In today’s industrial landscape, CNC machining stands as a cornerstone technology, powering sectors from construction and electronics to medical device manufacturing. Among the materials used in this process, aluminum reigns supreme—valued for its lightweight nature, flexibility, and exceptional machinability. Whether you’re crafting complex aerospace components or everyday electronic parts, aluminum machining delivers efficient, precise solutions that meet even the most rigorous technical requirements.

In this comprehensive guide, we’ll break down the fundamentals of aluminum machining, explore its key advantages, highlight the best aluminum alloys for the job, detail essential machining techniques, and showcase its wide-ranging applications.

What Is Aluminum CNC Machining?

Aluminum machining is a specialized technical process that uses machine tools to cut, shape, and form aluminum into parts of varying sizes and complexities. Aluminum’s unique properties make it an ideal choice for countless industrial applications: it is highly versatile, naturally corrosion-resistant, and capable of producing products with an excellent surface finish—critical for high-precision sectors.

Unlike heavier, costlier metals such as iron or steel, aluminum offers a rare balance of benefits:

- Superior machinability: It can be shaped more easily than most metals, reducing production time and costs.

- Strength-to-weight ratio: It delivers impressive strength without adding excess weight, making it perfect for weight-sensitive applications (e.g., automotive or aerospace).

- Durability: Its corrosion resistance ensures parts hold up in harsh environments, from marine settings to chemical plants, with minimal maintenance.

CNC (Computer Numerical Control) aluminum machining takes this process a step further, using computer programs to control machine tools. This automation eliminates human error, ensuring consistent precision and repeatability—even for the most intricate part designs.

The Core Advantages of Aluminum CNC Machining

Aluminum’s inherent characteristics make it a top choice for CNC machining and industrial machinery design. Below are the key benefits that set it apart from other materials:

1. Exceptional Machinability & Malleability

Aluminum is far more malleable and machinable than metals like copper, iron, and steel. This means it can be cut, drilled, and shaped quickly—even into complex geometries—without compromising structural integrity. For high-tech sectors like automotive manufacturing, this translates to faster production of parts such as engine components, transmission housings, and suspension parts.

CNC machining techniques maximize this advantage: processes like milling, turning, and drilling achieve extreme precision with aluminum, ensuring parts meet tight tolerances (often as small as ±0.001 inches). This makes aluminum ideal for custom or high-volume production runs.

2. Corrosion Resistance & Lightweight Design

Aluminum’s natural oxide layer acts as a barrier against rust and corrosion, making it suitable for outdoor, marine, or chemical-exposed applications. For example, marine industries rely on aluminum parts for boat hulls and fittings, while chemical plants use it for storage tanks and piping.

To enhance this durability further, manufacturers often apply surface treatments like anodizing, powder coating, or chromate conversion—all of which boost corrosion resistance without adding significant weight. Speaking of weight: aluminum is approximately 1/3 the weight of steel, making it a go-to for applications where weight reduction is critical (e.g., aircraft fuselages or electric vehicle frames).

3. Excellent Thermal & Electrical Conductivity

Aluminum ranks among the best conductors of heat and electricity, second only to copper in many cases. This property makes it indispensable for:

- Heat exchangers: Used in HVAC systems, car radiators, and industrial cooling units to dissipate heat efficiently.

- Electronic components: From computer CPU 散热器 (heat sinks) to power transmission lines, aluminum ensures electronics stay cool and function reliably.

In industries where overheating can damage equipment (e.g., medical devices or aerospace electronics), aluminum’s thermal conductivity is not just a benefit—it’s a necessity.

The Best Aluminum Alloys for Machining

Not all aluminum alloys are created equal. The right alloy depends on your project’s requirements (e.g., strength, corrosion resistance, or formability). Below are the most common categories and top choices for machining:

1. Wrought & Heat-Treatable Alloys

Wrought alloys are shaped by processes like rolling, extrusion, or forging, and many can be heat-treated to enhance mechanical properties (e.g., hardness, fatigue resistance). The most widely used series for machining include:

| Alloy Series | Key Alloying Element | Key Properties | Ideal Applications |

|---|---|---|---|

| 2xxx Series | Copper | High tensile strength, good fatigue resistance | Aerospace components (e.g., aircraft wings, landing gear) |

| 6xxx Series | Magnesium + Silicon | Balanced strength, weldability, and corrosion resistance | Structural parts (e.g., automotive frames, construction beams, machinery components) |

| 7xxx Series | Zinc | Highest strength of all aluminum alloys | High-stress applications (e.g., aerospace structural parts, sports equipment) |

The Most Popular Wrought Alloys for Machining

- 7075 Aluminum: Renowned for its ultra-high tensile strength (comparable to some steels) and lightweight. It’s a staple in aerospace (e.g., fighter jet components) and sports equipment (e.g., bicycle frames, climbing axes).

- 6061 Aluminum: The “workhorse” of aluminum alloys—versatile, weldable, and corrosion-resistant. It’s used in everything from bridge structures and building facades to motorcycle parts and camera tripods.

- 3003 Aluminum: Highly malleable and corrosion-resistant, with good formability. Common uses include fuel tanks, ventilation ducts, and kitchen appliances (e.g., aluminum foil containers).

