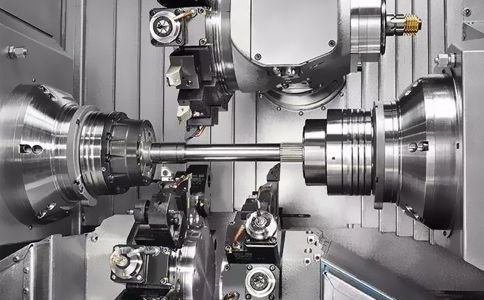

In the world of CNC machining, two processes stand out for shaping metal and plastic parts: face milling and end milling. While both use rotating cutting tools to remove material, they excel in different tasks—one focuses on creating flat surfaces, the other on intricate shapes and details. At Goldcattle, with 26 years of CNC milling expertise, we know that choosing between face milling and end milling can make or break your project’s efficiency, precision, and cost. Let’s break down their differences, applications, and how to pick the right one for your needs.

Tool Design: How Face Mills and End Mills Differ

The first clue to their roles lies in their tool designs.

Face milling tools are flat, disc-shaped cutters with multiple carbide inserts mounted on their periphery and face. They’re built for covering large areas: diameters range from 25mm to 300mm, with 4–12 cutting edges to distribute wear evenly . The inserts have a large rake angle to reduce cutting forces, making them ideal for fast material removal.

End milling tools, by contrast, are cylindrical with cutting edges on their tip (end) and sides (flutes). They’re more compact, with diameters from 3mm to 50mm, and 2–4 flutes for chip evacuation . Their pointed or square tips let them plunge into material and carve complex geometries.

At Goldcattle, we stock a range of both: from 100mm diameter face mills for steel plates to 6mm carbide end mills for aluminum prototypes.

Primary Purpose: What Each Process Does Best

Face Milling: Master of Flat Surfaces

Face milling’s claim to fame is creating large, smooth flat surfaces—think of it as “planing” a workpiece. It’s used to:

Square off the top of a raw material block (e.g., turning a rough steel billet into a flat plate).

Create precision flange faces or mounting surfaces that need tight flatness tolerances (±0.01mm/100mm).

Reduce material thickness uniformly (removing 1–5mm per pass on aluminum, 0.5–2mm on hardened steel) .

A recent project for an automotive client saw us use face milling to finish 2m x 1m steel engine blocks, achieving a surface roughness of Ra 1.6μm—critical for proper gasket sealing.

End Milling: Champion of Shapes and Details

End milling is the go-to for 3D contours, slots, and intricate features. It excels at:

Cutting slots, grooves, and pockets (e.g., creating channels for wiring in a metal housing).

Profiling edges or creating 3D shapes (like curved aerospace brackets).

Plunging into material to start a cut, then moving horizontally to carve details .

For a medical device client, we used a 10mm 4-flute end mill to machine a 0.5mm-deep pocket in titanium, with a surface finish of Ra 0.8μm—perfect for housing a tiny sensor.

Speed and Efficiency: Which Gets the Job Done Faster?

When it comes to large flat surfaces, face milling is unbeatable. Its multiple cutting edges and high feed rates (1000–3000mm/min on aluminum) mean it can cover 100cm² in under a minute—5–10x faster than end milling for the same area .

End milling, however, shines in precision over speed. Its slower feed rates (300–1500mm/min) allow for tighter control, making it better for detailed work where accuracy matters more than raw speed. For example, cutting a 50mm slot with 0.02mm tolerance takes end milling 2 minutes, but face milling couldn’t do it at all.

Goldcattle optimizes both: our 5-axis CNC mills adjust feed rates dynamically, using face milling for flat sections and switching to end milling for details in the same program—saving clients up to 20% in cycle time.

Material Compatibility: Which Works Best for Your Material?

