Introduction: Unlocking Core Technology for Unconventional Part Manufacturing

Chapter 1: Basic Understanding – What is Eccentric Turning?

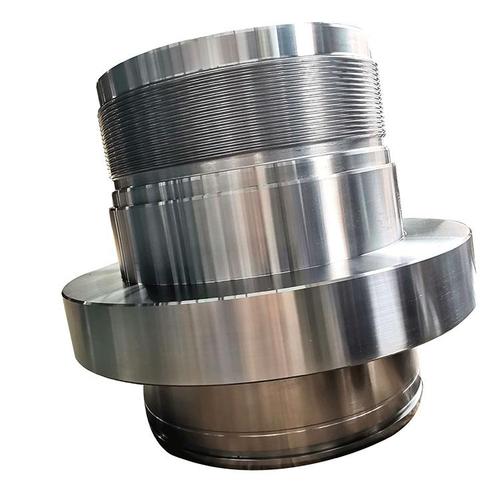

1.1 Core Definition

1.2 Vivid Analogy

1.3 Key Terminology Explanation

Chapter 2: Value and Applications – Why Do We Need Eccentric Turning?

2.1 Functional Value

2.2 Typical Application Scenarios

- Engine crankshaft:Converting reciprocating motion of pistons to rotational motion of crankshaft

- Camshaft:Controlling valve opening and closing timing

- Eccentric bearing:Used in suspension systems and transmission mechanisms

- Eccentric wheel:Transmission components for various automation equipment

- Cam mechanism:Achieving complex motion trajectories

- Eccentric fixture:Tooling for quickly clamping workpieces

- Valve components:Special valve structures for fluid control

- Pump body parts:Core components of various types of pumps

- Vibration equipment:Vibrating screens, feeders, etc.

Chapter 3: Core Technology – How to Implement Eccentric Turning?

3.1 Four-Jaw Independent Chuck Clamping Method

- Precisely mark lines on the workpiece to determine the eccentric circle and cross lines

- Mount the workpiece in a four-jaw chuck

- Use a dial indicator to adjust each jaw individually to align the eccentric axis with the spindle axis

- Repeatedly check and adjust until precision requirements are met

- Strong versatility, suitable for workpieces of various shapes

- Large adjustment range, can achieve large eccentric distances

- No need for special tooling

- Extremely time-consuming alignment process, low efficiency

- Extremely high skill requirements for operators

- Precision difficult to guarantee, poor consistency

- High labor intensity

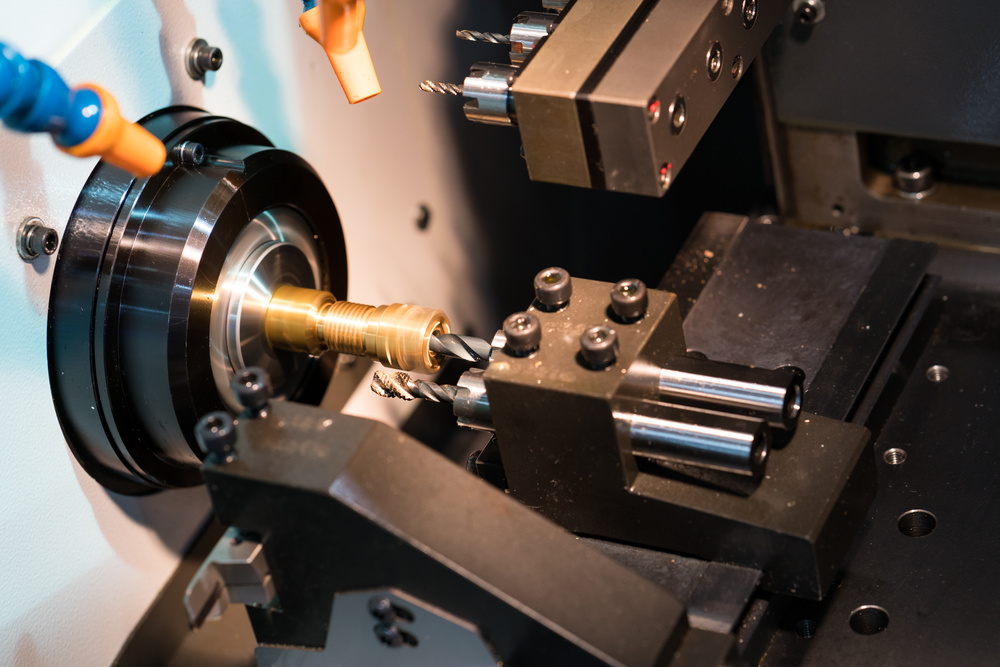

3.2 Three-Jaw Chuck with Eccentric Shims/Sleeves Method

- X = Shim thickness

- e = Workpiece eccentricity

- d = Diameter of the part clamped by three jaws

- K = Correction coefficient, adjusted according to actual conditions

- Simple operation, high efficiency

- Once shims are made, quick batch production is possible

- Relatively stable precision

- Lower cost

- Need to customize special tooling for different workpieces and eccentric distances

