- Picture type (single photo, multiple photos, or 2D illustrations);

- Precision needs (concept prototype vs. industrial-grade accuracy);

- Tool familiarity (AI tools for beginners, professional software for experts).

- AI-Powered Single-Image Conversion (fast, no skills needed—best for quick prototypes);

- Photogrammetry (Multiple Images) (higher accuracy—best for real objects like products or artifacts);

- Manual 2D-to-3D Modeling (industrial precision—best for engineering parts or detailed designs).

1. Preparatory Work: What You Need Before Starting

A. Picture Requirements (Critical for Success)

|

Method

|

Image Type

|

Image Quality Rules

|

|

AI Single-Image

|

Single photo/illustration

|

– High resolution (≥1920x1080px); – Even lighting (no harsh shadows/overexposure); – Clear edges (avoid blurry details).

|

|

Photogrammetry

|

15–30 photos of 1 object

|

– 360° coverage (shoot object from top, bottom, sides); – 60%+ overlap between photos (so software can match features); – No moving objects / 反光 (e.g., avoid glass or metal glare).

|

|

Manual 2D-to-3D

|

2D blueprint/illustration

|

– High contrast (black lines on white background); – Multiple views (front/side/top if possible); – Labeled dimensions (for precision).

|

B. Tool Selection (Free vs. Professional)

|

Skill Level

|

Method

|

Free Tools

|

Professional Tools

|

|

Beginner

|

AI Single-Image

|

Luma AI (mobile), Meshy (web), Adobe Firefly (web)

|

MidJourney (with 3D export), Daz3D Bridge

|

|

Intermediate

|

Photogrammetry

|

COLMAP (desktop), Polycam (mobile), Meshroom

|

Agisoft Metashape, RealityCapture

|

|

Expert

|

Manual 2D-to-3D

|

Blender (desktop), SketchUp Free

|

SolidWorks, Rhino, Autodesk Fusion 360

|

2. Method 1: AI-Powered Single-Image Conversion (For Beginners)

Step-by-Step with Luma AI (Free Mobile Tool):

- Download & Set Up: Install Luma AI (iOS/Android) and create a free account.

- Upload Your Image: Tap “Create” → “From Photo” → Select your high-res image (e.g., a photo of a coffee mug).

- Customize Model Settings:

-

- Choose “Model Type”: “Object” (for physical items) or “Scene” (for environments like rooms).

-

- Adjust “Detail Level”: “Low” (fast, small file) or “High” (more polygons, better for close-ups).

- Generate the 3D Model: Tap “Generate” → Wait 5–10 minutes (AI processes depth and geometry).

- Optimize & Export:

-

- Use the app’s “Simplify” tool to reduce polygon count (for 3D printing, aim for 10k–50k polygons).

-

- Export as .GLB (for rendering) or .STL (for 3D printing).

Pros & Cons:

- Pros: Fast (5–30 minutes), no skills needed, free tier available.

- Cons: Low precision (AI guesses depth—may have distorted areas), not suitable for industrial parts.

Best For:

- Concept art (e.g., turning a character sketch into a 3D model for game development).

- Quick 3D printing prototypes (e.g., a simple toy or decorative item).

3. Method 2: Photogrammetry (Multiple Images for Higher Accuracy)

Step-by-Step with Polycam (Free Mobile Tool):

- Prepare the Object:

-

- Place the object on a plain background (white/black) to avoid background noise.

-

- Use soft lighting (e.g., two lamps) to eliminate harsh shadows (shadows confuse the software).

-

- For small objects (e.g., a key), use a tripod to keep camera stable.

- Take 15–30 Overlapping Photos:

-

- Start at eye level with the object → Take a photo.

-

- Move 10–15° around the object → Take another photo (ensure 60% of the previous photo’s content overlaps).

-

- Cover all angles: Top, bottom, front, back, and sides (e.g., 5 photos around the middle, 5 from the top, 5 from the bottom).

- Import to Polycam:

-

- Open Polycam → Tap “Photogrammetry” → Select all photos.

- Reconstruct the Model:

-

- Tap “Process” → Choose “Accuracy”: “Medium” (10–15 minutes) or “High” (20–30 minutes).

-

- The software will:

- Clean Up & Export:

-

- Use the “Erase” tool to remove background mesh (e.g., the table the object was on).

-

- Use “Smooth” to fix rough areas (e.g., uneven surfaces on a scanned cup).

-

- Export as .STL (3D printing) or .OBJ (editing in Blender).

