In the field of precision machining in modern manufacturing, Electrical Discharge Machining (EDM) has become an indispensable key technology due to its unique processing method and significant advantages. Emerging in the 1960s, and with the introduction of the first wire-cut EDM machine by the Soviet Union in 1967, this technology has continuously evolved and innovated, playing a crucial role in various industries.

I. Core Principles and Key Components of EDM

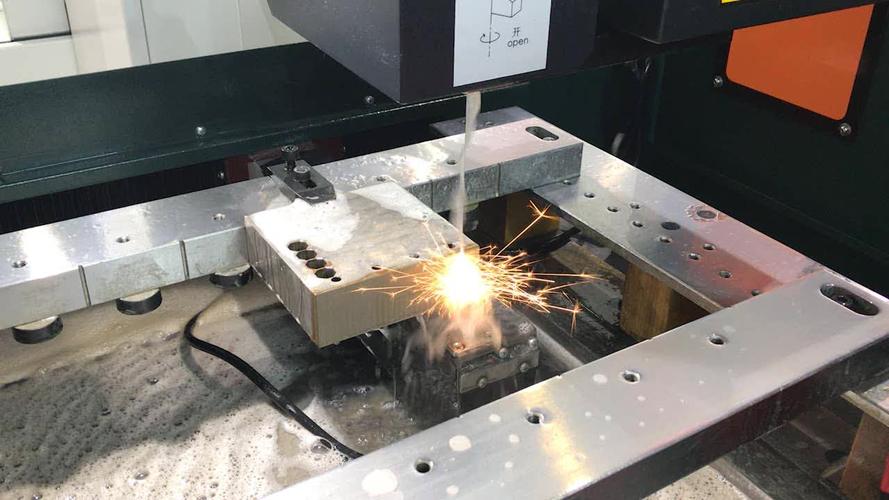

EDM is a non-contact machining technology based on the principle of electroerosion. During the machining process, a soft electrode made of materials such as graphite generates sparks between the electrode and the target area. The temperature of these sparks can reach 14,500 – 21,500°F, instantly vaporizing or cutting parts of the workpiece surface. Meanwhile, a dielectric fluid (such as non-conductive lubricating oil or deionized water) promptly removes the vaporized material from the machining area. This process repeats until the part is fully machined.

The EDM system comprises several key components, each playing an irreplaceable role. The power supply provides electricity for the entire system and supplies the sparks needed to erode the workpiece by precisely adjusting voltage, current, and frequency. Electrodes, made of highly conductive materials, maintain a specific gap with the workpiece to generate sparks, and different machining requirements necessitate the selection of appropriate electrode materials and shapes. The dielectric system not only cools the system but also effectively removes machining debris, preventing particles from adhering to the electrodes and maintaining the circulation of the dielectric fluid to ensure machining stability. The servo control system is responsible for accurately managing the gap between the electrode and the workpiece to optimize spark generation efficiency. The control panel serves as the “command center” of the entire machining process, ensuring cutting accuracy through precise management of part movement and discharge timing.

II. Three Main Types of EDM and Their Characteristics

(A) Die-sinking EDM

Also known as “ram” or “cavity” EDM, this machining method uses a 2D electrode with a complex 3D shape at the end. During machining, the electrode moves up and down in the Z-axis direction to clear the debris generated during the process. The workpiece is gradually machined through repeated arc erosion. This method is particularly suitable for machining complex cavities in hard materials, effectively reducing the need for post-processing, and is especially suitable for manufacturing molds with structures such as deep ribs and sharp internal corners.

(B) Wire EDM

Wire EDM uses a thin metal wire with a diameter of only 0.05 – 0.35mm as the “cutting tool,” corroding the material through the sparks generated between the wire and the workpiece. With the development of technology, wire EDM has evolved from simple 2D cutting (moving only in the X and Y axes) to advanced 5-axis machining. Complex machining operations such as inclined cutting are achieved through techniques like offsetting the guide wheels and adding rotating axes. However, wire EDM has certain limitations. It can only machine through holes and requires pre-drilling to thread the wire, making it unsuitable for blind holes. Nevertheless, it is widely used in the manufacturing of automotive and aerospace parts (such as stamping dies and extrusion dies) and the production of medical and dental equipment.

(C) Hole-drilling EDM

The advantage of hole-drilling EDM lies in its ability to machine small, straight holes with a high length-to-diameter ratio, with the minimum drillable hole diameter reaching 0.0015 inches. This machining method can maintain extremely high hole size accuracy and is commonly used for machining starting holes for wire threading in wire EDM, removing broken taps, and processing special parts such as cooling channels in turbine blades. The surface finish of the machined holes is extremely high, and they can even be directly used as bearing surfaces.

