Short answer: No, 3D printers can use a wide range of materials beyond plastic, with applications spanning industries from aerospace to healthcare. The choice of material depends on the printing technology, desired properties, and specific use case.

Why plastic is so common in 3D printing?

Plastic remains the most widely used 3D printing material, especially in consumer and entry-level industrial applications, for several practical reasons:

- Cost-effectiveness: Materials like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene) are relatively inexpensive and widely available.

- Ease of use: Thermoplastic filaments work seamlessly with popular FDM (Fused Deposition Modeling) printers, which are affordable and easy to operate.

- Versatility: Plastics offer a good balance of strength, flexibility, and printability for everyday items, prototypes, and decorative objects.

Common plastic materials include:

- PLA: Eco-friendly (made from renewable resources like corn starch), easy to print, and ideal for educational projects or non-functional prototypes.

- ABS: More durable and impact-resistant than PLA, suitable for functional parts like phone cases or mechanical components.

- Nylon: Known for its wear resistance and flexibility, often used in selective laser sintering (SLS) printers for industrial parts.

What other materials can 3D printers use?

3D printing technology has evolved far beyond plastics. Here are key material categories and their applications:

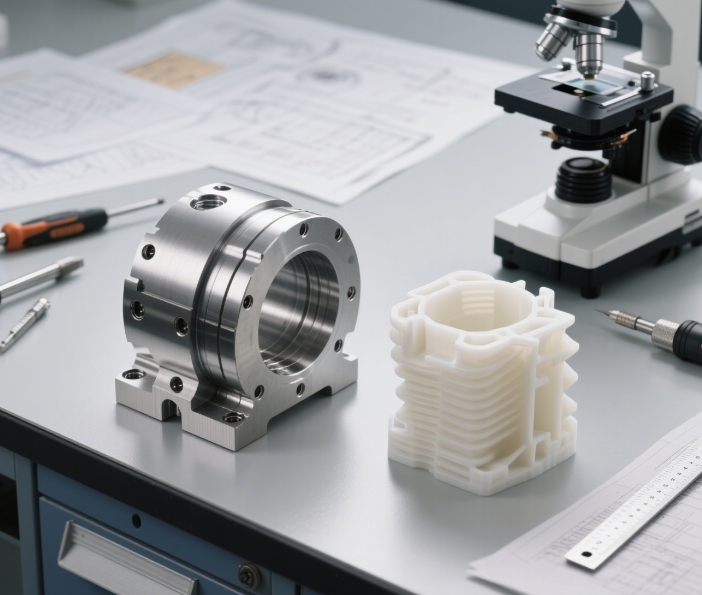

1. Metals

Metal 3D printing is a game-changer in high-performance industries. Common metals include titanium alloys, stainless steel, aluminum, and even precious metals like gold and silver.

- Technology: Processes like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) melt metal powders layer by layer to create strong, precise parts.

-

- Aerospace: Lightweight titanium components for aircraft engines and frames.

-

- Medical: Custom orthopedic implants (e.g., hip replacements) tailored to a patient’s anatomy.

-

- Automotive: High-strength gears and engine parts optimized for performance.

2. Ceramics

Ceramic materials offer high heat resistance, biocompatibility, and electrical insulation, making them valuable in specialized fields:

- Materials: Alumina, zirconia, and silicon carbide.

-

- High-temperature components like turbine blades and furnace parts.

-

- Biomedical implants (e.g., dental crowns) due to their biocompatibility and natural look.

-

- Electronic insulators and advanced sensors.

3. Composites

Composite materials combine polymers with reinforcing fibers to enhance strength, stiffness, or lightweight properties:

- Examples: Carbon fiber-reinforced PLA, glass fiber-reinforced nylon.

-

- Aerospace and automotive: Lightweight structural parts that reduce fuel consumption.

-

- Sports equipment: Custom bike frames, golf club heads, and protective gear.

4. Biomaterials

In bioprinting, living cells and biocompatible gels (called bioinks) are used to create tissues and organ models:

-

- Drug testing: 3D-printed liver or kidney models to study how drugs interact with human tissue.

-

- Regenerative medicine: Skin grafts for burn victims and cartilage implants for joint repair.

-

- Future potential: Lab-grown organs for transplantation (still in experimental stages).

5. Other innovative materials

- Glass: Used in high-precision optics, art installations, and complex lab equipment.

- Concrete: Large-scale 3D printers build houses and bridges with sustainable, low-waste construction.

- Food materials: Chocolate, dough, and pureed foods are 3D-printed for custom shapes in restaurants and food tech.

How do printing technologies affect material choices?

Different 3D printing technologies are designed for specific materials:

- FDM/FFF: Works with thermoplastic filaments (PLA, ABS).

- SLA/DLP: Uses photopolymer resins cured by light, producing high-detail models.

- SLS/SLM: Sinter or melt powders (nylon for SLS, metals for SLM).

- Binder Jetting: Binds metal, ceramic, or sand powders with a liquid binder, often used for molds or large structures.

Common Questions About 3D Printing Materials

1. Are non-plastic 3D printing materials more expensive than plastic?

Yes, in most cases. Metals, advanced composites, and biomaterials typically cost more due to raw material costs, specialized processing, and higher printer requirements. For example, metal 3D printing powders can be 10–50 times pricier than PLA filament, but their performance benefits justify the cost in high-value applications like aerospace or medical.

2. Can home 3D printers use materials other than plastic?

Most consumer-grade printers (like FDM models) are limited to plastics, but some modified home setups can handle basic composites (e.g., wood-filled PLA). Metals, ceramics, or biomaterials require industrial-grade printers with high-temperature chambers, laser systems, or sterile environments, which are not feasible for home use.

3. How do I choose the right 3D printing material for my project?

Start by defining your needs:

- Function: Does the part need strength, flexibility, or heat resistance?

- Budget: Plastic is best for low-cost projects; metals/composites for high-performance needs.

- Printer type: Check if your printer supports the material (e.g., FDM can’t print metal).

- Post-processing: Some materials (like ceramics) require firing after printing, adding steps to the workflow.

4. Are 3D printing materials recyclable?

Many plastic filaments (PLA, ABS) are recyclable, and some companies offer recycling programs for used prints. However, composite or metal materials are harder to recycle due to mixed components. Biodegradable options like PLA break down in industrial composting facilities, making them eco-friendlier for single-use items.