Pro Tips for Better Results:

- Avoid reflective objects (e.g., metal cups): Cover them with matte tape to reduce glare.

- For large objects (e.g., a chair), use a DSLR camera (higher resolution than a phone).

- Use COLMAP (free desktop tool) for industrial-grade precision (but requires a powerful computer).

Best For:

- Product design (scanning a physical prototype to edit in CAD software).

- 3D printing replicas (e.g., scanning a broken part to print a replacement).

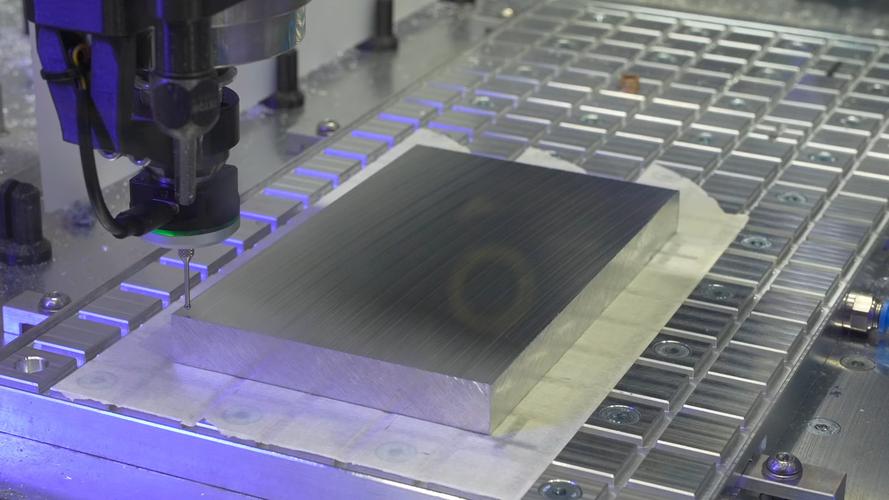

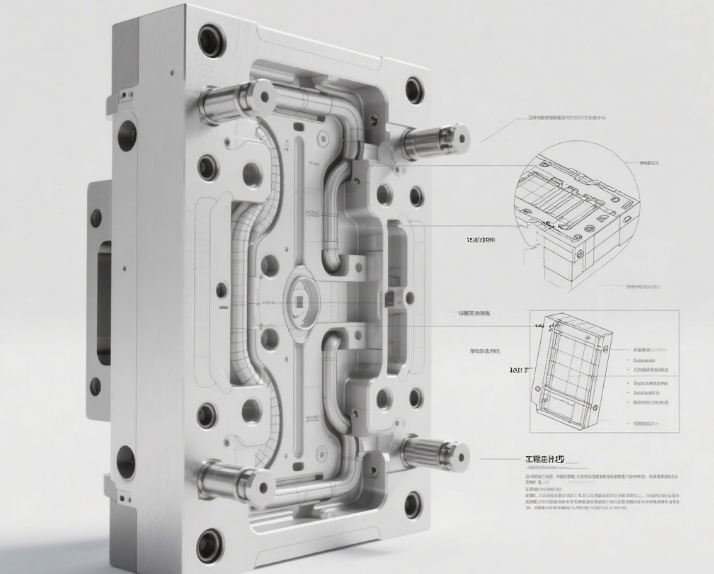

4. Method 3: Manual 2D-to-3D Modeling (Industrial Precision)

Step-by-Step with Blender (Free Desktop Tool):

- Import the 2D Image as a Reference:

-

- Open Blender → Delete the default cube → Go to “Add” → “Image” → “Reference.”

-

- Select your 2D image (e.g., a blueprint of a gear) → Align it to the “Front” view (press “1” on the numpad).

-

- Add a second reference image (if available) for the “Side” view (press “3” on the numpad) to ensure depth accuracy.

- Trace the 2D Outline:

-

- Go to “Edit Mode” → Select the “Line” tool → Trace the outer edges of the image (e.g., the circle of the gear).

-

- Use the “Snap” tool (enable in the top bar) to align lines to the image’s edges (avoids uneven curves).

-

- Close the outline (ensure the last point connects to the first) to create a “closed loop” (required for extrusion).

- Extrude the 2D Outline into 3D:

-

- Go to “Object Mode” → Select the traced outline → Press “E” (extrude) → Drag the mouse to set the depth (e.g., 5mm for a thin gear).

-

- Type the exact depth (e.g., “5mm”) in the bottom bar for precision (critical for engineering parts).

