A Simple Introduction to Modern Dental Manufacturing Technology

1. What is Dental Injection Molding?

It’s as simple as making ice cubes:

- Pour melted material into a mold

- Wait for the material to cool and harden

- Remove the perfectly shaped dental product

This technology is mainly used to make dentures, dental crowns, bridges, and other dental restorations.

2. Basic Working Principle

The injection molding process is straightforward:

Step 1: Heat the Material

- Heat special plastic or resin material to a molten state

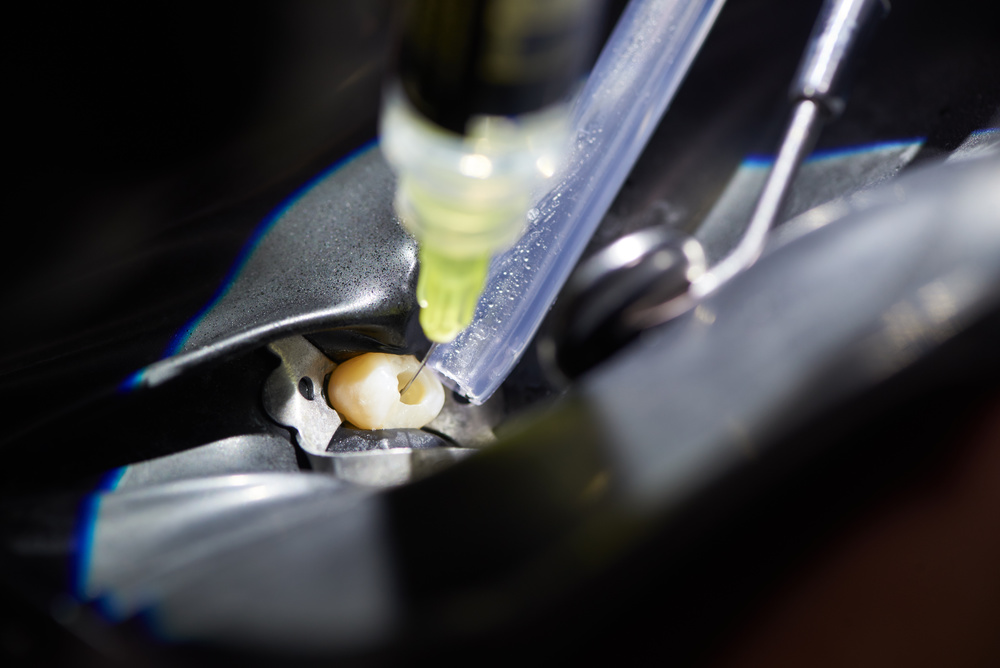

Step 2: Inject into Mold

- Use pressure to inject the melted material into a precise mold

Step 3: Cool and Solidify

- Wait for the material to cool and harden inside the mold

Step 4: Remove the Finished Product

- Open the mold and take out the perfectly formed dental product

3. Main Material Types

Dental injection molding uses several special materials:

Nylon Materials

- Plastic-like but softer and more flexible

- Suitable for making removable dentures

- Oral-friendly and non-allergenic

Resin Materials

- Available in different colors to match natural teeth

- Transparent or translucent

Composite Materials

- Combine the advantages of multiple materials

- High strength and durability

- Natural and aesthetic appearance

4. Common Equipment

Making dental products requires some special machines:

Injection Molding Machine

- Responsible for heating and injecting materials

- Available in different sizes and models

Molds

- Precisely made metal or silicone molds

- Determines the final shape of the product

Heating Furnace

- Used to heat materials to the correct temperature

- Precise temperature control

Cooling System

- Helps materials cool and solidify quickly

5. Manufacturing Process

Making a dental product usually involves these steps:

