In today’s rapid development of technology, 3D printing technology is like a dazzling new star, lighting up the road of manufacturing innovation. Among them, 3D metal printing service has become the focus of attention of many industries by virtue of its unique advantages and broad application prospects.

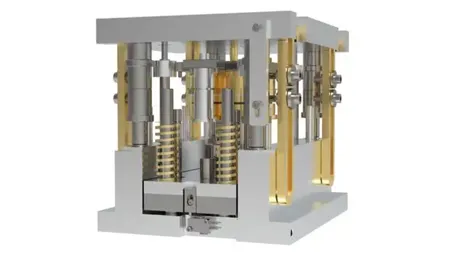

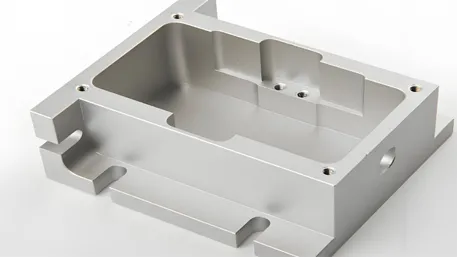

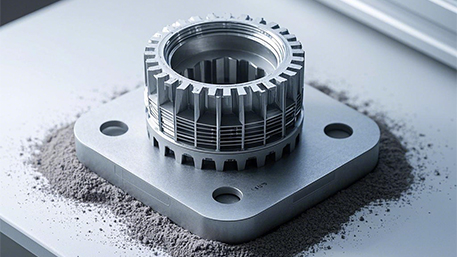

Traditional metal processing is often plagued by problems such as mold making, difficulty in processing complex shapes, and material waste. 3D metal printing is very different, it is based on the principle of additive manufacturing, based on the digital model, through the layer-by-layer stacking of metal powder or wire way, directly build a complex three-dimensional metal parts. This unique manufacturing method greatly frees up design, making complex geometries that were previously considered difficult or even impossible to machine a reality.

In the aerospace sector, 3D metal printing services have revolutionized the manufacture of aircraft. For example, some components in engines with complex internal cooling channels can be molded in one piece using 3D metal printing. These complex channel structures can effectively improve cooling efficiency while reducing component weight, which is critical to improving vehicle performance and fuel efficiency. Furthermore, in the development of aerospace components, 3D metal printing enables rapid prototyping, significantly shortening the development cycle and accelerating the introduction of new models.

The medical industry is also a beneficiary of 3D metal printing services. Customized metal implants, such as hip and knee prostheses, can be precisely designed and manufactured according to a patient’s individual anatomy. Doctors can construct an accurate model from a patient’s CT or MRI data, and then create implants that perfectly match the patient’s bones with the help of 3D metal printing technology, which not only improves the success rate of surgery, but also significantly improves the patient’s quality of life after surgery. In addition, in the dental field, 3D metal printing is used to create crowns, bridges and other restorations, and its high precision and good biocompatibility have been widely recognized.

The automobile manufacturing industry is also actively exploring the application of 3D metal printing. Some high-performance racing teams use 3D metal printing to manufacture lightweight engine parts, suspension components, etc. While enhancing vehicle performance, they can also reduce the number of parts through optimized design and improve overall reliability and maintainability. For mass-produced vehicles, 3D metal printing can be used to produce small-lot, customized parts, such as special decorative parts or parts with unique functions, to meet the increasingly diversified needs of consumers.

However, 3D metal printing services are not always easy. The selection and handling of metal materials require specialized knowledge and experience, and different metal powders differ in melting point, fluidity, sintering characteristics, etc., which puts high demands on the parameter settings of the printing process. Moreover, 3D metal printing equipment is costly and complicated to maintain, requiring specialized technicians to operate and manage. In addition, post-processing procedures after printing, such as heat treatment and surface finishing, will also affect the quality and performance of the final product.

Despite the many challenges, as technology continues to advance, the cost of 3D metal printing services is gradually decreasing, and printing speed and accuracy continue to improve. New metal materials are also being developed and applied, expanding their possibilities in more areas. It is foreseeable that 3D metal printing services will continue to play an important role in the manufacturing industry in the future, driving various industries in the direction of more personalization, efficiency and innovation. Whether it is high-end manufacturing in pursuit of extreme performance or niche markets focusing on personalization, 3D metal printing will become an indispensable key technology, creating a new manufacturing future full of infinite possibilities for us.