When it comes to industrial materials, aluminum is the ultimate workhorse. It’s strong yet lightweight, resists corrosion, and machines like a dream—no wonder you’ll find it everywhere from automotive parts to aerospace components and electronics. Here at Xiamen Goldcattle, we’ve been specializing in high-precision aluminum machining for over a decade, serving clients across the U.S. and Europe. Whether you need a single prototype or large-scale production, we deliver fast turnaround times without compromising on quality.

Why Aluminum is Perfect for CNC Machining

Any manufacturer worth their salt knows material selection makes all the difference. Aluminum alloys are total all-stars for CNC machining:

- Lightweight but strong enough to handle heavy-duty applications

- Naturally corrosion-resistant, so it holds up in outdoor or humid environments

- Excellent thermal and electrical conductivity—ideal for heat sinks and electronics

- Machines smoothly with minimal effort, producing super clean surfaces and tight tolerances

Whether you’re testing a prototype, building structural components, or creating high-performance assemblies, aluminum gets the job done right.

What We Can Do for Your Aluminum Machining Needs

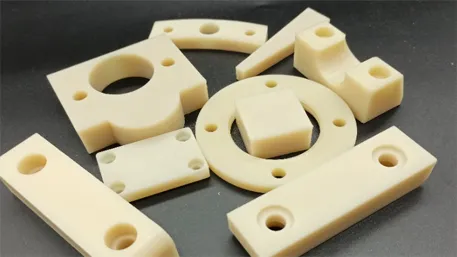

We handle every step from design to finished product, covering all your aluminum machining requirements:

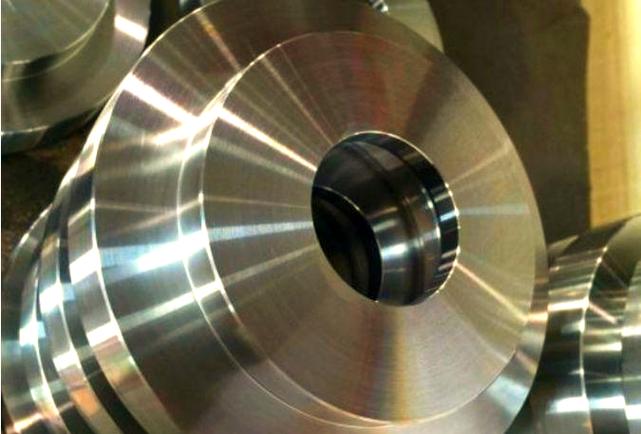

Basic CNC milling and turning are just the start—for complex parts, our 5-axis machining centers are game-changers. The beauty of 5-axis tech? It machines multiple surfaces in one setup, cutting down on repositioning errors. Those tricky parts with angled holes or curved surfaces that used to require multiple machines? Now we can produce them in a single run, which means better precision across the board. We’re talking tolerances as tight as ±0.01mm—about the thickness of a human hair.

Our shop’s packed with serious equipment: Japanese Fanuc and German Siemens CNC systems paired with high-speed machining centers running at 15,000 RPM. We can mill aluminum at feed rates up to 10 meters per minute, which means faster production without sacrificing finish—we’re talking mirror-smooth surfaces when needed. We’ve got specialized carbide-coated tools for different alloys too; for tough stuff like 7075, we use ultra-fine grain tools that reduce cutting force and prevent warping.

Order quantities don’t faze us—we’ll take on a single prototype or scale up to mass production. Need samples in a hurry? We can turn around simple parts in as little as 24 hours, with most prototypes ready within a week.

We handle all finishes in-house too: anodizing up to 12-25 microns thick that passes 480-hour salt spray tests after sealing; powder coating using AkzoNobel powders that achieve 0-class adhesion—scratch-resistant enough for heavy use. No matter how complex your part geometry or how tight your tolerances, our equipment and team have you covered.

All the Aluminum Alloys You Could Need

Different industries demand different materials, so we stock all the industrial-grade aluminum alloys you might require:

6061 is our workhorse—versatile and cost-effective for most structural components

7075 brings the strength for aerospace and automotive applications where durability matters most

2024 offers excellent fatigue resistance, perfect for parts under repeated stress

5052 combines corrosion resistance with weldability, ideal for outdoor equipment and marine parts

We also carry 6082, 5083, and more—just ask if you need something specific.

We’re Fanatical About Quality Control

When it comes to industrial parts, quality isn’t optional—that’s why we obsess over every detail from start to finish:

We’re ISO 9001:2015 certified, so every step follows international standards

Our workshop stays temperature-controlled at 20±1℃ to prevent thermal expansion from affecting precision

Finishes like anodizing meet RoHS requirements—no worries about environmental compliance

Need CE certification for your industry? We’ll provide all the documentation you need

Every batch gets inspected with our Coordinate Measuring Machine (CMM) that hits 0.001mm accuracy, and we use in-process monitoring to check dimensions during machining—if something’s off, we adjust immediately. You’re not just getting parts—you’re getting guaranteed quality and consistency.

Industries We Know Inside Out

We’ve worked with enough sectors over the years to understand exactly what each one needs:

Automotive precision components, aerospace high-strength parts, electronics heat sinks, medical device components, industrial automation Transmission parts,consumer product structures—the list goes on.

Whether you’re testing a single sample or ramping up to full production, we’ll tailor our services to match your project’s unique requirements.

Real-World Projects That Speak for Themselves

Talk is cheap—here’s what we’ve actually delivered:

Automotive Transmission Components

A European auto parts manufacturer needed 6061 aluminum shift components with ±0.02mm tolerances and wear-resistant anodizing. Their previous supplier kept having issues with chamfers and hole diameters causing assembly jams. We produced them on our 5-axis machines with real-time in-process inspection, delivered samples in 3 days, and now maintain 99.8% pass rates in mass production—we’ve been supplying them steadily for over two years.

Aerospace Drone Brackets

A U.S. client needed 7075 aluminum load-bearing brackets for their drone project—lightweight but impact-resistant, with salt spray certification. We redesigned their original welded structure to a one-piece machined part, eliminating stress points. Using specialized tools solved their 7075 sticking issues, and our hard anodizing treatment let the parts pass 480-hour salt spray tests. The final components were 15% lighter than their original design, meeting full aerospace standards.

Electronics Cooling Modules

A domestic server manufacturer needed 5052 aluminum heat sinks with hundreds of 0.8mm micro-cooling holes and surface roughness under Ra1.6μm. Our high-speed milling with precision cooling prevented thermal distortion, keeping hole positioning within ±0.01mm. Post-finishing, their testing showed 20% better heat dissipation than their previous design—we now supply 5,000 units monthly.

Why Clients Choose Xiamen Goldcattle

After a decade in the business, we’ve built our reputation on reliability and expertise:

- 26 years means we’ve seen every complex part and tricky requirement—we know aluminum machining inside out

- We’ll review your designs first, offering DFM (Design for Manufacturability) advice to optimize your parts before production

- We’ve got dedicated teams for U.S. and European clients, handling time zone coordination and standard compliance seamlessly

- We treat single prototypes with the same care as mass orders—no minimum quantity headaches

- Fast responses and quick lead times—our clients consistently praise how easy we are to reach and work with

Need a Quote? We’ve Got You Covered

Got a custom aluminum component in mind? Send us your 3D drawings or technical specs anytime. Our engineers will get you a detailed quote within 24 hours, and we’ll even flag design optimizations if we see them. Got questions? Just ask—we’re here to make your project a success.