Both processes handle metals (aluminum, steel, titanium) and plastics (PEEK, nylon), but their strengths vary by material:

Aluminum (6061): Face milling thrives here, with high speeds (3000–6000 RPM) and minimal tool wear. End milling works too but needs slower feeds to avoid melting.

Stainless Steel (316): Face mills with coated carbide inserts (TiAlN) handle the toughness, while end mills need sharp edges and coolant to prevent work hardening .

Titanium (Grade 5): End milling is preferred for details, using low speeds (500–1000 RPM) and high coolant flow. Face milling works but requires heavy-duty inserts.

Plastics: End milling with 2-flute tools reduces heat buildup, while face milling needs light passes to avoid chipping.

Our material experts at Goldcattle recently helped a robotics client switch from end milling to face milling for their aluminum base plates, cutting production time by 40% without sacrificing flatness.

Precision and Finish: How They Compare in Quality

Flatness: Face milling delivers superior flatness (±0.005mm/100mm) thanks to its large contact area and rigid setup. End milling can achieve flatness but struggles with larger surfaces due to tool deflection.

Surface Roughness: Face milling with fine inserts hits Ra 0.8–3.2μm, while end milling ranges from Ra 0.4μm (with sharp tools) to Ra 6.3μm (for roughing) .

Tolerances: Both hit ±0.01mm, but end milling excels at positional tolerances (e.g., hole-to-hole spacing) due to its precise tool paths.

Goldcattle uses in-process probing and CMM inspection to verify: face milled surfaces on a recent aerospace part measured ±0.003mm flatness, while end milled slots hit ±0.005mm width—meeting AS9100 standards.

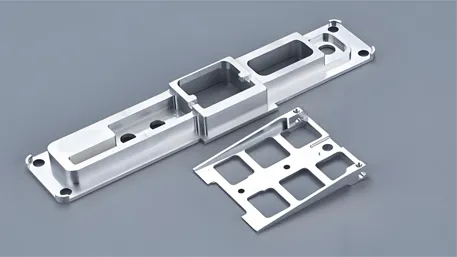

When to Combine Both: The Power of Hybrid Milling

Most projects don’t choose between face milling and end milling—they use both. A typical workflow might:

Face mill the raw material to create a flat, uniform base.

End mill slots, holes, or contours into that base.

Face mill again to clean up any burrs from end milling.

For a consumer electronics client’s laptop chassis, we face milled the aluminum frame (achieving flatness), then end milled the keyboard cutout and port holes (adding details)—delivering 10,000 units with 99.9% dimensional accuracy.

FAQs: Face Milling vs End Milling

Q: Can I use an end mill for face milling small surfaces?

A: Yes! For areas under 50mm, a square-end mill can face mill, but it’s slower than a dedicated face mill. We recommend it for prototypes or small batches.

Q: Which is more cost-effective for large parts?

A: Face milling—its faster material removal reduces machine time, lowering costs by 15–30% for large flat components like steel plates .

Q: Do they require different CNC machines?

A: No—most CNC mills (3-axis, 5-axis) handle both. Goldcattle’s HAAS and FANUC machines switch seamlessly between face and end milling programs.

Q: How do tool costs compare?

A: Face mill inserts are cheaper to replace than solid carbide end mills, but face mill bodies have a higher upfront cost. For high-volume runs, face milling is more cost-efficient.

Q: When should I choose end milling over face milling?

A: For 3D shapes, slots, pockets, or small precision features—anywhere flatness isn’t the primary goal.

Ready to Choose the Right Milling Technique?

Face milling and end milling aren’t rivals—they’re partners in creating precision parts. Whether you need a flat steel plate or an intricate aluminum bracket, Goldcattle’s CNC experts will recommend the right process (or combination) to hit your tolerances, budget, and deadline.

Visit https://www.xmgoldcattle.com/ to upload your design or request a free machining consultation. Let’s turn your blueprint into a perfect part.

Got a project that needs milling? Tell us your material and requirements below—our team will help you decide between face and end milling!