In modern manufacturing, casting processes are one of the core technologies for forming complex metal parts. With the increasing demand for industrial automation and precision machining, choosing the right casting process is crucial for product quality, production cost, and production efficiency. This article will provide a detailed analysis of the technical characteristics, application scenarios, and advantages – disadvantages comparisons of 11 mainstream casting processes, helping manufacturing practitioners make scientific decisions.

I. Overview of Casting Processes

Casting processes involve pouring molten metal into a mold. After cooling and solidifying, a metal part with a specific shape is formed. Its core advantage lies in the ability to form complex structures in one – step, which is suitable for the entire scenario from single – piece trial production to large – scale mass production. According to different mold materials, forming principles, and process parameters, casting processes can be mainly classified into sand casting, die – casting, precision casting, etc., and are widely used in high – end fields such as aerospace, automotive manufacturing, and medical devices.

II. Technical Analysis of Mainstream Casting Processes

1. Sand Casting: The Most Versatile Basic Process

Process Principle: Use silica sand as the main material to prepare the mold. The upper and lower sand boxes are combined to form a cavity. Molten metal is poured into the cavity through the gate, cooled and formed. Finally, break the sand to take out the part and remove the flash.

Typical Applications: Automobile engine blocks, cylinder heads, large – scale mechanical structural parts, etc.

Advantages:

Low mold cost, suitable for small – batch production and medium – to – large – sized parts.

Can cast various metal alloys such as iron, steel, and aluminum.

High process flexibility, supporting complex structure design.

Limitations: Low dimensional accuracy (IT12 – IT16), large surface roughness (Ra12.5 – 50μm), and high subsequent machining requirements.

2. Die – Casting: The First Choice for High – Precision Mass Production

Process Classification:

High – pressure Die – casting: Inject molten metal into a metal mold quickly under a high pressure of 10 – 100MPa, suitable for mass production of precision small parts of non – ferrous alloys such as zinc, aluminum, and magnesium (such as automobile transmission cases).

Low – pressure Die – Casting: Fill the mold under a low pressure of 0.01 – 0.05MPa, suitable for large – sized thin – walled parts (such as automobile wheels).

Technical Advantages:

Dimensional accuracy can reach IT8 – IT10, surface roughness Ra1.6 – 3.2μm.

High production efficiency, with a single – mold cycle time of only a few seconds to tens of seconds.

Can form ultra – thin structures with a wall thickness of 0.5mm.

Disadvantages: High mold cost (ranging from hundreds of thousands to millions), not suitable for high – melting – point metals (such as steel and cast iron).

3. Precision Casting (Investment Casting): Expert in Forming Complex Surfaces

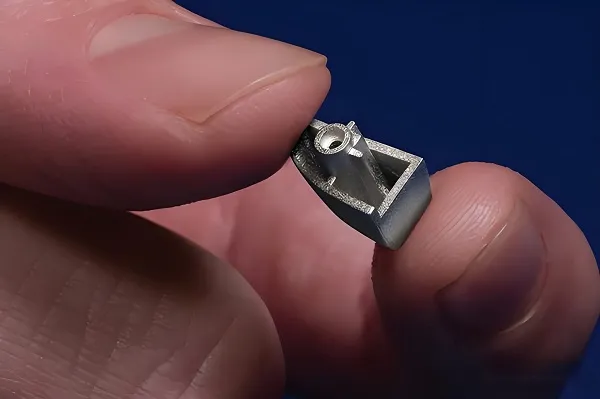

Core Process: Use a wax pattern as a prototype, coat it with refractory materials to make a ceramic shell. After heating to melt and remove the wax pattern, a hollow cavity is formed. Then inject high – temperature alloys (such as stainless steel and titanium alloy) to form the part.

Application Fields: Aero – engine blades, precision parts of medical devices, jewelry, and other parts with complex surfaces.

Unique Advantages:

Can achieve a wall thickness of 0.1mm and an accuracy of 0.05mm.

No draft angle is required, supporting 90° right – angle and deep – cavity structures.

Excellent surface quality, which can be directly polished and chrome – plated.

