Resin silicone mold is a kind of mold product that combines the hardness of resin material and the flexibility of silicone material. It is widely used in handicrafts, crafts, home decoration, jewelry and other fields.

1.The process of making resin silicone mold

Making resin silicone molds is a delicate process that involves many steps, the following is a detailed introduction of the production process:

Preparation stage

Material preparation:

Resin model (can be ready-made or self-made).

Liquid silicone (need to choose the right viscosity and hardness according to the specific needs).

Mold releasing agent (used to help the silicone gel to release smoothly after curing).

Other tools and materials, such as clay, mold frame template, hot melt glue gun, scraper, mixing tool, vacuum pump (optional), etc.

Environment Preparation:

Ensure that the work area is clean and tidy, free from dust and debris.

Prepare the necessary ventilation facilities to avoid inhaling harmful gases during operation.

Model Handling

Clean the resin model: Make sure the surface of the resin model is clean and smooth, so that the surface of the silicone mold produced will be smoother, thus getting a finer replica.

Making mold halves:

Use clay to knead the shape that matches the resin model and punch locating holes around the perimeter to prevent deformation during the curing process of the silicone.

Other materials (e.g. plaster, putty, etc.) can also be used to make the mold halves, the choice of which depends on the process requirements and material properties.

Silicone Infusion

Mixing Silicone: Mix the A and B components of the silicone in proportion according to the instructions of the silicone. Pay attention to avoid excessive air bubbles when mixing.

Vacuum treatment (optional): Put the mixed silica gel into the vacuum box for vacuum treatment to eliminate air bubbles in the silica gel. This step is not necessary, but it can significantly improve the quality of the mold.

Filling Silicone:

Slowly pour the blended silica gel into the pre-prepared mold frame (the frame should be close to half of the mold made of clay or other materials).

Be careful to control the speed of pouring silicone to avoid air bubbles. You can use a scraper or other tools to smooth the surface of the silica gel to ensure an even distribution of the silica gel.

Curing and demolding

Waiting for curing: According to the instructions of the silicone gel, wait for a certain period of time for the silicone gel to fully cure. The curing time depends on the type of silicone, temperature and other factors.

Removing the mold:

After the silicone has cured, carefully remove the mold frame and mold halves made of clay or other materials.

Use a tool such as a knife to cut around the silicone mold to separate the silicone from the model. Be careful to operate gently to avoid damaging the silicone mold.

Making the other half of the mold (if needed)

If you need to make a yin and yang mold, you can repeat the above steps to make the other half of the mold. Finally, combine the two halves of the mold and secure them with a rubber band or other means.

Making Resin Crafts with Molds

Mixing the resin: Mix the A and B components of the resin in proportion according to the instructions for the resin.

Pouring Resin: Slowly pour the mixed resin into the silicone mold, making sure the resin fills the entire mold and avoiding air bubbles.

Wait for curing: Wait for the resin to fully cure. The curing time depends on the type and thickness of the resin.

Release & Finish: Once the resin has cured, carefully take off the silicone mold and remove the finished resin craft.

With the above steps, a high quality resin silicone mold can be made and used to create beautiful resin crafts. During the whole production process, you need to keep patience and careful to make sure that each step is done according to the requirements.

2.Materials for making resin silicone molds

Making resin silicone molds requires a series of professional tools and materials, the following is a detailed list:

Tools

Mixing tools: Used to mix the A and B components of the silicone to ensure that they are well mixed. This can be a mixing stick, a mixing bucket or an electric mixer, etc.

Measuring tool: e.g. electronic scale, used to accurately weigh the A and B components of the silica gel to ensure accurate proportioning.

De-bubbling tool (optional): such as a vacuum pump, which is used to extract air bubbles from the mixed silica gel to improve the quality of the mold. Although this is not required, for more demanding mold making, using a vacuum pump for defoaming can significantly improve the smoothness and accuracy of the mold.