- 5083 Aluminum: Offers the best corrosion resistance among non-heat-treatable alloys, making it perfect for marine applications (e.g., boat hulls, offshore platforms) and chemical processing equipment.

2. Aluminum Die Casting Alloys

Die casting alloys are melted and injected into molds under high pressure, making them ideal for producing complex, intricate parts in large quantities. Their key advantages include excellent fluidity (for filling detailed molds) and heat resistance.

Common uses for die-cast aluminum alloys include:

- Motor housings (for appliances, power tools, and electric vehicles)

- Electronic enclosures (e.g., smartphone chargers, sensor casings)

- Automotive components (e.g., steering knuckles, pump bodies)

These alloys eliminate the need for complex post-machining in many cases, reducing production time and costs for high-volume projects.

Key Aluminum Machining Techniques (Including CNC)

Aluminum can be processed using a range of techniques, each tailored to specific part shapes and requirements. Below are the most essential methods:

1. Milling

Milling uses rotating cutting tools (mills) to remove material from aluminum workpieces. It’s ideal for creating parts with complex shapes, slots, holes, or multiple surfaces—such as mechanical brackets, engine blocks, and aerospace components.

CNC milling takes this further by using computer controls to adjust tool speed, feed rate, and depth, ensuring consistent precision across every part. This technique is especially useful for custom designs or parts that require tight tolerances.

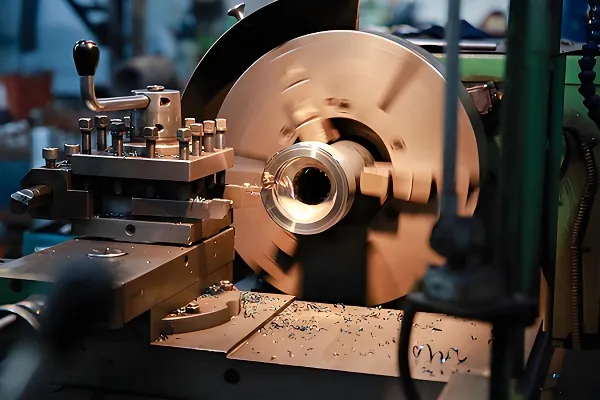

2. Turning

Turning involves rotating the aluminum workpiece on a central axis while a stationary cutting tool shapes it. This process is perfect for creating cylindrical or symmetrical parts, such as:

- Shafts (for motors or gearboxes)

- Bearings

- Bolts and fasteners

CNC turning machines can produce these parts quickly and accurately, even for high-volume orders.

3. Drilling

Drilling is a straightforward but critical technique: it creates precise holes in aluminum for fasteners (e.g., screws, bolts) or to integrate other components. CNC drilling ensures holes are perfectly aligned and sized, avoiding issues like misalignment that can compromise part performance.

4. CNC Aluminum Machining: The Gold Standard

As mentioned earlier, CNC machining revolutionizes aluminum processing. Its key benefits for aluminum include:

- Precision: Computer controls eliminate human error, achieving tolerances as tight as ±0.0005 inches.

- Repeatability: Every part is identical, critical for batch production.

- Flexibility: Easily switch between designs by updating the CNC program—no need to retool extensively.

- Speed: Automated processes reduce cycle times, cutting lead times for projects.

Whether you’re producing 10 custom parts or 10,000 identical components, CNC aluminum machining delivers efficiency and quality.

Where Is Aluminum Machining Used?

Aluminum’s versatility makes it a favorite across nearly every major industry. Below are its most common applications:

1. Aerospace & Automotive Industries

- Aerospace: Aluminum is used for fuselage structures, wing components, engine parts, and landing gear—thanks to its strength-to-weight ratio and corrosion resistance. Alloys like 7075 and 6061 are industry staples.

- Automotive: From electric vehicle (EV) frames (reducing weight to extend range) to engine blocks and heat exchangers, aluminum helps improve fuel efficiency and performance.

2. Medical Devices & Sports Equipment

- Medical: Aluminum is used for wheelchair frames, surgical instrument handles, and diagnostic equipment housings—its lightweight design eases mobility, and its corrosion resistance ensures sterility.

- Sports: Bicycle frames, golf clubs, ski poles, and camping gear all rely on aluminum for durability and lightness.

3. Construction & Electronics

- Construction: Aluminum is used for window frames, curtain walls, roofing, and structural beams—its corrosion resistance stands up to weather, and its light weight simplifies installation.

- Electronics: Heat sinks for CPUs, laptop casings, and power supply enclosures use aluminum’s thermal conductivity to keep devices cool.

Conclusion

Aluminum machining—especially CNC aluminum machining—remains a cornerstone of modern industry, thanks to aluminum’s unique blend of strength, lightness, and machinability. From aerospace to electronics, it powers the parts that keep our world running.

By understanding the basics of aluminum machining, choosing the right alloy, and partnering with a trusted expert like XIAMEN GOLDCATTLE, you can ensure your project is completed on time, on budget, and to the highest quality standards. For more insights into metal processing, explore our guides on cast iron machining, plastic machining, and stainless steel machining.