A CNC (Computer Numerical Control) system is the “brain” that automates machine tools, translating digital instructions into precise physical movements. It operates through a coordinated sequence of steps involving hardware and software, ensuring accurate, repeatable manufacturing.

What are the core components of a CNC system?

A CNC system consists of four key elements working together:

- CNC controller: The central computer that processes instructions and manages machine operations.

- Input devices: Tools to load programs (e.g., USB drives, network connections, or manual data input panels).

- Machine tool: The physical equipment (e.g., mill, lathe, router) that shapes materials, with motors and axes for movement.

- Feedback devices: Sensors (e.g., encoders, linear scales) that monitor tool/workpiece position and send data back to the controller for adjustments.

Step 1: Input the program

The process begins with loading a numerical control program (typically G-code or M-code) into the CNC controller. This program contains instructions for every movement and action, such as:

- Toolpath coordinates (e.g., “move to X=5.0, Y=3.0, Z=0.2”).

- Spindle speed, feed rate, and tool changes.

- Auxiliary functions (e.g., “turn on coolant” or “stop spindle”).

Programs are created using CAM software (as covered in “How does a CNC work step by step”) or manually coded for simple tasks.

Step 2: Decode and process the program

The CNC controller’s processor decodes the input program line by line, converting alphanumeric commands (e.g., G01 for linear interpolation) into machine-readable signals. It also:

- Checks for errors: Flags issues like invalid codes, impossible movements, or toolpath collisions.

- Optimizes execution: Adjusts the order of operations for efficiency (e.g., minimizing tool travel between cuts).

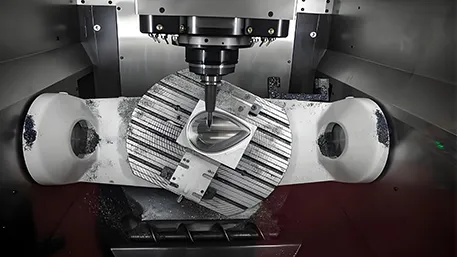

- Calculates intermediate positions: For complex curves (e.g., arcs defined by G02/G03 codes), the controller computes tiny linear segments to smooth the toolpath.

Step 3: Generate control signals

Once the program is validated, the controller converts decoded instructions into electrical signals for the machine’s drive systems. These signals specify:

- Axis movement: How far and fast each axis (X, Y, Z, etc.) should move, using values like velocity (inches per minute) and distance.

- Spindle and tool functions: Signals to start/stop the spindle, change tools, or activate coolant, sent to relays or servomotors controlling these components.

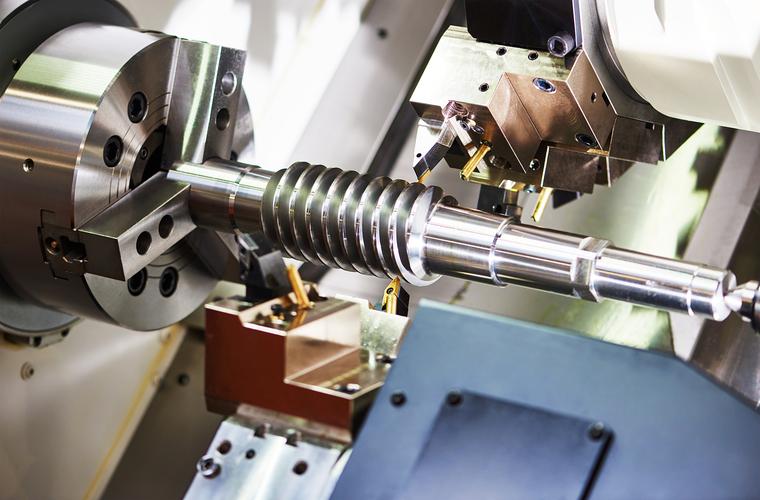

Step 4: Actuate the machine tool

The machine’s drive systems (servomotors or stepper motors) receive the controller’s signals and convert them into physical movement:

- Servomotors: Common in high-precision machines, they use feedback from encoders to adjust speed and position in real time, ensuring movements match the program exactly.

- Stepper motors: Move in fixed increments (steps) and are simpler but less precise, often used in entry-level CNC tools.

As motors rotate, they drive lead screws or ball screws to move the machine’s axes, positioning the cutting tool or workpiece along the programmed path.

Step 5: Monitor and adjust via feedback

Throughout operation, feedback devices (e.g., linear scales on axes or spindle encoders) measure the actual position, speed, and torque of moving components. This data is sent back to the controller, which:

- Compares actual values to the programmed ones.

- Makes micro-adjustments to correct errors (e.g., slowing the tool if it drifts off course).

- Triggers alarms for critical issues (e.g., excessive vibration, tool wear beyond limits) to prevent damage.

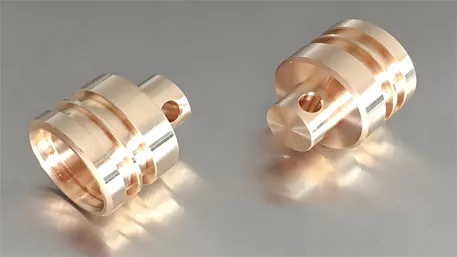

Step 6: Complete the cycle and reset

When the program finishes, the controller stops all movements, resets axes to a home position, and signals completion. The operator can then unload the finished part, load new material, and restart the process with the same or a new program.

Why is the CNC system’s coordination critical?

Every component—controller, drives, feedback devices—must work in sync to achieve precision. A delay in signal processing or a misalignment in feedback can lead to dimensional errors, tool breakage, or workpiece damage. Modern CNC systems (e.g., Fanuc, Siemens) use advanced algorithms to minimize latency, ensuring sub-millimeter accuracy even at high speeds.

Conclusion

A CNC system automates manufacturing by translating digital programs into precise mechanical actions, guided by real-time feedback. From program input to tool movement, each step relies on seamless communication between hardware and software, enabling the high accuracy and efficiency that make CNC technology indispensable in modern production.