Brass is everywhere—from the faucet in your kitchen to the connectors in your smartphone, and even the valves in industrial machinery. This versatile alloy of copper and zinc has been prized for millennia for its durability, conductivity, and ease of shaping. But have you ever wondered: How is brass processed to transform raw metal into the precise parts we rely on? At Goldcattle, with 26 years of expertise in metal processing, we’ve mastered the art and science of brass machining. Let’s take a deep dive into the journey of brass—from its composition to finished components—and explore how Goldcattle delivers precision every step of the way.

What is Brass? The Foundation of Processing

Before diving into how brass is processed, it’s essential to understand what makes this alloy special. Brass is primarily composed of copper (60–90%) and zinc (10–40%), with small additions of other metals like lead (for machinability) or nickel (for corrosion resistance) in specific grades . This composition gives brass a unique set of properties:

- Excellent electrical conductivity (28–64% that of pure copper)

- High malleability (easily shaped without breaking)

- Good corrosion resistance (especially in non-saline environments)

- Low friction coefficient (0.2–0.3), making it ideal for moving parts like gears .

Common grades include C36000 (free-cutting brass), favored for CNC machining due to its chip-breaking properties, and C26000 (cartridge brass), known for its ductility in forming applications.

How is Brass Processed? The Step-by-Step Journey

Brass processing is a multi-stage process that transforms raw materials into functional parts, balancing precision, efficiency, and material properties. Here’s how it works:

1. Raw Material Preparation & Inspection

The process starts with high-quality brass billets, rods, or sheets sourced from certified suppliers. At Goldcattle, we rigorously inspect incoming materials using spectrometry to verify alloy composition—ensuring, for example, that C36000 brass contains exactly 61.5% copper, 35.5% zinc, and 3% lead as specified . This step prevents defects later in production, as impure brass can cause tool wear or part failure.

2. Cutting & Sizing

Brass stock is cut to rough dimensions using band saws or laser cutters, with tolerances of ±0.5mm to minimize material waste. For large production runs, we use automated cutoff machines that process 50+ pieces per minute—critical for meeting tight deadlines.

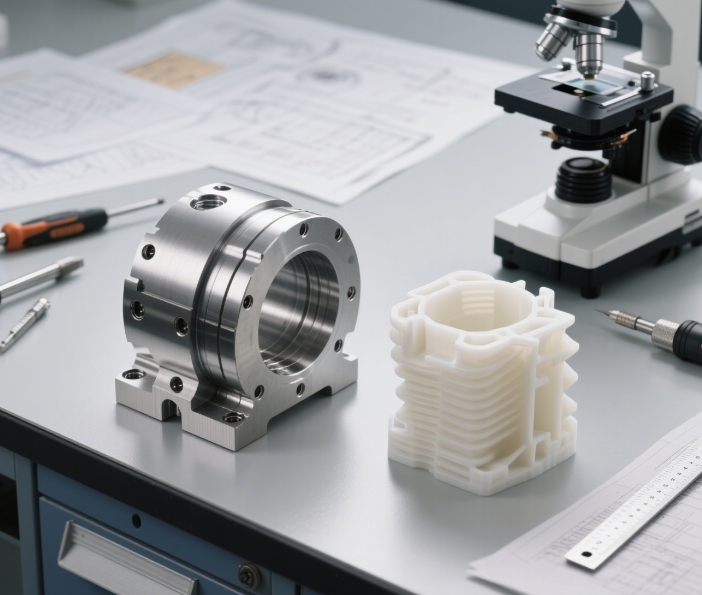

3. CNC Machining: Shaping Precision

The heart of modern brass processing is CNC machining, where computer-guided tools transform raw brass into detailed parts. Goldcattle uses two primary methods:

- CNC Turning: Ideal for cylindrical parts like bolts, bushings, and valve stems. Our lathes spin brass rods while stationary tools cut threads, grooves, or tapers, achieving tolerances as tight as ±0.001mm . A recent project for a plumbing client required 10,000 brass valve cores with 0.002mm concentricity to prevent leaks.

- CNC Milling: Perfect for flat or complex 3D parts such as electrical connectors or gear plates. Our 5-axis mills carve intricate features—like 0.5mm holes in sensor housings—with repeatable accuracy .

