1、Answer

The total time for injection molding varies widely:

- Single part cycle time: 10 seconds to 5+ minutes, depending on material (e.g., fast-cooling thermoplastics vs. slow-curing thermosets) and part complexity (e.g., thin walls vs. thick sections).

- Full production timeline: Includes mold design (2–12 weeks), machining (1–8 weeks), testing (1–2 weeks), and production (hours to months for millions of parts).

2、Expansion

Key Factors Influencing Injection Molding Time

-

Material Type

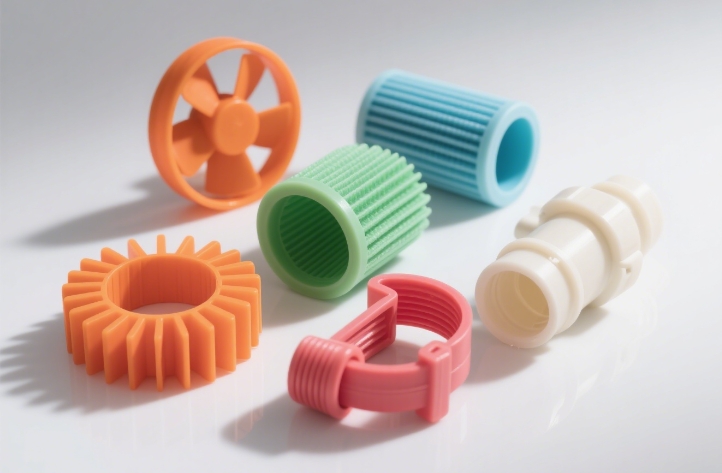

- Thermoplastics (e.g., ABS, PP): Short cycle times (10–60 seconds) due to rapid melting and cooling. Ideal for high-volume parts like bottle caps.

- Thermosets (e.g., epoxy, phenolic): Longer cycle times (2–5+ minutes) as they require heat and pressure to cure chemically, preventing re-melting. Used for electrical insulators or automotive components.

- Rubber/Vulcanized Materials: Require 2–10 minutes per cycle due to slower vulcanization (cross-linking) at high temperatures.

-

Part Geometry and Size

- Complex Parts: Intricate features (e.g., undercuts, thin walls, multi-cavity molds) increase cooling time and require precise mold design, adding 10–30% to cycle time.

- Large Parts: A car bumper (large surface area) may take 2–3 minutes to cool, while a small gear (1 cm³) cools in 30 seconds.

-

Mold Design and Cooling System

- Multi-Cavity Molds: Speed up production by making 2–128 parts per cycle (e.g., a 64-cavity mold for disposable cutlery reduces per-part time by 90% vs. single-cavity).

- Cooling Channels: Efficient mold cooling (via water/air channels) can halve cycle time. Poor design may trap heat, causing warping and extending cooling by 50% or more.

-

Production Scale

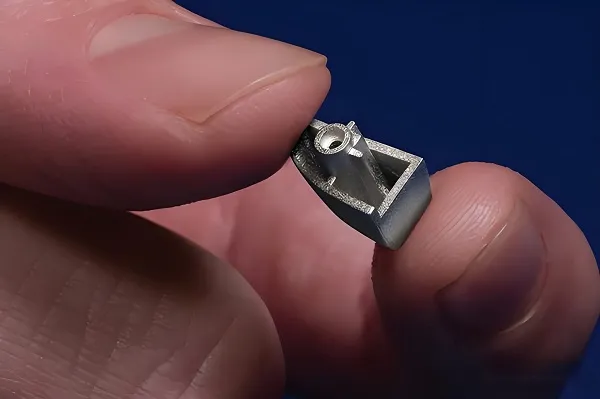

- Prototype/Mini-Run: Small batches (10–100 parts) may use 3D-printed or aluminum molds (faster to machine, 1–2 weeks) but have shorter mold lifespans (1,000–5,000 cycles).

- Mass Production: Steel molds (2–8 weeks to machine) last 500,000–1,000,000+ cycles, ideal for millions of parts (e.g., smartphone cases produced 24/7 with 20-second cycles).

Example Timelines for Different Projects

| Project Type | Mold Development Time | Cycle Time per Part | Total Production Time for 10,000 Parts |

|---|---|---|---|

| Simple plastic toy (ABS) | 4 weeks (aluminum mold) | 20 seconds | ~56 hours (including setup) |

| Complex automotive part (thermoset) | 12 weeks (steel mold) | 3 minutes | ~150 hours (excluding mold time) |

| Rubber gasket (EPDM) | 6 weeks (steel mold) | 90 seconds | ~250 hours |

Tips to Optimize Time

- DFM (Design for Manufacturing): Simplify part geometry (e.g., avoid sharp corners) to reduce cooling time and mold complexity.

- Pre-Heating Materials: Pre-drying hygroscopic resins (e.g., nylon) prevents moisture-related defects, avoiding rework delays.

- Automated Post-Processing: Integrate robotic trimming/deburring to reduce manual labor between cycles.

In short, injection molding’s speed depends on balancing material science, mold engineering, and production goals. While a single part can be made in seconds, the full process from design to millions of units requires careful planning, with mold development often being the longest upfront stage.