Step 1: Design the Mold

- Create a precise mold based on the patient’s dental condition

- Ensure perfect dimension matching

Step 2: Prepare Materials

- Select the appropriate material color and type

- Prepare the required amount of material

Step 3: Heat the Material

- Place the material in the heating furnace

- Wait for the material to completely melt

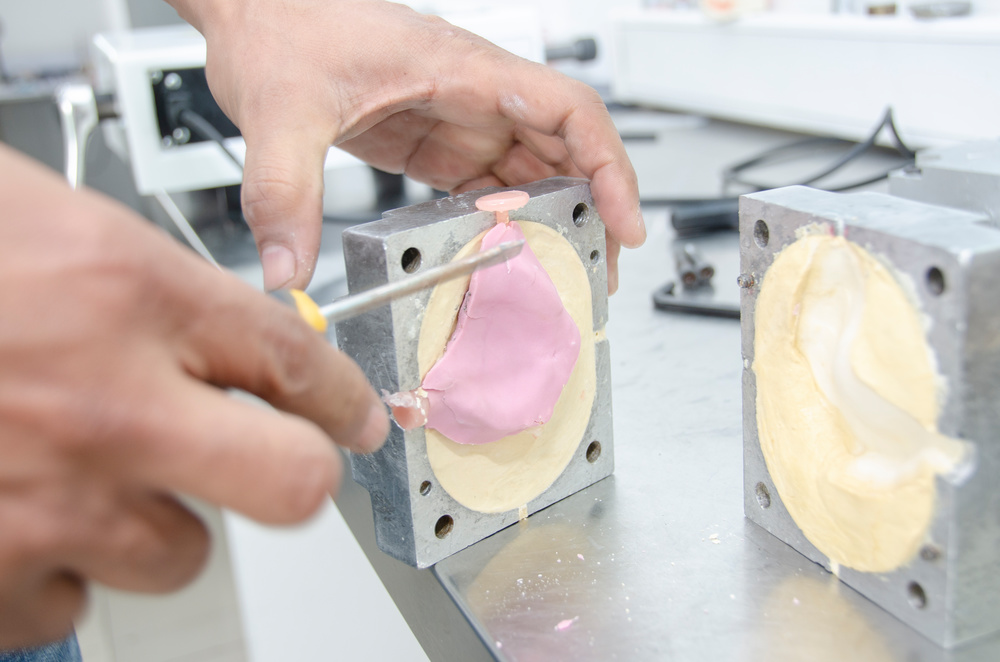

Step 4: Injection Molding

- Inject the melted material into the mold

- Maintain proper pressure and time

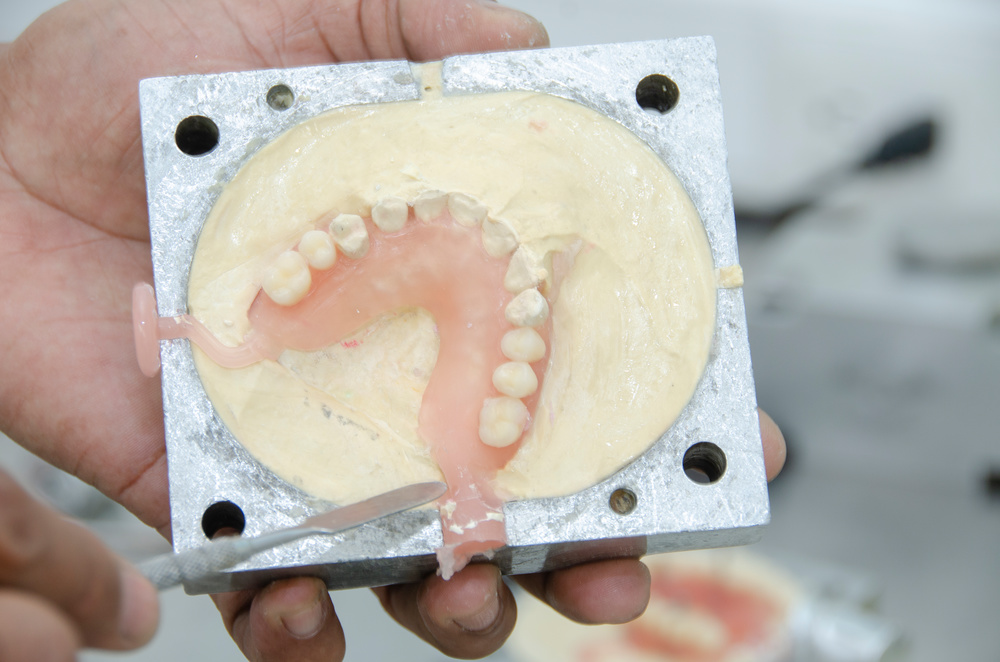

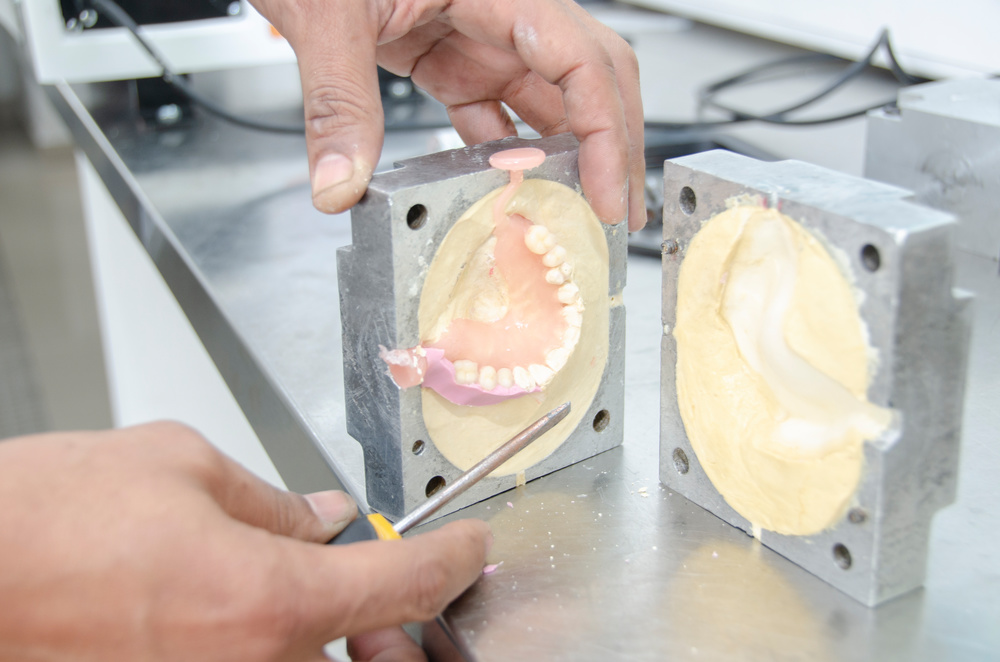

Step 5: Cooling and Demolding

- Wait for the product to cool and harden

- Carefully remove the finished product

Step 6: Finishing and Polishing

- Perform necessary finishing and polishing

6. Main Advantages

Dental injection molding offers many benefits:

More Precise

- Products have very accurate dimensions

- Perfectly match natural teeth

Faster Production

- Less waiting time for patients

More Aesthetic

- Colors can be precisely matched

- Smooth and natural surface

More Comfortable

- Materials are soft and flexible

More Economical

- Relatively low manufacturing cost

7. Application Scenarios

This technology can make many dental products:

Removable Dentures

- Dentures that can be taken out

- Suitable for patients missing multiple teeth

Dental Crowns

- Protective covers for damaged teeth

- Restore tooth shape and function

Dental Bridges

- Restorations that connect missing teeth

Mouthguards

- Commonly used for sports protection

Temporary Restorations

- Temporary dental products

- Used while permanent products are being made

8. Material Requirements

Dental materials must meet strict requirements:

Biocompatibility

- Harmless to the human body

Strength Requirements

- Sufficiently strong and durable

- Can withstand chewing pressure

Aesthetic Requirements

Safety Requirements

Processing Performance

- Maintain shape stability after cooling

9. Quality Control

Ensuring product quality is important:

Material Inspection

- Check if materials meet standards

- Test material performance

Dimension Check

- Measure precise dimensions of products

- Ensure consistency with molds

Appearance Inspection

- Check if surfaces are smooth

