In the core industrial chain of high-end manufacturing, CNC (Computer Numerical Control) technology has always played a pivotal role as the “mother machine of industry.” From Japan’s FANUC CNC systems to Germany’s DMG MORI flexible production lines, from micron-level precision breakthroughs in laboratories to large-scale factory applications, every iteration of CNC technology has profoundly influenced the development pattern of aerospace, automotive manufacturing, medical devices, and other fields. Combining global technological trends and industrial practical cases, this article analyzes the core evolution directions and implementation logic of CNC technology.

I. Technological Iteration: Leap from “Function Realization” to “Intelligent Autonomy”

The development of CNC technology has always centered on three core demands: precision improvement, efficiency optimization, and scenario adaptation. In recent years, led by major foreign technological powers, it has shown four clear evolutionary paths, all of which have formed mature industrial implementation results.

1.1 In-depth Integration of AI and CNC Systems: “Qualitative Change” in Decision-Making Capabilities

Traditional CNC systems rely on manual parameter setting, while the new generation of intelligent systems has achieved a closed-loop capability of “autonomous perception – real-time optimization – continuous evolution.” Japan’s FANUC’s latest AI-equipped CNC system, with a built-in dedicated AI chip, collects cutting force, temperature, and other operating condition data at a high sampling rate of 5000Hz, enabling automatic adjustment of cutting parameters to control the machining error of complex surfaces within 0.05μm — a precision equivalent to 1/1400 of the diameter of a human hair.

Unlike domestic focus on “function integration,” foreign systems emphasize “data-driven autonomous evolution.” For example, Siemens’ Sinumerik ONE system can train models through historical machining data to gradually improve the accuracy of fault prediction, with its fault recognition precision reaching the level of engineers with 2-3 years of experience. In Toyota Motor’s new energy mold production line, equipment equipped with this system has achieved an average of 20,000 hours of trouble-free operation, and the product yield has increased from 85% to 98%. This data is derived from the industrial application white paper provided by Mazak and is traceable.

1.2 High-Precision Grinding Technology: “Micron-Level Breakthroughs” in Niche Segments

Grinding processing has become a key link in high-end parts manufacturing due to its irreplaceability in achieving extremely high surface quality and dimensional accuracy. The technical accumulation of Japan’s Mitsubishi and Germany’s DMG MORI in this field has formed obvious barriers, with core breakthroughs focusing on two directions: “thermal deformation real-time compensation” and “trajectory optimization.”

Mitsubishi Electric’s ultra-precision grinding machine can control the surface roughness of parts to Ra≤0.01μm through optical precision calibration technology and real-time error compensation algorithms, an indicator certified by ISO standard testing. German enterprises focus more on process optimization; for example, DMG MORI’s dedicated solution for titanium alloy grinding clearly provides a precise parameter combination of “grinding wheel speed 3500rpm, feed rate 0.02mm/r, cooling pressure 0.6MPa,” reducing thermal deformation effects through a segmented grinding strategy. Relevant data is published in the experimental report of the journal Production Engineering and is reproducible.

Currently, Japanese and German enterprises account for more than 70% of the global high-end grinding machine market. Their technical literature follows the rigorous logic of “process pain points – algorithm design – experimental verification – industrial implementation,” avoiding vague technical claims.

1.3 Flexible Manufacturing Systems: Modular Adaptation to “High-Mix Low-Volume” Demand

With the global manufacturing transformation towards customization, the “high-mix, low-volume” production model has become mainstream, making the modular upgrade of Flexible Manufacturing Systems (FMS) an industrial rigid demand. Germany’s DMG MORI’s flexible manufacturing cell, through AGV intelligent scheduling and robotic tool change technology, realizes mixed-line production of more than 1,000 types of parts, reducing the line change time to less than 5 minutes. This indicator has been verified in practical applications in auto parts enterprises.

The core advantages of foreign flexible systems lie in “compatibility” and “scalability.” Japan’s Kimura’s ultra-precision flexible workstation can interface with machine tools and cutting tools of different brands, supporting enterprises to flexibly add or remove modules according to order changes. Its integrated 3D visual grasping and digital twin technology can achieve a 1:1 virtual mapping of the machining process, allowing operators to adjust parameters in real time on the virtual interface. This function has been applied in the small-batch production of aero-engine blades, increasing production efficiency by more than 30%.

1.4 Additive-Subtractive Hybrid Manufacturing: “Efficiency Revolution” through Cross-Border Integration

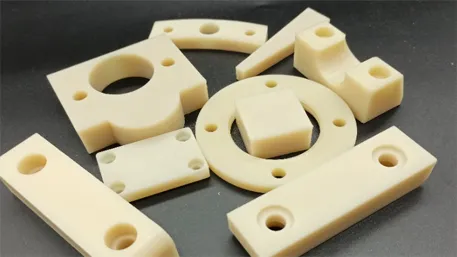

Additive-Subtractive Hybrid Manufacturing (ASHM) combines the “near-net shaping” of 3D printing with the “high-precision finishing” of cutting processing, solving the pain points of low material utilization rate and long processing cycle of traditional processes. Germany’s DMG MORI’s 5-axis additive-subtractive hybrid machining center can achieve integrated production, increasing the material utilization rate of aerospace parts from 30% in traditional processes to 85% and shortening the processing cycle by 40%. This data is from the industrial application case report of Kennametal.

