1. What Is CNC Cutting, and How Does It Differ From Traditional Cutting?

|

Feature

|

CNC Cutting

|

Traditional Manual Cutting

|

|

Accuracy

|

Repeatable (±0.005–0.02mm)

|

Dependent on operator skill (±0.1mm+)

|

|

Efficiency

|

Fast; ideal for high-volume or complex parts

|

Slow; limited by human speed

|

|

Consistency

|

Identical parts across batches

|

Variations between parts

|

|

Complexity

|

Handles intricate shapes (e.g., curved surfaces, holes)

|

Limited to simple geometries

|

2. Core Principles of CNC Cutting

- Computer Control System: The “brain” of the operation, typically a CNC controller (e.g., Fanuc, Siemens) that reads G-code (the programming language for CNC machines) and sends signals to the machine’s motors.

- Servo Motor System: Converts electrical signals from the controller into precise mechanical movement. Servo motors drive the machine’s axes (e.g., X, Y, Z for 3-axis machines; additional axes for 5-axis cutting) to position the tool or workpiece.

- Cutting Tool System: The tool (e.g., endmill, laser, plasma) that removes material. Tool selection depends on the material (e.g., metal vs. plastic) and desired finish (e.g., smooth edges vs. rapid cutting).

3. Step-by-Step Process of CNC Cutting

Step 1: Design the Part (CAD Modeling)

- Material Properties: The design must account for how the material behaves during cutting. For example, when designing a stainless steel medical instrument, you’ll need to leave extra space for “thermal expansion” (metal expands when heated by the tool) to avoid tight fits.

- Tolerance Specifications: Define acceptable deviations from the design (e.g., “hole diameter must be 10mm ±0.01mm” for aerospace parts). Use industry standards like ISO 8062 to ensure clarity.

- Machinability: Avoid features that are impossible or inefficient to cut. For instance, a 0.5mm-wide slot in a 20mm-thick aluminum block may require a specialized small-diameter endmill—otherwise, the tool could break.

Step 2: Convert Design to Machine Code (CAM Programming)

- Import the CAD File: The CAM software reads the CAD model (usually in formats like STEP or IGES) to analyze the part’s geometry.

- Select Cutting Strategy: Choose how the tool will remove material. Common strategies include:

-

- Contour Cutting: For shaping the outer edges of a part (e.g., cutting a circular disk from a metal sheet).

-

- Pocketing: For removing material from the inside of a part (e.g., creating a recess in a plastic housing).

-

- Drilling: For creating holes (e.g., mounting holes in a metal bracket).

- Optimize Tool Path: Adjust the path to minimize time and tool wear. For example, when cutting a complex curved part, the CAM software may use “high-speed machining” (HSM) to reduce vibration and improve surface finish.

- Generate G-Code: The software outputs a G-code file, which is saved to a USB drive or sent directly to the CNC machine via a network.

Step 3: Prepare the CNC Machine & Workpiece

- Install the Correct Tool: Mount the tool (e.g., endmill, laser head) in the machine’s spindle. Use a tool holder (e.g., a collet) to secure it tightly, and check for runout (vibration caused by a misaligned tool) with a dial indicator (runout should be <0.01mm).

- Secure the Workpiece: Clamp the material to the machine’s worktable using fixtures like:

-

- Vises: For small, rectangular parts (e.g., plastic blocks).

-

- Vacuum Tables: For thin materials (e.g., aluminum sheets) that can’t be clamped without damage.

-

- Custom Jigs: For irregularly shaped parts (e.g., curved metal brackets).

- Calibrate the Machine: Use a probe (a small sensor) to set the “work offset”—the position of the workpiece relative to the machine’s origin (0,0,0 point). This tells the machine where the part is located, ensuring cuts are made in the right place.

- Load the G-Code: Transfer the G-code file to the CNC machine and preview the tool path on the machine’s screen to check for errors (e.g., a tool path that goes outside the worktable).

