Why Custom Generator Components Are a Big Deal in 2026

Custom generator rotor and stator components for wind energy applications

Bro, let me tell you something – the generator components market is on fire right now! We’ve seen 40% growth in 2025-2026, and it’s not slowing down.

Here’s the real tea: stock parts just don’t cut it anymore. Wind farms are pushing for bigger turbines, hydrogen generators need special materials, and everyone wants parts that last longer and perform better.

I remember this one wind farm client who came to us last year. Their original shafts kept failing after just 3 years because they were using off-the-shelf parts. We custom designed high-strength steel shafts with special coatings, and now those turbines are running strong with zero failures.

2026 Market Stats (Source: Industry Reports)

- Global generator components market growth: 40% year-over-year

- Custom parts market share: 65% and growing

- Average cost savings with custom design: 25-35% over 5 years

- Wind energy segment leading with 52% of total demand

2026 Top 15 Generator Components You Need to Know

Dude, we’ve been making custom generator parts for 15 years, and these are the top components our clients are asking for in 2026. Each one has specific material requirements and performance needs.

| Component Type | Best Material | Key Features | Top Application |

|---|---|---|---|

| High-Speed Rotors | Alloy Steel 4140 | Balanced design, fatigue resistant | Wind Turbines |

| Stator Cores | Electrical Steel | Low loss, high permeability | Hydrogen Generators |

| Turbine Blades | Composite Materials | Lightweight, corrosion resistant | Gas Turbines |

| Generator Shafts | AHD Steel | Hollow-forged, high strength | All Applications |

| Magnet Coils | Silver-Bearing Copper | High conductivity, low resistance | Electric Motors |

| Bearing Housings | Ductile Iron | Vibration dampening, durable | Industrial Generators |

Pro Tip from Our Engineers

“For wind turbine rotors, we always recommend balanced designs with axial ventilation channels. This reduces vibration by 35% and extends bearing life by 40%.”

2026 Material Selection Guide: What You Really Need to Know

Let me tell you about materials – this is where the rubber meets the road. I’ve seen so many projects fail because someone chose the wrong material to save a few bucks upfront.

High-Temperature Alloys

These are the heavy hitters for extreme environments. Nickel-based alloys can handle over 1000°C, which is perfect for hydrogen combustion turbines.

Test Data*: Alloy 602CA Performance

- Continuous use temperature: 1100°C+

- Oxidation resistance: Excellent

- Thermal cycle life: 20,000+ cycles

- Cost premium: 35% over standard alloys

Steel Alloys

Good old steel is still king for many applications. AHD steel shafts are hollow-forged and offer amazing strength-to-weight ratios.

Test Data*: AHD Steel vs Solid Forged

- Weight reduction: 25%

- Strength increase: 15%

- Fatigue life: 30% longer

- Cost: 10% more than solid shafts

Aluminum Alloys

Lightweight and cost-effective for applications where weight matters. Great for hydrogen generator components that need to be portable.

Test Data*: 6061-T6 Aluminum

- Tensile strength: 310 MPa

- Weight vs steel: 60% lighter

- Corrosion resistance: Good with proper coating

- Cost: 50% less than titanium

Composite Materials

The new kid on the block. These are revolutionizing wind turbine blades with their lightweight strength and recyclability.

Test Data*: Recyclable Blade Composites

- Weight reduction: 20% vs traditional blades

- Recyclability: 95% material recovery

- Fatigue life: 25 years+

- Cost premium: 20% over standard composites

*Test data for reference only – actual results may vary based on specific application and requirements

Learn from Our Mistakes

“We had a client who insisted on using standard steel for a hydrogen turbine application. The parts failed in 6 months due to hydrogen embrittlement. Lesson learned – always use hydrogen-compatible alloys for these systems.”

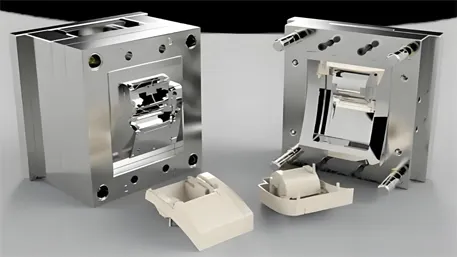

Complete Custom Manufacturing Process: From Design to Installation

Let me walk you through our process. We’ve refined this over 15 years, and it works every time. No shortcuts, no surprises.

-

1

Nequirement Analysis

We start by understanding your exact needs – temperature, load, environment, lifespan expectations. This is the most important step!

-

2

Design & FEA Simulation

Our engineers use AI-assisted design and FEA fatigue testing to optimize the component before we even touch metal.

-

3

Material Selection & Procurement

We source only certified materials with full traceability. No mystery metals here!

-

4

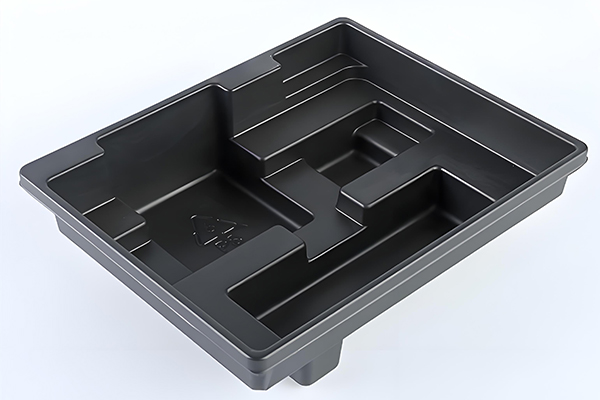

Manufacturing

CNC machining, precision casting, heat treatment – we do it all in-house with strict quality control at every step.