III. Applicable Scenarios and Material Range of EDM

EDM is suitable for various complex machining scenarios. For parts with complex structures, such as 3D cavities, sharp internal corners, deep holes, and small holes, traditional machining methods often fall short, while EDM can handle them with ease. When machining hard materials with high processing difficulty, such as tungsten and nickel, the non-contact machining characteristic of EDM makes it an ideal choice. For parts requiring high precision, since EDM does not need to apply tension to the workpiece, it can achieve high-precision hole formation in one step, and is widely used in industries with strict precision requirements, such as aerospace and medical.

In terms of material range, EDM is applicable to most conductive materials. Brass, due to its excellent electrical conductivity and machinability, is widely used in EDM machining. Whether in wire cutting, die-sinking, or hole drilling, it can achieve smooth surfaces and precise cuts. The light weight and good thermal conductivity of aluminum make it advantageous in wire cutting and die-sinking EDM, facilitating heat dissipation during machining. Steel materials pose many difficulties in traditional machining, but EDM can precisely machine molds and complex parts. Copper, with its good electrical conductivity and ductility, is used in EDM machining for precise cutting and mold forming. Nickel materials are difficult to process traditionally due to their high temperature resistance and corrosion resistance, but EDM can be used for wire cutting and die-sinking to machine precision parts. Tungsten’s high melting point and hardness make traditional machining challenging, and EDM demonstrates unique value in the die-sinking machining of wear-resistant molds and parts.

IV. Analysis of the Advantages and Disadvantages of EDM

(A) Significant Advantages

EDM excels in design flexibility, capable of machining hard materials and complex shapes that are difficult to handle with traditional methods. Its non-contact machining feature avoids mechanical deformation, effectively protecting parts with fragile structures. Its high-precision machining capability makes it the first choice for manufacturing high-tolerance parts in industries such as aerospace and automotive. The good surface finish reduces post-processing steps, improving production efficiency.

(B) Existing Limitations

However, EDM also has some limitations. Its material compatibility is limited, only applicable to conductive materials, and the heat generated during machining may change the metal properties. The material removal rate is relatively slow, making it unsuitable for large-scale production. In die-sinking machining, the cost of custom electrodes is high, increasing the cost of small-batch production. Additionally, EDM machining consumes a large amount of energy, resulting in high power consumption and a relatively high carbon footprint.

V. Typical Application Examples of EDM in Various Industries

In the medical industry, due to the extremely high precision requirements for parts, where any deviation may affect the performance of the equipment and the health of patients, EDM is widely used in the manufacturing of medical devices such as cochlear implants, pacemakers, dental implants, and dental crowns. In the aerospace field, where the dimensional accuracy of complex parts is crucial, EDM is used to machine key components such as stator blades, turbine disks, landing gear parts, and fuel system parts. In the manufacturing industry, EDM meets the requirements of precision machining and is commonly used for machining parts such as plastic molds, extrusion dies, gears, and threads. In the electronics industry, since EDM can only machine conductive metals and the requirements for the mating accuracy of electronic parts are extremely high, it is used for manufacturing parts such as connectors, sensors, switches, and electrodes.

VI. Cost Considerations of EDM

When considering using EDM machining, cost is an important factor. In terms of equipment investment, the initial cost of EDM equipment is relatively high, especially for advanced models, which makes it difficult to control the cost of small-batch production. Operating costs include the consumption of consumables such as electrodes, wires, and dielectric fluids, as well as power consumption, all of which increase the overall cost. Although EDM machining generates less waste, and the material cost is relatively lower than traditional machining, in terms of maintenance, regular equipment maintenance is required to ensure machining accuracy, and the maintenance frequency and cost also affect the total cost. Regarding labor costs, EDM machining requires skilled operators, and the technical complexity directly affects the salary level. Although a single EDM setup can machine complex parts, improving efficiency to some extent, the overall machining speed is slower than CNC. However, the tool wear rate during EDM machining is low, giving it an advantage in tool replacement and maintenance costs.

VII. Key Points for Selecting EDM Services

When enterprises need to select EDM services, there are several key points to consider. First, the experience and technical level of the supplier are crucial. Suppliers with multiple technologies such as die-sinking, wire cutting, and hole drilling can better meet diverse machining requirements. Second, according to the size and complexity of the project, select a supplier whose equipment capabilities match. Finally, good communication and a reasonable delivery cycle are also important considerations to ensure timely product delivery. Meanwhile, compare the prices and turnaround times of different suppliers to achieve a balance between cost and efficiency.

In conclusion, Electrical Discharge Machining (EDM), as a revolutionary technology in the field of precision machining, occupies an important position in modern manufacturing. Despite some limitations, with the continuous development and innovation of technology, the application scope of EDM will continue to expand, bringing efficient and precise machining solutions to more industries.