precision molds under high pressure. The results? Complex parts with tight tolerances (±0.05mm) and consistent optical quality.

Perfect for when you need 10,000+ parts – the mold costs get spread out, making it super cost-effective. The surface finish is usually excellent right out of the mold, minimal post-processing needed.

Best for: High-volume production, complex geometries, consistent quality

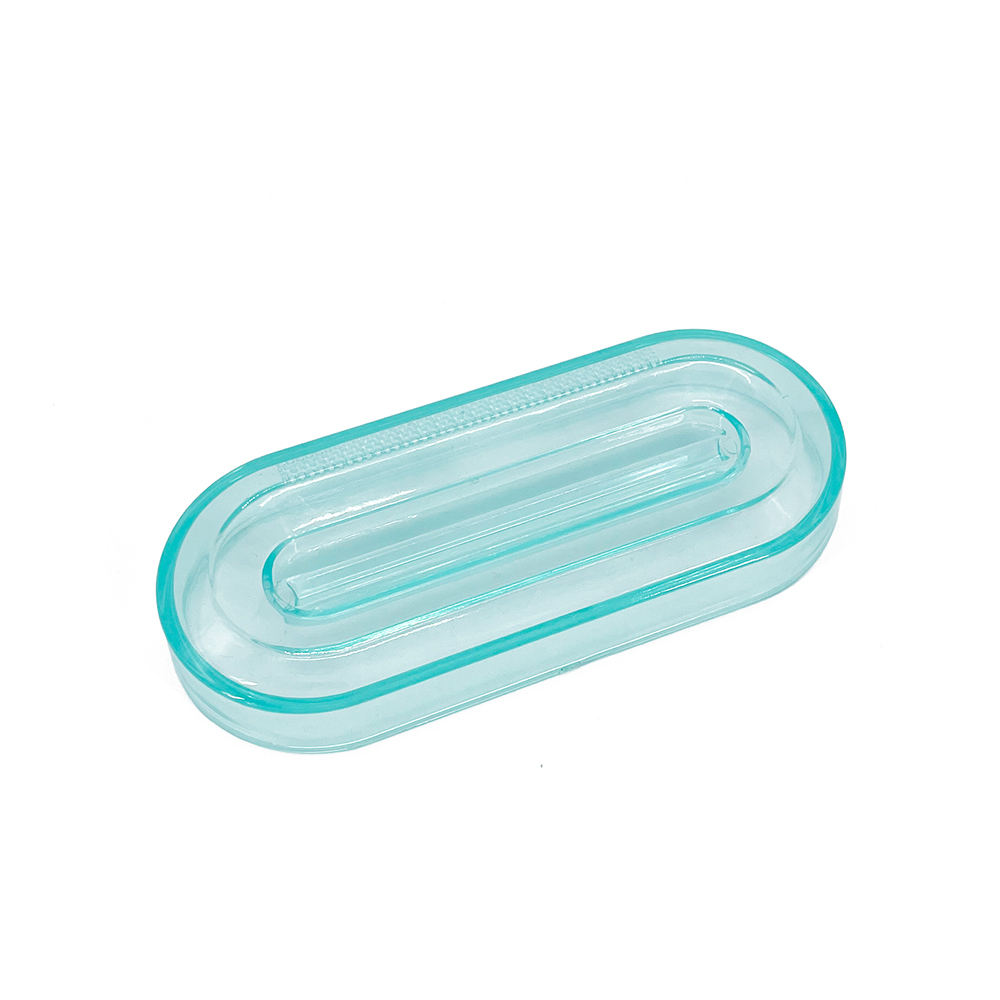

Precision injection molded transparent plastic components – notice the intricate details