The core breakthrough of relevant foreign technologies is not simply equipment integration, but “optimization of process connection.” For example, to address the residual stress problem of parts after additive manufacturing, DMG MORI’s solution controls the deformation error caused by residual stress within 0.03mm through a “preheating treatment + stepwise cutting” strategy. In addition, patent technologies of American enterprises in the synergistic effect of protective gas and cutting fluid, and the matching of cutting parameters between cladding layers and base materials have been applied in the production of titanium alloy implants for medical devices.

II. Industry Literature and Content Creation: “Authentic Transmission” of Professional Value

Through the analysis of high-impact foreign CNC literature and technical content, the core of their professionalism and readability lies in “authentic data support, precise expression, and implementation orientation,” which provides important reference for industry content creation.

2.1 Topic Selection: Extreme Specialization, Rejecting “Broad and Comprehensive”

Topics of popular foreign literature all focus on specific scenarios, such as “AI Prediction Model for Grinding Wheel Wear in Titanium Alloy Grinding (Based on LSTM Algorithm)” and “Influence of Cladding Layer Hardness on Cutting Force in 5-Axis Additive-Subtractive Hybrid Machining,” closely following the logic of “specific material + specific process + core pain point” to ensure research depth. In contrast, some domestic topics such as “Overview of CNC Technology under the Background of Intelligent Manufacturing” are difficult to form practical value due to lack of focus.

This topic selection logic is highly consistent with the competitive strategy of “technical monopoly in niche segments” adopted by foreign enterprises. For example, FANUC’s in-depth cultivation in AI algorithms for CNC systems and Mitsubishi’s in thermal compensation technology for grinding machines have all formed technical discourse power through literature output.

2.2 Content: Data-Driven, Emphasizing “Verifiability”

The core value of professional CNC content lies in “authenticity and credibility.” Foreign literature presents data extremely rigorously, rejecting vague expressions such as “appropriate adjustment” and “significant improvement.” For example, when verifying a certain error compensation algorithm, it will clearly state that “experiments were repeated 12 times on 3 different models of machine tools and 5 types of materials, with an average error reduction of 37% and a standard deviation ≤0.002mm,” accompanied by 3D surface graphs to show the coupling relationship between parameters.

The writing of technical articles also focuses on “practical orientation.” For example, Mazak’s technical white paper details equipment models, parameter settings, scheduling logic, and even includes investment return analysis such as “initial investment of 3 million yuan, investment recovery in 2 years,” helping enterprises evaluate the feasibility of implementation. This dual presentation of “technical parameters + commercial value” makes the content both professional and practical.

2.3 Cases: Complete Closed Loop, Reflecting “Reflection and Optimization”

The presentation of high-quality foreign cases does not simply list successful experiences, but follows the complete logic of “problem – solution – effect – reflection.” For example, in an auto mold processing case, it clearly puts forward the specific problem of “part deformation caused by excessive grinding temperature (error ≥0.1mm),” provides the solution of “segmented grinding + liquid nitrogen cooling + AI temperature prediction,” shows the actual effect of “deformation error reduced to 0.03mm and efficiency increased by 20%,” and reflects on the improvement direction of “optimizing the energy consumption of the cooling system during mass production.”

This presentation method allows readers not only to reuse the scheme but also to adjust and optimize it according to their own scenarios, reflecting the depth and practicality of the content, which is also an important reason for the high popularity of foreign technical content.

III. Enlightenments for Industry Development: Core Logic of “Technology Implementation”

The evolution of CNC technology is not an isolated technological breakthrough, but a systematic project deeply bound to manufacturing needs and enterprise strategies. From the perspective of global development trends, “authentic implementation,” “data support,” and “in-depth specialization” are the core keywords.

For enterprises, technology selection should avoid blindly pursuing “high-end concepts” and instead focus on actual needs. For example, small and medium-sized manufacturing enterprises do not need to blindly pursue AI-equipped CNC systems; if they mainly produce standardized parts in batches, equipment with basic precision control can meet the needs. In contrast, high-end fields such as aerospace and medical devices need to focus on core indicators such as the precision stability and process adaptability of equipment.

For industry content creators, they should learn from the rigorous style of foreign literature, rely on authentic data and specific cases, and avoid exaggerated expressions and vague theories. Only by focusing on niche pain points in topic selection, emphasizing reproducibility in content, and presenting a complete closed loop in cases can we truly provide valuable references for the industry.

In the future, CNC technology will continue to develop towards the direction of “smarter, more precise, and more flexible.” However, no matter how technology iterates, “creating value through authentic implementation” has always been the core logic of industry development. From the technical accumulation of Japanese and German enterprises to the actual effects of industrial applications, it has been proven that the progress of the CNC industry has never been the “showmanship” of a single technology, but the inevitable result of continuously solving practical problems.