- Significant initial preparation work

- Limited adjustment range for eccentric distance

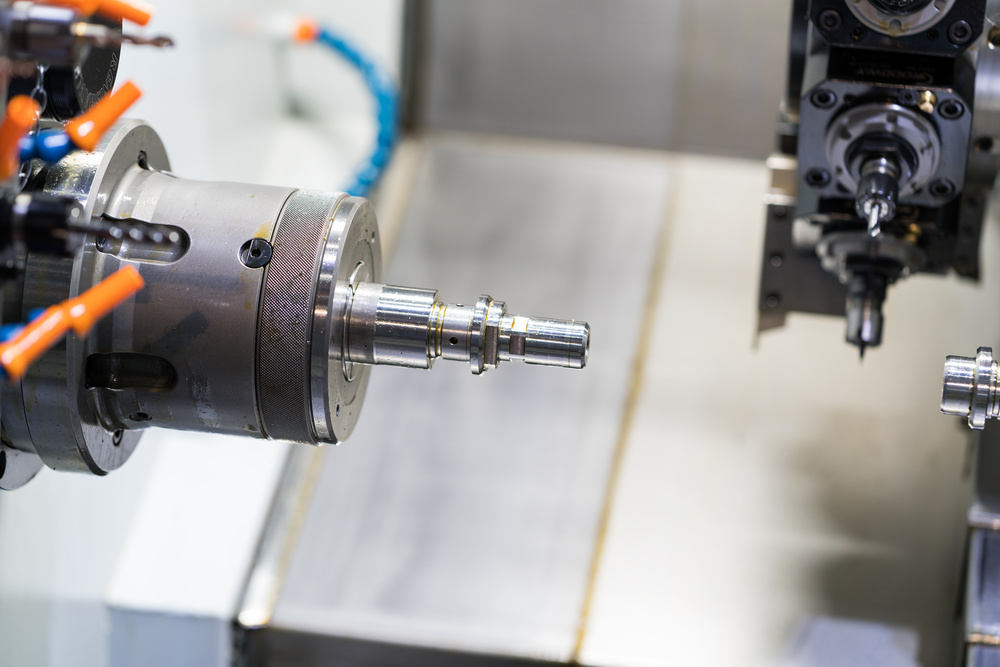

3.3 Dual-Spindle Turning Center Secondary Clamping Method

- Spindle 1 machines the reference part and clamping part of the workpiece

- Sub-spindle moves to the set eccentric position

- Sub-spindle grabs and clamps the workpiece

- Spindle 1 releases, sub-spindle drives the workpiece to rotate eccentrically

- Tool machines the eccentric part

- Complete all machining in one clamping

- Extremely high precision, good consistency

- Highest automation level

- Can machine complex multi-eccentric parts

- Huge equipment investment

- High programming requirements

- High maintenance costs

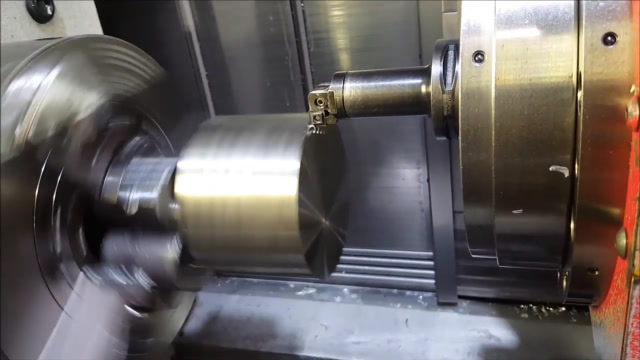

3.4 Turn-Mill Compound Programming Method

- Use G68 coordinate system rotation command

- Utilize polar coordinate programming (G15/G16)

- C-axis positioning and contour control

- Live tool turret milling function

- No need for special tooling, extremely high flexibility

- Very suitable for complex multi-eccentric parts

- Convenient programming adjustments

- Can achieve high-precision machining

- High requirements for programming and machine tool functions

- Requires turn-mill compound center equipment

- Relatively low machining efficiency

3.5 Comparative Analysis of Four Methods

|

Method

|

Precision Level

|

Efficiency

|

Cost

|

Applicable Batch

|

Eccentricity Range

|

Equipment Requirement

|

|

Four-Jaw Chuck

|

±0.02-0.05mm

|

Low

|

Low

|

Single piece small batch

|

Large

|

Ordinary lathe

|

|

Shim/Sleeve

|

±0.01-0.03mm

|

Medium

|

Medium

|

Small to medium batch

|

Small

|

Ordinary lathe

|

|

Dual-Spindle

|

±0.005-0.01mm

|

High

|

High

|

Large batch

|

Medium

|

Dual-spindle turning center

|

|

Programming

|

±0.003-0.008mm

|

Medium

|

High

|

Small to medium batch

|

Medium

|

Turn-mill compound center

|

Chapter 4: Practical Guide – Challenges and Solutions in Eccentric Turning

4.1 Core Challenge: Imbalance and Vibration

- Install counterweight blocks at symmetrical positions of the workpiece

- Counterweight mass = eccentric mass × eccentric distance / counterweight distance