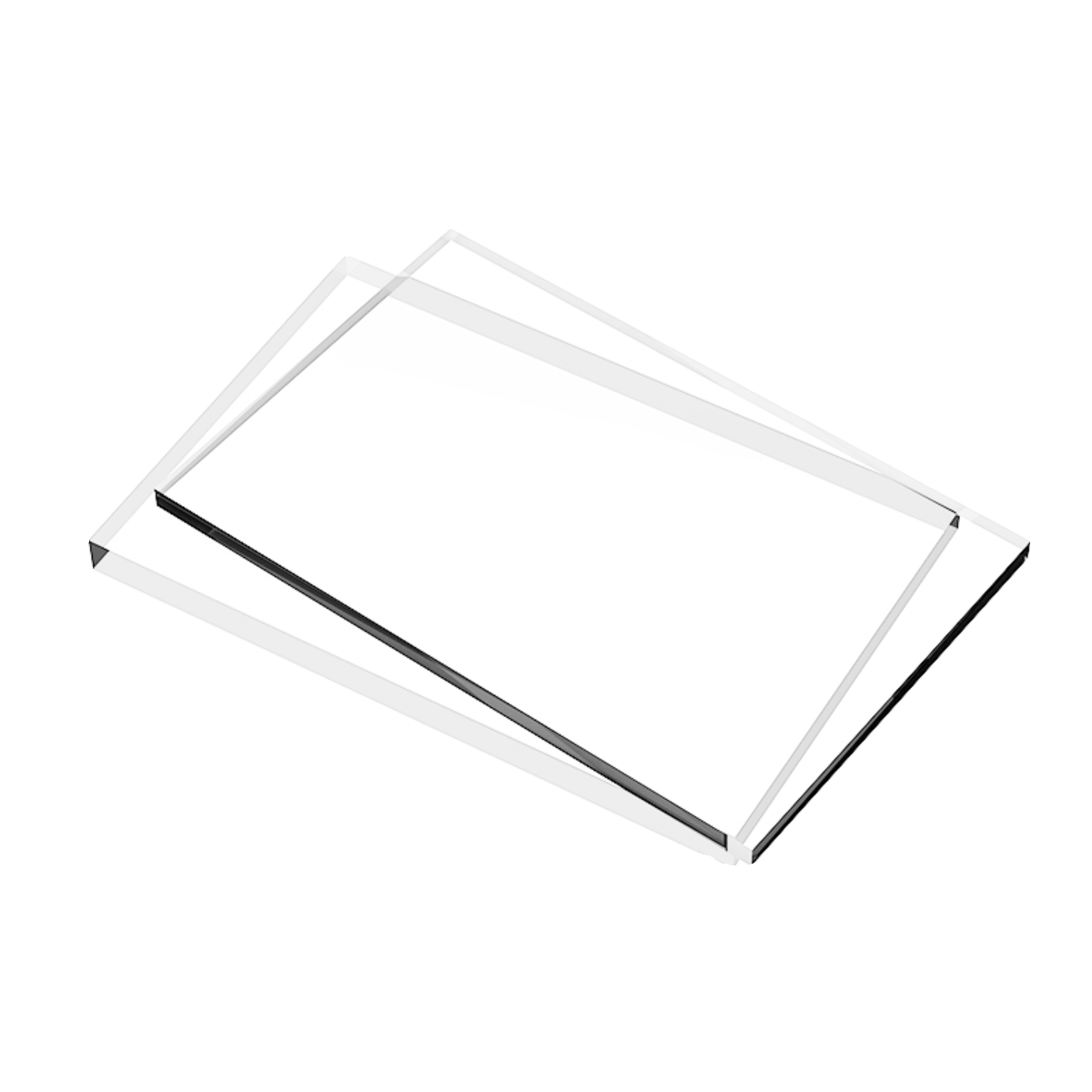

Clear acrylic sheets ready for CNC machining – optical grade quality

2. CNC Machining

For low-volume or prototype work, CNC machining is where it’s at. We cut parts from solid plastic blocks using computer-controlled tools. The precision? ±0.02mm – that’s like splitting a human hair!

The best part? Quick modifications. If you need to tweak a design, we can adjust the CNC program and have a new part in hours, not days. Perfect for testing different designs or when you only need 1-100 pieces.

Best for: Prototypes, low-volume production, quick design changes

3. Thermoforming

This is great for large, shallow parts. We heat a plastic sheet until it’s pliable, then use vacuum pressure to form it over a mold. Perfect for things like display cases, machine guards, and skylights.

