- Tapping with a tap

- Principle: A tap (a tool with a complete thread profile) is driven by the spindle to rotate while feeding axially, directly cutting threads into the workpiece.

- Applicable scenarios: Internal thread machining (e.g., threaded holes), especially for small-diameter threads (usually ≤ M12), or scenarios pursuing efficiency in mass production.

- Advantages: Simple operation and convenient programming, suitable for small to medium-diameter threads.

- Thread milling

- Principle: A thread mill (single-tooth or multi-tooth) makes circular motion around the workpiece axis while feeding along the thread lead. Through the combination of the tool’s rotation and axial movement, the thread profile is gradually milled out.

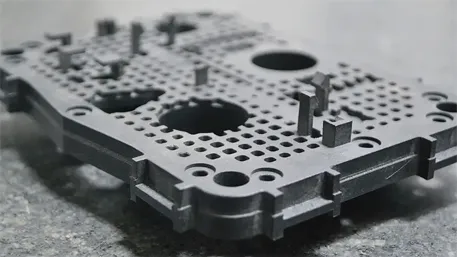

- Applicable scenarios: Large-diameter internal/external threads (e.g., M16 and above), precision threads (e.g., tolerance grades 6H/6g), or workpieces made of hard materials (e.g., stainless steel, titanium alloys).

- Advantages: High machining accuracy, long tool life, and the ability to machine threads of different rotation directions with a single program.

- Select tools and parameters

- Choose a corresponding tap (machine tap) according to the thread specification (e.g., M8×1.25), which needs to match the floating function of the tool holder to compensate for feed errors.

- Set parameters: Spindle speed (RPM) = (cutting speed × 1000) / (π × tap diameter); feed rate (mm/min) = spindle speed × pitch (e.g., the feed rate for M8×1.25 = speed × 1.25).

- Core programming instructions

- Use G84 (right-hand thread tapping cycle) or G74 (left-hand thread tapping cycle) to define the tapping process. Example code:

- Key point: The feed rate must strictly match the spindle speed and pitch; otherwise, thread disorder will occur.

- Execute machining

- After starting the program, the machine automatically completes: rapid movement to the thread starting point → spindle rotation and descent to the R point → tapping to the depth at the set feed rate → spindle reversal and withdrawal → return to the safe height.

- Select tools and parameters

- Choose a thread mill (with a diameter slightly smaller than the thread minor diameter; e.g., a φ8mm mill can be used for an M10 external thread) and set the cutting speed (e.g., 100-150m/min, adjusted according to the material).

- Core programming logic

- Thread milling requires controlling three movements: the circular motion of the tool around the workpiece (radius = thread pitch diameter / 2), axial feed (moving one pitch per circle), and tool rotation for cutting.

- Example code (simplified version):

- Key point: Ensure accurate thread lead through the linkage of circular interpolation (G02/G03) and axial feed.

- Avoid thread disorder: For tapping with a tap, the feed rate and speed must strictly match the pitch; for thread milling, the radius of the circular motion must be exactly equal to half of the thread pitch diameter.

- Cooling and lubrication: Cutting fluid (e.g., emulsion) must be used when machining steel workpieces; kerosene can be used for aluminum alloys to prevent tool overheating and wear.

- Thread inspection: After machining, check with thread gauges (go/no-go gauges) or use a coordinate measuring machine to detect parameters such as pitch diameter and thread angle.

- Tool clamping: Taps need to use floating tool holders to reduce tap breakage caused by machine axial errors; thread mills need to be rigidly clamped to ensure the accuracy of circular motion.

- For small-diameter, mass-produced internal threads → prioritize tapping with a tap (high efficiency);

- For large-diameter, precision, or hard-material threads → prioritize thread milling (high accuracy and low tool cost).