Material Selection and Performance Characteristics

The choice of materials is critical in automotive customization, as it directly impacts performance, durability, and aesthetics. European manufacturers utilize a sophisticated selection of advanced materials to meet the exacting requirements of discerning customers.

Carbon Fiber Composites

- Tensile strength: 3,600 MPa (5x stronger than steel)

- Density: 1.55 g/cm³ (30% lighter than aluminum)

- Modulus of elasticity: 230 GPa (excellent stiffness-to-weight ratio)

- Applications: Body panels, interior trim, performance components

Aluminum Alloys

- 6061-T6: Yield strength 276 MPa, excellent machinability

- 7075-T6: Tensile strength 572 MPa, high strength-to-weight ratio

- 5052-H32: Excellent corrosion resistance, formability

- Applications: Structural components, suspension parts, wheels

High-Strength Steels

- 4130 Chromoly: Tensile strength 970 MPa, weldable

- 4340 Alloy Steel: Yield strength 745 MPa, heat treatable

- Docol 1200M: Ultra-high strength for safety components

- Applications: Roll cages, suspension arms, drive shafts

Titanium Alloys

- Ti-6Al-4V: Tensile strength 900 MPa, corrosion resistant

- Density: 4.51 g/cm³ (40% lighter than steel)

- Temperature resistance: Up to 400°C

- Applications: Exhaust systems, high-performance fasteners

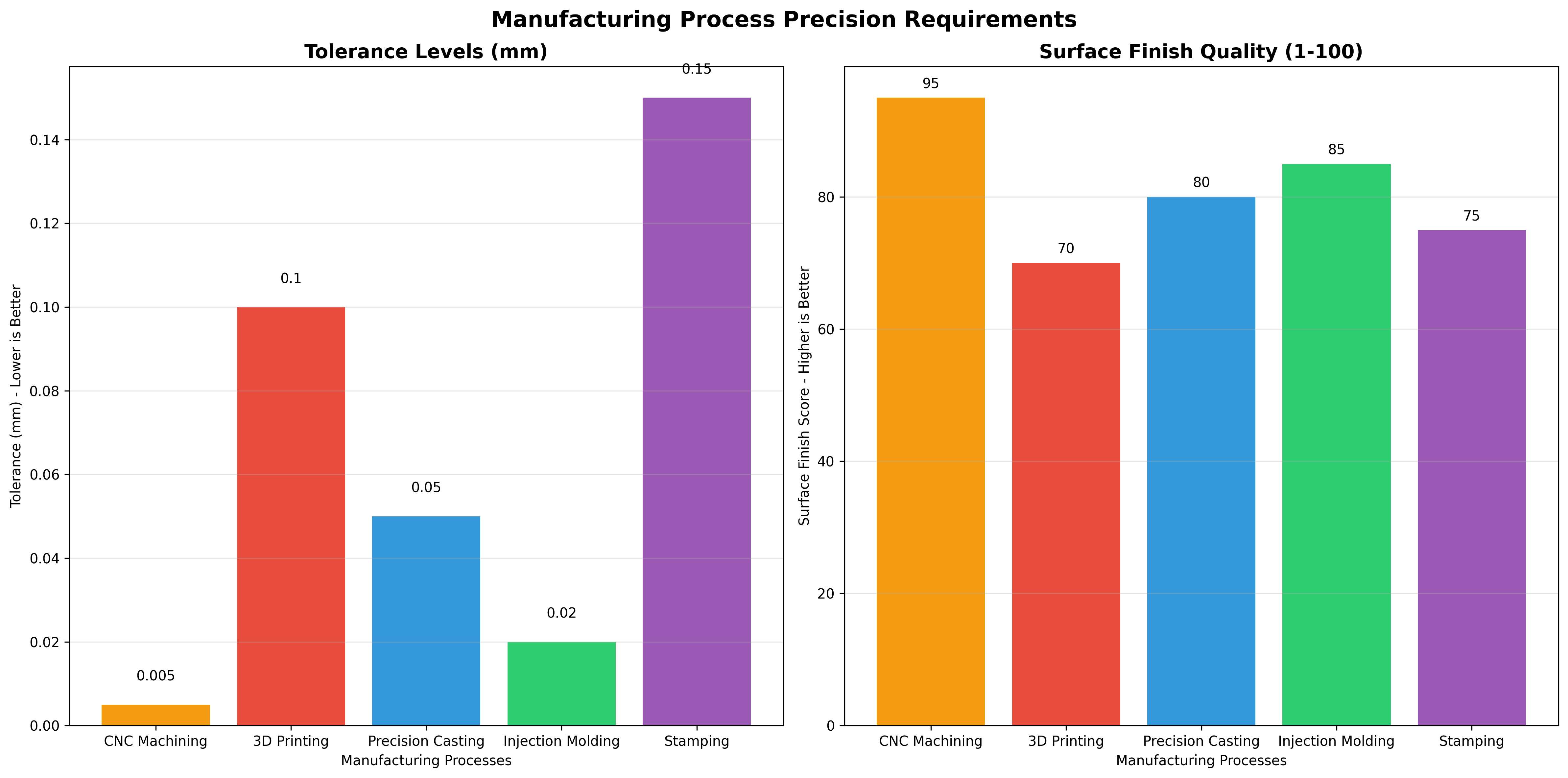

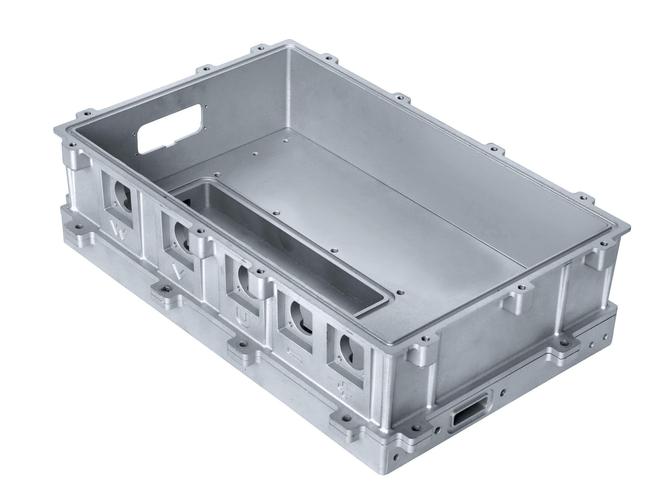

Advanced Manufacturing Processes

European automotive customization relies on state-of-the-art manufacturing technologies to achieve the highest levels of precision and quality.

CNC Machining Excellence

- Multi-axis capabilities: 5-axis simultaneous machining for complex geometries

- Tolerance levels: ±0.005mm (5 microns) for critical components

- Surface finish: Ra 0.4 μm (mirror-like quality)

- Materials processed: Aluminum, steel, titanium, composites

3D Printing Technologies

- SLS (Selective Laser Sintering): For high-strength plastic components

- SLM (Selective Laser Melting): For metal parts with complex internal structures

- FDM (Fused Deposition Modeling): For rapid prototyping and tooling

- Layer resolution: 25-100 μm for precise details

Precision Casting

- Investment casting: Dimensional accuracy of ±0.1mm for intricate parts

- Sand casting: Cost-effective for larger components with complex shapes

- Die casting: High-volume production with tight tolerances

- Heat treatment: T6, T7, and H112 processes for optimal material properties

Injection Molding

- High-precision molds: ±0.02mm tolerance for plastic components

- Material compatibility: Engineering plastics, elastomers, composites

- Cycle times: 30-90 seconds for efficient production

- Surface finishes: Textured, painted, or chrome-plated options