4. Deburring & Surface Finishing

Brass parts often have sharp edges or burrs after machining. We remove these using tumbling (for small parts) or abrasive brushing (for larger components) to ensure safety and proper fit. Surface finishes then enhance appearance and performance:

- Polishing: Creates a mirror-like finish (Ra 0.02μm) for decorative parts like musical instrument valves.

- Nickel plating: Adds corrosion resistance for marine or industrial applications.

- Passivation: Forms a protective oxide layer to prevent tarnishing in humid environments .

5. Heat Treatment (When Needed)

While brass is often used in its “as-machined” state, some applications require heat treatment to adjust hardness. For example, annealing at 600–700°C softens brass for further forming, while cold working (via rolling or drawing) increases tensile strength by up to 40% . Goldcattle’s controlled heat chambers ensure consistent results for critical parts like aerospace connectors.

6. Quality Control & Testing

No brass processing journey is complete without rigorous inspection. We use:

- CMM (Coordinate Measuring Machines) to verify dimensions, ensuring parts match CAD designs within ±0.001mm.

- Pressure testing for valve components, checking for leaks at up to 3,000 psi.

- Visual inspections under magnification to catch surface defects invisible to the naked eye.

This commitment to quality ensures Goldcattle’s brass parts meet ISO 9001 standards and client-specific requirements.

Applications: Where Processed Brass Shines

The versatility of processed brass makes it indispensable across industries:

- Electronics: Brass connectors and terminals leverage its conductivity—Goldcattle produces 500,000+ brass USB-C components yearly with 0.003mm pin alignment.

- Plumbing: Corrosion-resistant brass valves and fittings, machined to prevent leaks in residential and commercial systems.

- Automotive: Brass fuel line connectors and sensor housings, where precision prevents fuel leaks and ensures accurate readings.

- Musical Instruments: Polished brass valves and slides in trombones and trumpets, requiring smooth surfaces for airtight operation .

A recent highlight: Goldcattle partnered with a medical device firm to produce brass surgical instrument handles, achieving Ra 0.8μm surface finish to meet sterility standards and ensure a secure grip for surgeons.

Why Choose Goldcattle for Brass Processing?

- Expertise in Brass Grades: We know which grade (C36000, C26000, etc.) works best for your application—whether you need machinability, conductivity, or corrosion resistance.

- Advanced CNC Technology: Our 5-axis mills and Swiss-type lathes handle both micro-parts (0.5mm diameter) and large components (300mm length) with equal precision.

- Efficiency & Scalability: From 10-piece prototypes to 1,000,000-unit production runs, we optimize processes to reduce lead times (as fast as 5 days for prototypes).

- End-to-End Service: From material selection to finishing, we manage every step in-house, ensuring consistency and quality control.

FAQs: All About Brass Processing

Q: What’s the difference between machining brass and other metals like steel?

A: Brass is softer (Brinell hardness 60–100 vs. steel’s 120–300) and produces continuous chips, requiring specialized tooling to prevent “bird nesting” and ensure smooth cuts .

Q: What tolerances can you achieve in brass machining?

A: Our CNC machines regularly hit ±0.001mm for small parts, with larger components maintaining ±0.005mm—critical for tight-fitting assemblies.

Q: Can you process lead-free brass for potable water applications?

A: Yes! We specialize in lead-free grades like C69300 (copper-silicon alloy) that meet NSF/ANSI 61 standards for drinking water systems .

Q: How do you prevent brass from tarnishing during processing?

A: We use anti-tarnish coatings and control workshop humidity (40–50%) to protect parts during machining and storage.

Q: What’s the minimum order quantity for custom brass parts?

A: We accept orders as small as 1 piece for prototypes, scaling up to millions for production—no project is too big or too small.

Ready to Transform Brass Into Precision Parts?

Brass processing is a blend of science, technology, and craftsmanship—and Goldcattle brings all three to every project. Whether you need intricate electronic connectors or durable industrial valves, we have the expertise to turn your design into flawless brass components.

Visit https://www.xmgoldcattle.com/ to upload your CAD file or request a quote. Let’s craft brass parts that perform, last, and exceed your expectations.

Have a brass project in mind? Share your requirements below, and our brass processing experts will help you get started!