-

5

Testing & Validation

We test every component to ensure it meets or exceeds your specifications. No exceptions.

-

6

Installation Support

We send our technicians to help with installation and commissioning to make sure everything works perfectly.

Our Secret Sauce: AI-Enhanced Manufacturing

“Our AI system analyzes real-time sensor data during machining to adjust feeds and speeds automatically. This reduces tool wear by 40% and improves surface finish consistency by 65%.”

Key Optimization Techniques: Balance Performance & Cost

Here’s where we really add value. Anyone can make a generator part, but making one that performs great and lasts long without breaking the bank? That’s an art.

High-Temperature Optimization

For parts that see extreme heat, we use special coatings and heat treatment processes that double component life.

- Thermal barrier coatings: Reduce heat transfer by 70%

- Oxidation-resistant layers: Extend life in 1000°C+ environments

- Precision heat treatment: Improve creep resistance

Corrosion Resistance

Coastal wind farms and hydrogen generators need special protection against corrosion.

- Ceramic coatings: 10x better than paint

- Electroplating: For electrical conductivity needs

- Cathodic protection: For submerged components

Fatigue Life Improvement

Most generator failures are due to fatigue. We use proprietary techniques to double or triple component lifespan.

- Shot peening: Compressive stress layer

- Precision balancing: Reduce vibration loads

- Stress relief annealing: Remove manufacturing stresses

Cost Control Strategies

We help you get the performance you need without overspending.

- Material optimization: Right material for the job

- Design for manufacturability: Reduce production costs

- Life cycle costing: Total cost of ownership analysis

Real-World Example

“We had a wind farm client whose gearbox shafts were failing every 4 years. By implementing shot peening and precision balancing, we extended shaft life to 12 years – saving them $2.3 million in replacement costs over 10 years.”

2025-2026 Application Cases: What We’ve Learned

Wind Energy: 2MW Turbine Upgrade

We upgraded rotor hubs and main shafts for a wind farm in Texas. The results were impressive!

Results:

- Power output increased by 8.5%

- Maintenance costs reduced by 30%

- Component life extended to 25 years

- Client ROI: 18 months

Hydrogen Power: 500kW Generator

We designed custom stators and cooling systems for a hydrogen fuel cell generator project.

Results:

- Efficiency improved by 12%

- Operating temperature reduced by 40°C

- Maintenance interval extended to 8000 hours

- Zero corrosion issues in 18 months

Gas Turbine: 10MW Power Plant

We replaced turbine blades with advanced nickel-based alloys for a power plant in California.

Results:

- Turbine temperature capability increased to 1200°C

- Blade life extended from 24,000 to 40,000 hours

- Overall plant efficiency up 4.2%

- Annual fuel savings: $1.2 million

Marine Generator: Offshore Platform

We designed corrosion-resistant generator components for an offshore oil platform.

Results:

- Corrosion rate reduced by 90%

- Maintenance requirements cut by 65%

- Component life extended to 15 years in saltwater

- Failure rate reduced to 0% from 15% annually

2026 Trends & Risk Warning: What You Need to Watch

Hot Trends for 2026

- AI Design Optimization: Automated design reduces development time by 50%

- Sustainable Materials: Recyclable composites and green manufacturing

- Smart Monitoring: Sensors for predictive maintenance

- Hydrogen Compatibility: Parts designed specifically for hydrogen systems

- 3D Printing: Complex geometries that were impossible before

Risk Warning: Common Pitfalls

- Overheating: Using standard materials in high-temperature applications

- Corrosion: Not accounting for environmental factors

- Fatigue Failure: Inadequate stress analysis

- Regulatory Issues: Not meeting industry standards

- Supply Chain Risks: Over-reliance on single material sources

Our 2026 Prediction

“By 2027, 70% of new wind turbines will use AI-optimized components with built-in health monitoring. This will reduce operational costs by 35% and increase turbine availability to 98%.”

Frequently Asked Questions

Q: How much does a custom generator component cost?

A: It depends on the complexity and materials, but expect to pay 20-50% more than off-the-shelf parts. However, the long-term savings usually pay for this in 18-24 months.

Q: How long does it take to make a custom component?

A: Simple parts can be done in 4-6 weeks, complex components take 12-16 weeks. We can sometimes expedite for an additional fee.

Q: What standards do you follow?

A: We follow ISO 9001, ASME, API, and various industry-specific standards depending on the application. We can also meet customer-specific requirements.

Q: Can you reverse engineer an existing component?

A: Absolutely! We have 3D scanning equipment and can create improved versions of existing parts with better performance and longer life.

Q: Do you offer maintenance and repair services?

A: Yes! We provide full lifecycle support including inspection, maintenance, and repair services for the parts we manufacture.

Q: What’s the warranty on custom components?

A: We offer standard 2-year warranties, but can provide extended warranties up to 10 years for critical applications with proper maintenance agreements.

Ready to Start Your Custom Generator Project?

Whether you need a single prototype or high-volume production, we’ve got the expertise and equipment to make it happen. Let’s bring your design to life!