Yes, it can! An end mill can not only make a cube, but it can make it very precisely!

Today I want to show you an amazing “metal transformation magic show”! Imagine this: a plain metal block turns into a perfect cube right before your eyes, just like magic, with the help of an end mill – the “metal carving master”. Isn’t that cool?

Want to know how this metal magic works? Want to see how an end mill “draws” on metal like a little artist? Then join me as we explore this amazing mechanical world!

What is an End Mill?

Before we start our exploration, let me tell you what an end mill is.

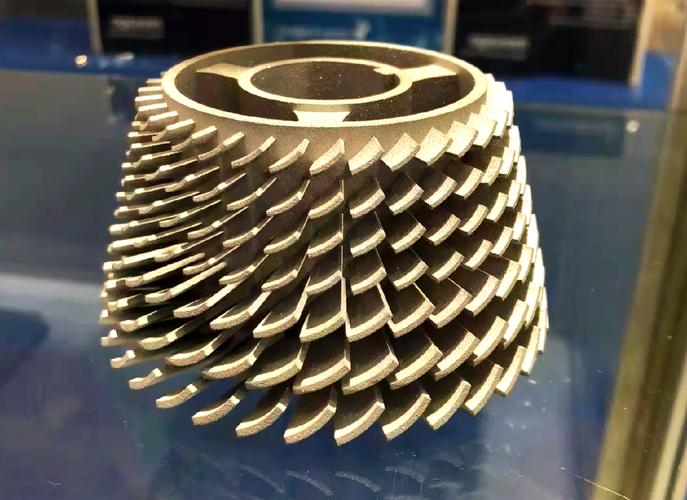

An end mill is a magical tool. It looks like a metal “little spiral”. It has many sharp cutting edges and can spin very fast, just like a small “metal carver”.

Look, this is what an end mill looks like! Its cutting edges are spiral-shaped. This design makes it spin more steadily and helps it “eat” metal better.

How Does an End Mill Work?

The working principle of an end mill is actually quite simple. It’s like when we draw on paper with a pencil, but instead of paper, it draws on metal!

- Spins very fast: The end mill attaches to the machine’s spindle and spins thousands of times per minute

- Moves precisely: The machine controls the end mill to move accurately in three directions: X, Y, and Z

- Cuts metal: When the spinning cutting edges touch the metal, they “bite” off extra metal like “little teeth”

- Shapes the metal: By controlling the movement path, we can make any shape we want

So, Can an End Mill Make a Cube?

Now back to our question: Can an end mill make a cube?

My answer is: Yes, it can!

Look at this picture – workers are using an end mill to make a cube!

How an End Mill Makes a Cube

There are actually a few ways an end mill makes a cube:

- Start with a big block: First, prepare a metal block that’s bigger than the cube we want to make

- Machine one face at a time: Use the end mill to machine each of the cube’s six faces one by one

- Control dimensions precisely: After machining each face, measure the dimensions to make sure all six faces of the cube are exactly the same size

Why Can an End Mill Make a Cube?

An end mill can make a cube because it has some special abilities:

- Flat surface machining: The bottom of the end mill has sharp cutting edges, like a “little shovel” that can flatten metal surfaces

- Side machining: The sides of the end mill also have cutting edges, so it can machine the cube’s sides

- Precise control: Modern CNC machines can control the end mill’s movement very accurately, with errors smaller than a human hair

Steps to Make a Cube with an End Mill

Let me show you the detailed steps to make a cube with an end mill:

Step 1: Prepare Materials

First, we need to prepare a metal material, usually aluminum or iron. This material should be bigger than the cube we want to make, so there’s enough material to work with.

Step 2: Secure the Workpiece

Fix the metal block firmly to the machine’s worktable, just like when we fix paper to a table before drawing.

Step 3: Install the End Mill

Choose the right end mill and install it on the machine’s spindle. Different materials need different types of end mills.

Step 4: Start Machining

This is the most important step! The machine follows a pre-programmed sequence, controlling the end mill to “chew” away extra metal bit by bit.

Step 5: Check and Adjust

After machining each face, carefully check if the dimensions are accurate, then machine the next face.

Types of End Mills

There are many types of end mills, just like we have different paintbrushes for painting:

- Square end mill: The most commonly used, good for machining flat surfaces and sides

- Ball nose end mill: Has a rounded tip, good for machining curved surfaces

- Corner radius end mill: Has rounded corners, so the edges it makes aren’t too sharp

Safety Precautions

Although end mills are amazing, we must always be careful when using them:

- Wear safety glasses: To protect eyes from flying metal chips

- Keep distance: Don’t get too close to the working end mill

- Professional operation: End mills need professional workers to operate them

- Regular checks: Always check if the end mill is sharp and not damaged

My Discoveries

Through this exploration, I discovered that end mills are truly amazing tools! They can not only make cubes, but also many complex shapes like car parts, airplane parts, and even the phone cases we use.

What surprised me most is that modern end mills can machine parts with extremely high precision – errors as small as 0.001 millimeters, thinner than a human hair!

Conclusion

After my exploration, I can definitely answer: “End mills can not only make cubes, but they can make them very precisely!”

An end mill is like a magical “metal carver”. It shows us that with the right tools and methods, we can turn ordinary metal blocks into all kinds of useful parts.

I believe that with the development of technology, end mills will become more and more advanced, able to machine more shapes we can’t even imagine!