- Add Details:

-

- For holes (e.g., the center of the gear), trace a smaller circle in the middle of the outline → Extrude it through the gear (press “E” then “Enter” to extrude through).

-

- Use the “Loop Cut” tool to add edges for strength (e.g., adding a loop cut around the gear’s teeth).

- Validate & Export:

-

- Use the “Measure” tool to check dimensions (e.g., ensure the gear’s diameter is 50mm as per the blueprint).

-

- Fix “non-manifold geometry” (common error: overlapping edges) using Blender’s “Clean Up” tool → “Delete Loose Geometry.”

-

- Export as .STEP (for CAD software like SolidWorks) or .STL (3D printing).

Best For:

- Industrial parts (e.g., gears, brackets, or machine components from blueprints).

- Architectural designs (e.g., turning a 2D floor plan into a 3D model of a room).

- High-precision 3D printing (e.g., replacement parts for machinery).

5. Scene 化选择指南: Which Method Should You Use?

|

Your Goal

|

Best Method

|

Tool Recommendation

|

Expected Precision

|

|

Quick prototype of a sketch/photo

|

AI Single-Image

|

Luma AI (mobile)

|

±5–10mm

|

|

Scan a physical object (e.g., a mug)

|

Photogrammetry

|

Polycam (mobile) or COLMAP (desktop)

|

±1–3mm

|

|

Engineering part from a blueprint

|

Manual 2D-to-3D

|

Blender (free) or SolidWorks (pro)

|

±0.1–0.5mm

|

|

3D print a replacement part (e.g., a hinge)

|

Photogrammetry (scan the old part)

|

Polycam

|

±1mm

|

|

Game asset from a character illustration

|

AI Single-Image + Blender edit

|

Meshy (AI) + Blender (optimize)

|

Visual accuracy (no exact dimensions)

|

6. Common Mistakes & How to Fix Them

Mistake 1: Blurry/Overexposed Photos

- Problem: AI/photogrammetry software can’t detect edges, leading to a distorted model.

- Fix: Retake photos in natural light (avoid direct sunlight) with a high-resolution camera (≥12MP). Use the camera’s “grid” mode to ensure straight shots.

Mistake 2: Not Overlapping Photos Enough (Photogrammetry)

- Problem: Software can’t match features between photos, leading to missing parts of the model.

- Fix: Ensure 60%+ overlap—if you’re unsure, take more photos (30 vs. 15) to cover gaps.

Mistake 3: Single-Image AI for Industrial Parts

- Problem: AI guesses depth, so the model won’t match exact dimensions (e.g., a 10mm thick part becomes 8mm).

- Fix: Use photogrammetry (scan the physical part) or manual modeling (trace the blueprint) for precision.

Mistake 4: Ignoring Model Clean-Up

- Problem: The model has “non-manifold geometry” (gaps/overlaps) that causes 3D printing failures.

- Fix: Use Blender’s “Clean Up” tool or Meshlab (free) to:

7. Post-Processing: Make Your Model Ready for Use

- Simplify Polygon Count:

-

- For 3D printing: Use Meshlab’s “Quadric Edge Collapse Decimation” tool to reduce polygons to 10k–50k (too many polygons slow slicing).

-

- For rendering: Keep 100k–500k polygons (more details for close-ups).

- Fix Topology:

-

- Ensure the model is “watertight” (no gaps): Use Blender’s “Select Non-Manifold” tool to find gaps → Fill them with the “Fill” tool.

- Assign Materials:

-

- For rendering: Add textures (e.g., wood grain for a table) using Blender’s “Material Properties” tab.

-

- For 3D printing: No materials needed—just export as .STL (slicers like Cura handle material settings).

8. Practical Example: Turning a Coffee Mug Photo into a 3D Print

- Method: Photogrammetry (Polycam).

- Steps:

-

- Take 20 photos of the mug (5 around the middle, 5 top, 5 bottom, 5 sides).

-

- Import to Polycam → Process in “Medium” accuracy.

-

- Erase the table background → Smooth the mug’s handle (rough from scanning).

-

- Export as .STL → Open in Cura (slicer) → Set 0.2mm layer height.

-

- 3D print with PLA filament.

- Result: A functional 3D print of the mug (±1mm precision) that fits the original mug’s lid.

Conclusion: Start Simple, Then Upgrade

- Begin with AI tools (Luma AI/Meshy) to learn how 2D images translate to 3D.

- Once you’re comfortable, try photogrammetry (Polycam) for scanning physical objects.

- For industrial needs, learn Blender/SolidWorks for manual 2D-to-3D modeling.