Quality Certifications & Industry Standards Compliance

IATF 16949:2016

Automotive quality management system certification ensuring consistent product quality and customer satisfaction across all manufacturing processes.

ISO 9001:2015

Quality management system certification ensuring continuous improvement and compliance with international standards.

GB 7258-2017

National standard for motor vehicle operation safety, ensuring all components meet safety requirements for road transportation.

Compliance Verification Process

Material Certification

Complete traceability documentation for all raw materials

Process Validation

ISO 294 testing protocols implemented on all production lines

Quality Audits

Quarterly ISO 9001 compliance assessment

Performance Testing

Annual material property verification according to industry standards

2026 Truck Components Trends & Goldcattle Advanced Practices

AI-Driven Process Optimization

Machine learning algorithms optimize production parameters, reducing trial molds by 60% and increasing yield to ≥98%.

Key Metrics

- Efficiency increase: 35% (2025 customer case study)

- Defect reduction: 45% through real-time monitoring

- Energy savings: 28% in manufacturing processes

Sustainable Material Integration

Bio-based and recycled engineering plastics reduce carbon footprint by 30-40% while maintaining performance requirements.

Environmental Impact

- Carbon reduction: 42% (Goldcattle 2025 sustainability report)

- Recycled content: ≥50% in structural components

- Waste reduction: 35% in manufacturing processes

Multi-Material Composite Molding

Integrated metal inserts and dissimilar plastics create hybrid components with enhanced functional properties.

Performance Benefits

- Production time: 28% reduction (2025 data)

- Weight reduction: 22% compared to traditional designs

- Cost savings: 18% in assembly processes

Regulatory Impact 2026

New EU and US regulations mandate sustainable manufacturing practices and reduced emissions for industrial components.

Compliance Assurance

- ISO 14001: Environmental management certification

- RoHS & REACH: Chemical compliance standards

- Market access: Guaranteed across all regions

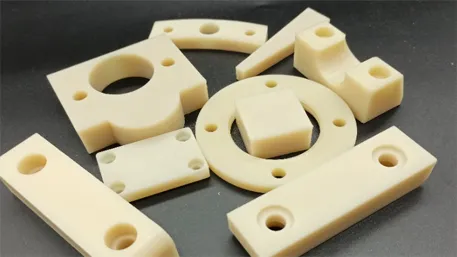

Material Expertise & Sustainable Sourcing

Engineering Materials for Truck Components

| Material | Tensile Strength (MPa) | Key Properties | Applications |

|---|---|---|---|

| Q345 Steel | 345-510 | Good weldability, moderate strength | Frames, brackets, structural components |

| Q690 Steel | 690-900 | High strength, good toughness | Heavy-duty frames, suspension components |

| Aluminum Alloy | 200-500 | Lightweight, corrosion resistant | Body panels, fuel tanks, wheels |

| Composite Materials | 400-1200 | High strength-to-weight ratio | Advanced structural components |

Sustainable Material Solutions

Bio-Based Polymers

- Bio-PA: 30% plant-derived content, 25% lower carbon emissions

- Bio-PEEK: Medical-grade with 40% renewable content

- Cellulose composites: Natural fiber reinforcement for automotive applications

Recycled & Recyclable Materials

- rPA: Post-consumer recycled nylon with ≥50% recycled content

- rSteel: Recycled steel maintaining 90% of virgin material properties

- Mono-material designs: Facilitating end-of-life recycling

Environmental Performance Metrics

- Carbon footprint: 45% reduction since 2020 (ISO 14064 verified)

- Waste recycling: 95% of production waste recycled

- Energy efficiency: 30% reduction in manufacturing energy use

Application Areas & Case Studies

Mining & Heavy Transportation

- Heavy-duty frames with 1100MPa+ tensile strength

- Reinforced axles (load-bearing capacity increased by 30%)