The tooling costs are much lower than injection molding, making it ideal for medium-volume production of large parts. The optical quality is excellent, and you can get some really cool shapes.

Best for: Large parts, shallow geometries, medium volume

Thermoformed transparent plastic panel with precision cutouts

Process Comparison: Which One’s Right For You?

| Process | Tolerance | Volume | Lead Time | Cost |

|---|---|---|---|---|

| Injection Molding | ±0.05mm | High (10k+) | 2-4 weeks | Low per unit |

| CNC Machining | ±0.02mm | Low (1-100) | 1-3 days | High per unit |

| Thermoforming | ±0.1mm | Medium (100-10k) | 1-2 weeks | Medium per unit |

Testing & Standards: We Don’t Guess, We Test!

Look, anyone can make a transparent part – but making a quality transparent part that actually performs? That requires some serious testing. We put our transparent plastics through the wringer to make sure they can handle whatever your application throws at them.

Optical Testing

This is where transparent plastics live or die! We test every batch for optical performance:

- Light Transmission: Up to 92% (ASTM D1003)

- Haze Measurement: ≤1% (ISO 14782)

- Clarity: Visual inspection and quantitative analysis

- Color: CIE Lab color space measurements

Test data shown is for reference only – actual results may vary based on material grade and thickness

Mechanical Testing

Transparent parts need to be strong too! We test the mechanical properties rigorously:

- Impact Strength: 2-70 kJ/m² (Charpy, Izod)

- Tensile Strength: 50-70 MPa (ASTM D638)

- Flexural Modulus: 2-3 GPa (ASTM D790)

- Hardness: 70-100 Shore D

Real World Test: Our PC parts survived 2m drop tests onto concrete without cracking!

Environmental Testing

Parts don’t live in perfect conditions, so we test them in real-world environments:

- Temperature Range: -40°C to 135°C

- UV Resistance: 500+ hours QUV exposure

- Chemical Resistance: Oils, solvents, cleaning agents

- Humidity: 95% RH for 1000 hours

Critical: PMMA can yellow in UV exposure – use UV-stabilized grades outdoors!

Industry Standards We Meet

Applications: Where These Clear Parts Shine

Transparent plastics are like the Swiss Army knives of the manufacturing world – they’re everywhere! Let me show you some of the cool places we’ve seen them in action:

Medical & Healthcare

Bro, these are perfect for medical applications! They’re clear, sterilizable, and meet strict FDA standards (21 CFR 177.1520).

- Face shields and protective barriers

- Medical device housings and windows

- IV fluid containers and lab equipment

- Surgical instrument components

Success Story: We supplied 50,000 PC face shields during the pandemic – they withstood repeated sterilization and maintained clarity!

Automotive & Transportation

Cars are all about safety and weight reduction – transparent plastics deliver both in spades!

- Headlight and taillight lenses

- Instrument cluster covers and displays

- Sunroofs and window components

- Interior lighting and trim parts

Fun Fact: Using PC headlight lenses reduces weight by 60% compared to glass and won’t shatter in accidents!

Lighting & Optics

When light transmission matters most, these plastics are unbeatable. They’re used in everything from LED bulbs to high-end optics.

- LED light covers and diffusers

- Lenses for projectors and cameras

- Light guides and optical components

- Solar panel covers and light pipes

Pro Application: Our PMMA light guides for LED lighting achieve 95% light transmission efficiency!

Cool Niche Applications You Might Not Expect!

Surface Treatments: Taking Parts to the Next Level

Okay, so basic transparent parts are great – but what if you need even more performance? We’ve got you covered with these awesome surface treatments:

Hard Coating

This is like giving your parts a suit of armor! We apply a thin, tough coating that dramatically improves scratch resistance:

- Scratch Resistance: +400% improvement (up to 3H pencil hardness)

- UV Protection: Prevents yellowing and degradation

- Chemical Resistance: Better protection against solvents

- Durability: Lasts the lifetime of the part

Test Result: Hard-coated PC survived 1000 cycles of steel wool rubbing without visible scratches!