Challenges: Long process flow (taking 7 – 10 days), material utilization rate of about 60% – 70%, and relatively high cost.

4. Centrifugal Casting: A Powerful Tool for Forming Rotationally Symmetric Parts

Technical Principle: Use centrifugal force (50 – 2000G) to throw molten metal onto the inner wall of a rotating mold, forming high – precision tubular and ring – shaped parts (such as cylinder liners and bearing rings).

Process Advantages:

No shrinkage cavities, pores, and other defects, with a 15% – 20% increase in material density.

No need for gating and riser systems, with a material utilization rate of over 95%.

Surface accuracy can reach IT10 – IT12, and the roundness error is < 0.05mm.

Limitations: Only applicable to rotationally symmetric structures, and large equipment investment (requires a special centrifuge).

5. Lost Foam Casting: A New Green and Environment – friendly Option

Innovation Points: Use a foam plastic pattern instead of the traditional wax pattern. After molding, it is directly buried in a dry sand mold. When the molten metal is poured, the foam pattern vaporizes and disappears, realizing casting without a parting surface.

Typical Products: Automobile body panel molds, pump and valve casings, artistic castings, etc.

Environmental Advantages:

No waste sand discharge, with a sand recovery rate of > 95%.

Eliminates the mold disassembly process, increasing design freedom by 30%.

Suitable for small – batch production of multiple varieties (single – mold cost is 40% lower than the traditional process).

Disadvantages: The foam pattern has low strength, and large parts are prone to deformation. The surface accuracy is slightly lower than that of sand casting.

III. Decision – making Model for Casting Process Selection

1. Structural Complexity

Simple geometric bodies (such as cylinders) → Centrifugal casting / Gravity die – casting

Complex surfaces + Thin walls → Precision casting / Lost foam casting

Extra – large sizes ( > 1m) → Sand casting / Shell molding

2. Production Volume

Single – piece / Small – batch ( < 100 pieces) → 3D – printed casting (combined with 3D – printed wax patterns)

Medium – batch (100 – 5000 pieces) → Lost foam casting / Shell molding

Large – batch ( > 5000 pieces) → High – pressure die – casting / Automated sand casting

3. Material Characteristics

High – melting – point metals (steel, titanium alloy) → Precision casting / Sand casting

Low – melting – point alloys (aluminum, zinc) → Die – casting / Vacuum die – casting

IV. Xiamen Goldcattle Casting Solutions

As an innovator in the field of precision manufacturing, Xiamen Goldcattle, relying on more than 20 years of industry experience, provides a full – process casting process solution:

1. Technical Capability Coverage

Core Processes: Sand casting (accuracy IT12 – IT16), high – pressure die – casting (accuracy IT8 – IT10), investment casting (accuracy IT6 – IT8)

Material Range: Covers more than 50 metal materials including aluminum alloys (ADC12, A356), zinc alloys (ZA27), stainless steels (304, 316), etc.

Production Capacity Configuration: 30 die – casting machines (clamping force 500 – 4000 tons), 10 automated sand – casting production lines, with a monthly production capacity of 5000 tons.

2. Full – process Quality Control

IATF 16949 certification system, with full – process traceability from mold design (UG/NX/CAD) to CMM coordinate measurement (accuracy 0.001mm).

Advanced testing equipment: German Zeiss spectrometer, American GE industrial CT, with a defect detection rate increased to 99.9%.

3. Agile Manufacturing Services

Quick prototyping: 3D – printed wax patterns combined with investment casting, delivering the first piece within 72 hours.

Intelligent quotation: Upload the STL file to the official website and obtain a detailed solution including materials, processes, and costs within 5 minutes.

Global services: Support international trade terms such as DDP/DAP, with overseas warehouses covering major markets in North America and Europe.

V. Conclusion

The choice of casting process is a comprehensive balance of material characteristics, structural design, and production scale. Xiamen Goldcattle is always committed to breaking through process boundaries through technological innovation, providing customers with a one – stop solution from conceptual design to mass production. Contact our engineering team immediately to obtain a customized casting process solution and make precision manufacturing within reach.