Step 4: Execute the CNC Cutting Process

- The CNC controller reads the G-code line by line, sending signals to the servo motors to move the tool or workpiece along the programmed path.

- The spindle (or cutting tool) rotates at the speed set in the CAM program, and the tool moves at the feed rate to remove material.

- Coolant is often sprayed on the tool and workpiece to reduce heat (which can warp the material or damage the tool) and flush away chips (debris from cutting).

Step 5: Post-Cutting Inspection & Finishing

- Dimensional Checks: Use tools like calipers (for simple measurements), micrometers (for precise thickness checks), or a Coordinate Measuring Machine (CMM) (for complex 3D parts) to verify dimensions against the CAD model.

- Surface Finish Checks: Inspect the part’s surface for roughness (e.g., using a surface roughness tester) or defects (e.g., burrs, scratches).

- Deburring: Remove sharp edges or small pieces of material (burrs) using a file, sandpaper, or a deburring machine.

- Polishing: For parts that require a smooth surface (e.g., consumer electronics housings), use abrasive pads or chemical polishing.

- Coating: Apply a protective coating (e.g., anodizing for aluminum, powder coating for steel) to improve durability or appearance.

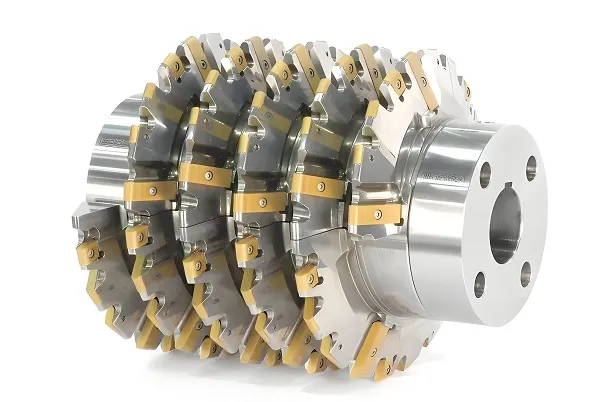

4. Common CNC Cutting Equipment Types

|

Equipment Type

|

How It Works

|

Best For

|

|

CNC Milling Machine

|

Uses rotating endmills to cut material (workpiece stays fixed, tool moves).

|

3D parts (e.g., plastic housings, metal brackets) in materials like aluminum, steel, wood.

|

|

CNC Lathe

|

Rotates the workpiece while a stationary tool cuts it (ideal for cylindrical parts).

|

Round parts (e.g., bolts, shafts, pipes) in metal or plastic.

|

|

CNC Laser Cutter

|

Uses a high-powered laser beam to melt/vaporize material.

|

Thin materials (0.1–20mm) like metal sheets, acrylic, wood, or fabric. Delivers smooth edges.

|

|

CNC Plasma Cutter

|

Uses a plasma arc (superheated gas) to cut through metal.

|

Thick metal (20–100mm) like steel, stainless steel, or aluminum. Fast, but less precise than lasers.

|

|

CNC Waterjet Cutter

|

Uses a high-pressure stream of water (mixed with abrasives) to cut material.

|

Heat-sensitive materials (e.g., glass, stone, titanium) or thick metals (up to 300mm). No heat damage.

|

5. Troubleshooting Common CNC Cutting Issues

|

Issue

|

Possible Cause

|

Solution

|

|

Cutting surface has burrs

|

Dull tool, low feed rate, or incorrect tool angle.

|

Replace the tool, increase feed rate, or adjust the tool’s cutting angle.

|

|

Part dimensions are off

|

Incorrect work offset, worn servo motors, or thermal expansion.

|

Re-calibrate the work offset, service the motors, or use coolant to reduce heat.

|

|

Tool breaks during cutting

|

Tool is too small for the material, high spindle speed, or loose tool holder.

|

Use a larger-diameter tool, reduce spindle speed, or tighten the tool holder.

|

|

Poor surface finish

|

Vibration (loose workpiece), dull tool, or low spindle speed.

|

Secure the workpiece tighter, replace the tool, or increase spindle speed.

|