- Suitable for single piece small batch production

- Reduce spindle speed to safe range

- Calculation formula: n ≤ 1200 / √e (n is rotational speed r/min, e is eccentricity mm)

- Most direct and effective method, but affects efficiency

- Use tailstock center to support the workpiece

- For long shaft eccentric parts, tailstock support is essential

- Improve system rigidity and reduce vibration

4.2 Tool and Cutting Parameter Optimization

- Material:Choose carbide with good toughness, such as WC-Co alloy

- Coating:TiAlN or AlCrN coating to improve wear resistance

- Groove type:Choose chip breaker groove suitable for stainless steel and alloy steel

- Tool nose radius:Appropriately increase tool nose radius to improve strength

- Cutting speed:30-50% lower than conventional turning

- Feed rate:Use moderate feed to avoid vibration

- Cutting depth:Layered cutting, 0.1-0.3mm per layer

- Cooling:Adequate cooling, use high-pressure coolant

4.3 Measurement and Inspection Techniques

- Mount the workpiece between centers

- Dial indicator contact touches the eccentric outer circle

- Rotate the workpiece, the difference between maximum and minimum dial indicator readings equals 2e

- Simple and intuitive, suitable for small eccentric distances

- Place the workpiece on equal-height V-blocks

- Use dial indicator to find the highest point

- Calculate eccentricity through calculation

- Suitable for workpieces with large eccentric distances

- Use CMM for precise measurement

- Can measure complex 3D eccentricity

- Highest precision but also highest cost

4.4 Common Problems and Solutions

- Causes:Excessive speed, insufficient rigidity, tool wear

- Solutions:Reduce speed, increase support, replace tools

- Causes:Insufficient clamping force, thermal deformation, tool wear

- Solutions:Increase clamping force, adequate cooling, regular tool changes

- Causes:Improper cutting parameters, wrong tool selection, insufficient cooling

- Solutions:Optimize parameters, select appropriate tools, strengthen cooling

- Causes:Conservative parameters, unreasonable process, equipment limitations

- Solutions:Reasonably optimize parameters, improve processes, upgrade equipment

Chapter 5: Industry Application Case Analysis

5.1 Automotive Engine Crankshaft Machining

- Multi-throw eccentricity, high angle precision requirements

- Strict balance requirements

- Material is high-strength alloy steel

- Use special crankshaft lathes

- Adopt dual-spindle machining technology

- Equip with automatic balancing system

- Online inspection and compensation

- Eccentricity precision: ±0.005mm

- Angle precision: ±15″

- Surface roughness: Ra0.8μm

5.2 Industrial Eccentric Cam Machining

- Complex cam profiles

- High precision requirements

- High material hardness

- Use turn-mill compound centers

- Adopt C-axis contour milling

- High-precision tooling system

5.3 Medical Device Eccentric Shaft Machining

- Materials are titanium alloy or stainless steel

- High surface finish requirements

- Biocompatibility requirements

- Special fixture design

- High-precision machining centers

- Electrolytic polishing treatment

Chapter 6: Future Development Trends

6.1 Technology Development Directions

- AI-driven parameter optimization

- Adaptive vibration control

- Predictive maintenance

- Nanoscale precision control

- Real-time error compensation

- Online inspection technology

- Energy-saving machining processes

- Environmentally friendly cutting fluids

- Waste recycling and utilization

6.2 Equipment Development Trends

- Turn-mill-grind compound machining

- Combination of 3D printing and CNC

- Integrated online measurement

- Robot loading and unloading

- Flexible manufacturing systems

- Digital twin technology

Conclusion: Mastering Eccentric Turning, Opening New Manufacturing Possibilities

- Basic understanding:Understand the concept and function of eccentricity

- Method selection:Choose appropriate machining methods based on batch size, precision, and cost

- Problem solving:Master vibration control and parameter optimization techniques

- Quality assurance:Establish a complete measurement and inspection system

- Start with small batches:Practice with simple parts first to accumulate experience

- Invest in appropriate equipment:Choose equipment configuration based on actual needs

- Cultivate professional talents:Strengthen technical training to improve operational skills

- Establish standard processes:Develop standardized technical documents