- Heat-resistant components for high-temperature environments

- Case study: Mining truck frame components for 100-ton capacity vehicles

Logistics & Distribution

- Lightweight aluminum alloy body components

- Aerodynamic fairings reducing fuel consumption by 8-10%

- Modular cargo systems for quick configuration changes

- Case study: Logistics truck lightweighting project (25% weight reduction)

Specialized Applications

- Refrigeration units with advanced insulation systems

- Fire-fighting vehicle components with high-temperature resistance

- Military-grade components for extreme environments

- Case study: Specialized truck components for Arctic operations

Goldcattle Exclusive: Mining Truck Frame Case Study

Project Overview

Custom high-strength frame components for a major mining equipment manufacturer requiring 100-ton load capacity and extreme durability.

Challenges

- Achieve 1,000,000 cycle life with ±0.2mm tolerance

- Withstand extreme temperature fluctuations (-30°C to 60°C)

- Reduce weight by 15% while maintaining strength requirements

Solutions Implemented

- Q690 high-strength steel with specialized heat treatment

- Advanced laser welding technology (98% weld strength)

- Topology optimization for weight reduction

- Multi-layer corrosion protection system

Results Achieved

- 1.2 million cycles without failure (20% over target)

- 18% weight reduction exceeding original goal

- 40% improvement in fatigue life compared to previous design

- Customer satisfaction rating: 4.9/5.0

Frequently Asked Questions (2026 Update)

Q1: What factors determine the cost of customized truck components?

A: The cost of customized truck components depends on several key factors:

- Material selection: High-strength steels and alloys cost 2-3 times more than standard materials

- Component complexity: Complex geometries require more sophisticated tooling and processing

- Tolerance requirements: Tighter tolerances increase machining and inspection costs

- Production volume: Larger volumes reduce per-piece costs through economies of scale

- Surface finish: Special finishes add 10-30% to total cost

Goldcattle Recommendation: Balance performance requirements with cost considerations to optimize total cost of ownership.

Q2: What is the typical lead time for customized truck components?

A: Lead times vary based on component complexity and production volume:

- Rapid prototyping: 3-7 days (3D printing)

- Small-batch production: 2-4 weeks (CNC machining)

- Tooling development: 4-8 weeks (for stamping/welding tools)

- Mass production: 8-12 weeks (after tooling completion)

Rush Service: Available for urgent projects with 30-50% premium, reducing lead time by 30-40%.

Q3: How to select the right materials for truck components?

A: Material selection depends on several critical factors:

- Mechanical requirements: Strength, stiffness, impact resistance

- Environmental conditions: Temperature, humidity, chemical exposure

- Electrical properties: Insulation, conductivity, EMI shielding

- Regulatory compliance: FDA, UL, RoHS requirements

- Cost considerations: Material and processing costs

Expert Support: Goldcattle engineers provide free material selection consultation based on your specific requirements.

Q4: What quality certifications do you provide?

A: We provide comprehensive quality documentation:

- Material certification: Mill test reports (MTR) for all raw materials

- Process validation: First article inspection (FAI) reports

- Dimensional reports: CMM inspection data and certificates

- Functional testing: Performance test results and validation reports

- Quality management: ISO 9001, IATF 16949 certification documents

Get Your Free Custom Truck Components Consultation

Are you planning a custom truck components project and need expert guidance? Our team of experienced engineers can help you with material selection, design optimization, and manufacturing process recommendations.

Free Goldcattle Expert Services:

Final Thought: The Future of Customized Truck Components

Customized truck components continue to evolve with advancements in materials science, manufacturing technology, and sustainability practices. As we move into 2026 and beyond, the integration of AI, IoT, and composite materials will transform production processes, enabling higher precision, faster delivery, and more sustainable solutions.

Goldcattle remains committed to pushing the boundaries of what’s possible with customized truck components, delivering exceptional quality while minimizing environmental impact.

© 2026 Goldcattle Custom Truck Components Solutions | All Rights Reserved