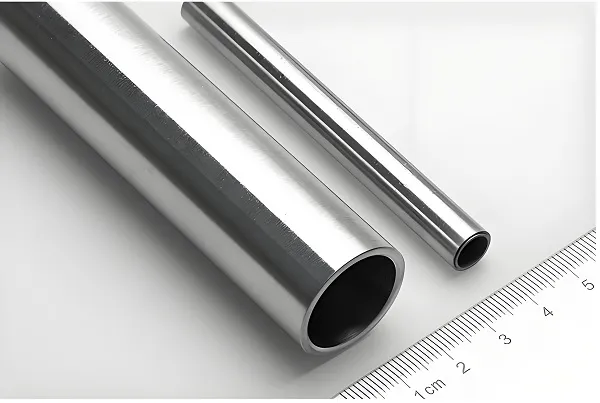

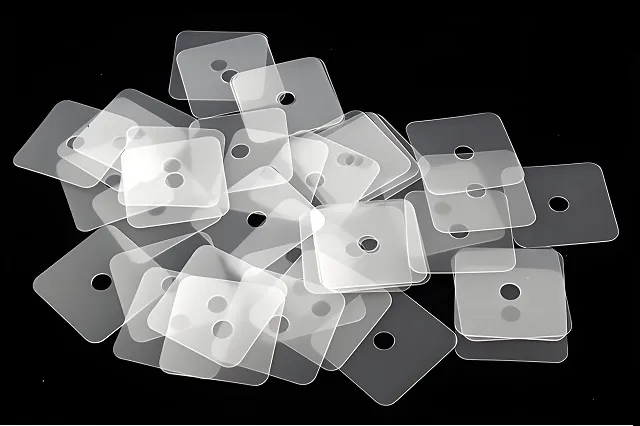

Mold Frame Template: The frame used to make the mold can be customized according to the size and shape of the resin model. The mold frame material can be chosen from acrylic board, glass and other smooth and easy to process materials.

Fixing tools: such as hot melt glue gun, glue, etc. They are used to fix the resin model and the mold frame to ensure that there will be no movement or deformation during the silicone infusion process.

Cutting tools: such as scissors, knives, etc., are used to cut the mold after the silicone has cured to separate it from the resin model.

Other auxiliary tools: such as scrapers, brushes, etc., used to scrape the surface or apply mold release agent during the silicone infusion process.

Materials

Resin material: Usually with high hardness and strength, able to maintain the shape stability of the mold, and at the same time has a certain degree of corrosion and abrasion resistance.

Silicone material: has excellent flexibility and elasticity, can be deformed when subjected to external forces but not easy to rupture, as well as good resistance to high temperatures and chemical stability.

Release agent: Used to form a layer of isolation between the silicone and the resin model, so that the silicone can be smoothly demolded after curing. Common release agents include water-based release agents, oil-based release agents, etc.

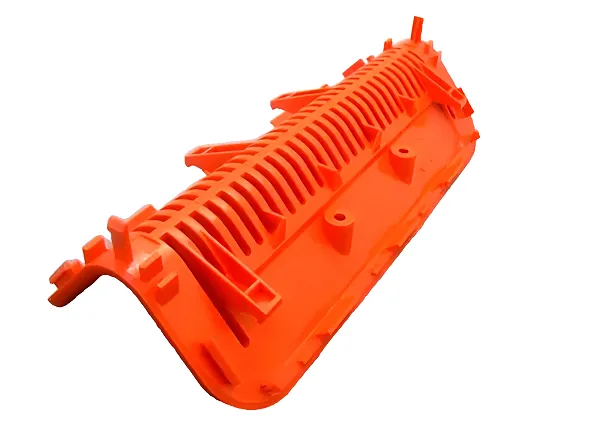

Resin model: This is the object to be reproduced, which can be ready-made or self-made. The surface of the resin model should be clean and smooth to ensure the surface quality of the silicone mold produced.

Other auxiliary materials: such as clay and plaster, which are used to make the mold halves or as support structures. In addition, some cleaning supplies, such as alcohol, wet wipes, etc., are needed for cleaning the tools and the surface of the mold.

3.Application Areas

Handicrafts production: such as drip glue jewelry, aroma candles, flipping cake and other handicrafts in the production process, resin silicone molds can easily replicate a variety of exquisite patterns and shapes.

Home decoration: resin silicone molds can produce a variety of creative and beautiful home decorations, such as ornaments, vases, photo frames and so on.

Jewelry and accessories: In the production of jewelry and accessories, resin silicone molds can be used to make pendants, rings and other jewelry models, to facilitate the subsequent casting and processing work.

Educational experiments: in the experimental teaching of chemistry, physics and other subjects, resin silicone molds can be used to produce a variety of experimental equipment and models to help students better understand and master the relevant knowledge.