Core Question: How Can Small & Medium-Sized Factories Adopt Smart Machining at Low Cost? Key Tech & Practical Results

Adaptive Machining Systems: Control Precision in Real Time, Cut Scrap Rate by 30%

In traditional machining, fluctuations in material hardness and tool wear often cause over-cutting or under-cutting. One precision parts manufacturer once faced an 18% scrap rate, with equipment managers spending 2.5 hours daily manually adjusting tool offsets. Adaptive machining systems solve this root problem through real-time data collection and dynamic adjustments.

-

Technical Principles & Core Value

- The system collects 12 real-time data points (via edge gateways) including cutting force (accuracy ±0.1N), spindle vibration (0-5000Hz), and cutting temperature (-20℃-800℃, accuracy ±0.5℃), with a response latency ≤100ms. If excessive material hardness pushes cutting force beyond the threshold, it automatically reduces feed rate by 5%-30%; if abnormal vibration from tool wear occurs, it fine-tunes cutting depth to avoid over-cutting.

- Key Benefits: Scrap rate drops by 25%-35%, tool offset adjustment time is cut by over 80%, and Overall Equipment Efficiency (OEE) rises by 20%-28%.

-

Key Implementation Tips

- Equipment Compatibility: Prioritize solutions supporting 20+ mainstream CNC systems. Older machines (e.g., Fanuc 0i series post-2010) can be retrofitted without hardware replacement, slashing single-machine modification costs by 30%.

- Parameter Setting: Preset thresholds based on machining type—set vibration warning to 20μm for aluminum milling, and temperature threshold to 500℃ for stainless steel cutting—to avoid false or missed alerts.

- Case Reference: After deployment at an auto parts factory in Suzhou, 20 machines ran 2.4 extra hours daily, monthly output increased by 12%, and defective products decreased by 320 units monthly.

Smart Tool Monitoring: Predict Wear in Advance, Boost Life Utilization by 25%

Sudden tool failure is a top cause of machining interruptions. Traditional “experience-based” tool replacement wastes over 15% of tool life. AI-driven tool monitoring systems accurately predict lifespan, avoiding batch scrapping risks.

-

Mainstream Monitoring Solutions & Selection

- Vibration Sensor Solution: Ideal for milling. It judges wear by monitoring vibration frequency changes, installed on spindles or turrets, with accuracy up to ±0.1μm, costing ~3,000-8,000 RMB per unit.

- Acoustic Emission Sensor Solution: Suits drilling and turning. It captures sound signals from tool-material friction, detecting early micro-cracks—perfect for hard-to-machine materials like titanium alloy.

- Image Recognition Solution: Uses CCD cameras to capture tool images, with deep learning algorithms calculating wear volume. Combined with laser measurement, it enables precise wear quantification (error ≤0.001mm).

-

Practical Implementation Strategies

- Collect 30 minutes of baseline data when a new tool is first used, building a full-cycle model (“running-in → stable → failure”). Set the warning threshold to 20% of remaining life before failure.

- Link with the tool offset system: When wear reaches 0.1mm, automatically trigger offset adjustments (no manual input needed). A mold factory saw tool life utilization rise from 60% to 85% after application, saving 12,000 RMB monthly on tools.

Digital Twins: Virtual Rehearsal Prevents Errors, Cuts Commissioning Time by Half

Invisible internal machine states and program errors often cause collisions—an aerospace enterprise once faced frequent machining accidents. Digital twins create a 1:1 virtual machine, enabling visual management of the entire machining process.

-

Core Application Scenarios

- Tool Path Simulation & Verification: Simulate complex curved surface machining in a virtual environment to detect over-cutting or interference in advance. One enterprise reduced trial-cut scrap rate from 12% to 0.5% this way.

- Predictive Maintenance: Monitor spindle load and guideway temperature in real time; issue alerts when load fluctuations exceed 15%, cutting unplanned downtime by 40%.

- Process Optimization: Adjust cutting parameters virtually to find the optimal “speed-feed-depth” combination. A mold factory boosted machining efficiency by 30%.

-

Low-Cost Implementation Path

- Small/medium factories can start with single-machine digital twin software (compatible with mainstream CNC systems) for as low as 5,000 RMB annually, focusing on program verification.

- Prioritize connecting key components (spindle, feed axis) for data collection—no full sensor deployment needed. Initial investment can be kept under 20,000 RMB.

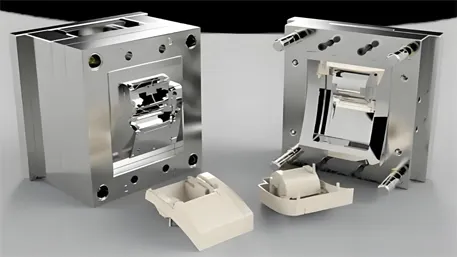

Flexible Automation: Efficient Small-Batch Production, 10-Minute Changeovers

With more multi-batch, small-lot orders, traditional manual loading/unloading is inefficient and error-prone. Flexible automation systems use modular design to enable fast changeovers and unmanned production.

- Mainstream Solutions & Applicable Scenarios

| Solution Type | Core Configuration | Applicable Scenarios | Efficiency Improvement |

|---|---|---|---|

| Single-Machine Robot | 6-axis collaborative robot + 3D vision | Small-batch precision parts (<50 units) | Loading/unloading efficiency +120% |

| AGV-Robot System | AMR + collaborative arm + auto charger | Multi-machine linked production | Night-shift output +200% |

| Modular Production Line | Robot + quick-change fixtures | Multi-variety changeovers (e.g., injection/stamping molds) | Changeover time <10 minutes |

- Pitfall Avoidance & Efficiency Tips

- Choose collaborative robots with ±0.03mm repeat positioning accuracy—balancing precision and safety, no extra guardrails needed.

- For small-batch orders, use “combined-order production + flexible fixtures”. An auto mold factory raised equipment utilization from 72% to 88% with this method.

Smart Transformation Guide: Low-Cost Startup for Small & Medium Factories

-

Phased Implementation Strategy

- Phase 1 (1-3 months): Deploy tool monitoring + online measurement modules first (investment 30,000-50,000 RMB) to quickly reduce scrap rates.

- Phase 2 (6-12 months): Add adaptive machining systems; with government technical transformation subsidies, actual investment can drop by another 30%.

- Phase 3 (1-2 years): Introduce digital twins and flexible automation for full-process smart management.

-

Key Pitfalls to Avoid

- Don’t blindly pursue “full smartness”: Retrofit data interfaces for older machines first (instead of replacing them), cutting single-machine costs by 60%.

- Unify data integration: Use universal protocols like NC-Link to ensure data flow between sensors, machines, and cloud platforms—avoid information silos.

- Prioritize staff training: Let operators master basic skills (threshold adjustment, alert handling) via manufacturer-provided hands-on training; otherwise, systems risk becoming “decorations”.

Summary: The “Success Formula” for Smart Machining

Clear needs (right tech modules) + compatible solutions (fit existing equipment) + data-driven decisions (real-time parameter optimization) + phased implementation (control initial costs) = scrap rate -25%+, efficiency +30%+, tool costs -15%+. Small/medium factories don’t need to “do it all at once”—start with solving core pain points (e.g., high scrap rates, heavy tool wear) to launch smart transformation at low cost and see quick results.