Function Testing

- Ensure it meets usage requirements

Safety Testing

- Ensure it’s harmless to patients

10. Comparison with Traditional Methods

Injection molding has many advantages over traditional methods:

Traditional Methods

Injection Molding

- Consistent and reliable quality

Key Differences

- Production time: Traditional takes days, injection molding takes hours

- Precision: Injection molding is much more precise

- Cost: Injection molding is more cost-effective

- Quality: Injection molding produces more consistent quality

11. Safety Considerations

Using this technology requires attention to safety:

Material Safety

- Only use certified materials

- Ensure materials are harmless to humans

Equipment Safety

- Operate machines correctly

- Regularly maintain equipment

Operational Safety

- Operators need professional training

- Follow safety operating procedures

Environmental Safety

- Maintain a clean working environment

- Properly dispose of waste materials

Patient Safety

- Disinfect products before use

- Ensure products are suitable for patient use

12. Frequently Asked Questions

Common questions people ask:

Q: Are injection-molded dentures comfortable?

A: Yes, the materials are soft and flexible, making them very comfortable to wear.

Q: Is the production time long?

A: No, it’s usually completed within a few hours.

Q: Is it expensive?

A: No, it’s more economical than traditional methods.

Q: Are the products durable?

A: Yes, the materials are durable and can last for many years.

Q: Can the color match natural teeth?

A: Yes, there are multiple color options available.

Q: Is it harmful to the body?

A: No, the materials undergo strict safety testing.

Summary

Dental injection molding is a modern, efficient, and precise dental technology.

It makes producing dentures, crowns, and other products faster, better, and more affordable.

This technology is changing the dental industry, allowing more people to access high-quality dental services.

Remember:

- Simple and easy-to-understand manufacturing process

- High-quality material selection

- Safe and reliable usage guarantee

This guide was prepared by professional dental technicians and is for informational purposes only. For questions, please consult a professional dentist.