Anti-Reflective (AR) Coating

For applications where glare is a problem, AR coatings are a game-changer. They reduce reflections and improve visibility:

- Reflection Reduction: From 8% to <1% per surface

- Light Transmission: Increases by 3-5%

- Visibility: Dramatically improved in bright conditions

- Aesthetics: Cleaner, more professional appearance

Perfect for: Displays, lenses, windows, optical components

Anti-Fog Coating

For parts that encounter temperature changes or humidity, anti-fog coatings prevent condensation buildup:

- Fog Prevention: Works in high humidity environments

- Durability: Resists washing and cleaning

- Clarity: Maintains optical performance

- Application: One-time treatment, lasts for years

Medical Use: Critical for face shields, goggles, and surgical equipment!

Anti-Static Coating

For electronics and cleanroom applications, anti-static coatings prevent static buildup and dust attraction:

- Static Dissipation: Surface resistance 10⁹-10¹¹ ohms

- Dust Resistance: Reduces particle attraction

- Protection: Safeguards sensitive electronics

- Cleanroom: Meets ISO 14644-1 standards

Essential for: Electronics manufacturing, medical devices, optics

Frequently Asked Questions (Straight Talk!)

Q: How do I choose between PMMA, PC, and PETG?

A: Great question! Let me break it down for you in plain English:

- PMMA (Acrylic): Best clarity (92% light transmission) but brittle. Use when optical quality is #1 priority.

- PC (Polycarbonate): Super tough (unbreakable!) but scratches easily. Use when impact resistance matters most.

- PETG: Balanced properties at a great price. Good chemical resistance too. Great all-around choice.

Pro Tip: If you need both clarity and toughness, go with PC + hard coating!

Q: Can transparent plastics be used outdoors?

A: Absolutely, but you need to choose the right materials and treatments:

- UV Stabilization: Must-have for outdoor use – prevents yellowing and degradation

- Material Choice: PC is better than PMMA for outdoor applications

- Hard Coating: Adds scratch resistance and extra UV protection

- Lifespan: With proper treatment, expect 5-10 years outdoors

Real Example: Our UV-stabilized PC skylights have been in service for 8 years with no yellowing!

Q: What’s the minimum order quantity for custom parts?

A: This is one of my favorite things – we’re flexible! Here’s the real deal:

- CNC Machining: 1 piece minimum (great for prototypes)

- Injection Molding: Typically 1,000+ pieces, but we can do smaller runs with aluminum molds

- Thermoforming: 100+ pieces depending on size

- Pricing: The more you order, the lower the per-unit cost (duh!)

Q: How do I ensure my design is manufacturable?

A: Glad you asked! Design for manufacturability (DFM) is crucial. Here’s what we look for:

Design Guidelines:

- Wall thickness: 1.5-4mm (uniform is best)

- Draft angles: 1-2° per side

- Radius corners: No sharp internal corners

- Tolerances: ±0.05mm for critical features

Material Considerations:

- Shrinkage: Account for 0.5-0.8% shrinkage

- Gate location: Avoid visible gates on cosmetic surfaces

- Weld lines: Design to minimize or hide them

- Surface finish: Mold texture vs. post-processing

Free DFM Analysis: We’ll review your design for free and suggest improvements!

Q: What’s the typical lead time for custom parts?

A: Lead times depend on the process and complexity, but here’s a realistic timeline:

- Prototypes (CNC): 3-5 days

- Small Production (100-1000): 1-2 weeks

- Large Production (10k+): 3-4 weeks (includes mold making)

- Rush Service: We can do prototypes in 24-48 hours for emergency cases

Pro Tip: Plan ahead! Rushing always costs more and can compromise quality.

Ready to Create Your Custom Transparent Parts?

Whether you need precision medical components, durable automotive parts, or crystal-clear optical elements, we have the expertise and capabilities to deliver exactly what you need.

Our team of engineers will work with you to select the perfect material, optimize your design for manufacturability, and ensure your parts meet the highest quality standards.