Answer

The time to CNC a part varies based on part complexity, material, equipment, and process. Simple parts (e.g., standard components) take minutes to 1 hour, while complex parts (e.g., molds, aerospace components) can take tens of hours or days, depending on detailed process planning and equipment capabilities.

Extended Response

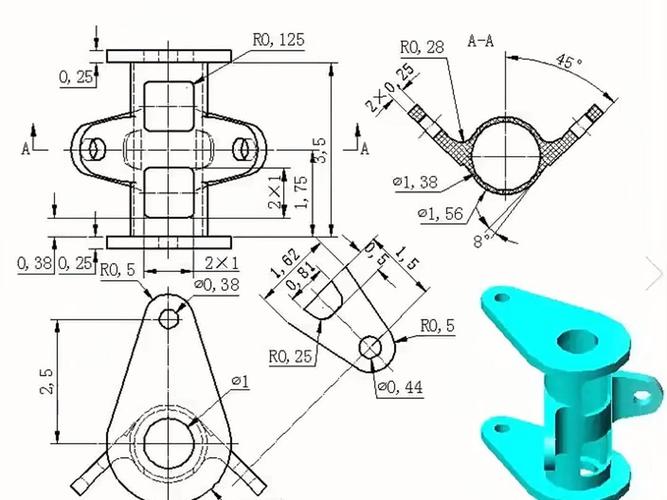

I. Part Complexity: Decisive Impact of Structure and Precision

-

Dimensional and Shape Complexity

- Simple structures: Regular parts like cubes or cylindrical pins, where processing time depends on material removal.

Example: Machining a 100mm×50mm×20mm aluminum block (5mm allowance removal) takes ~20 min for roughing and 10 min for finishing on a 3-axis mill, totaling <30 min. - Complex structures: Deep cavities, thin walls, or free-form surfaces (e.g., automotive panel molds) requiring multi-axis and layered machining.

Example: 5-axis milling of an impeller (200mm diameter, 2mm blade thickness) takes 4 hours for roughing (removing 90% material) and 6 hours for finishing (Ra≤1.6μm), totaling ~10 hours.

- Simple structures: Regular parts like cubes or cylindrical pins, where processing time depends on material removal.

-

Precision and Surface Requirements

- General precision (±0.1mm): Single-pass machining (e.g., one drilling for holes), accounting for ~30% of time.

- High precision (±0.01mm): Requires multi-stage processes (roughing→semi-finishing→finishing).

Example: Machining a precision bearing hole (Φ50H7) via drilling→reaming→honing takes 2-3x longer than general hole machining.

II. Material Properties: Core of Machinability and Efficiency

-

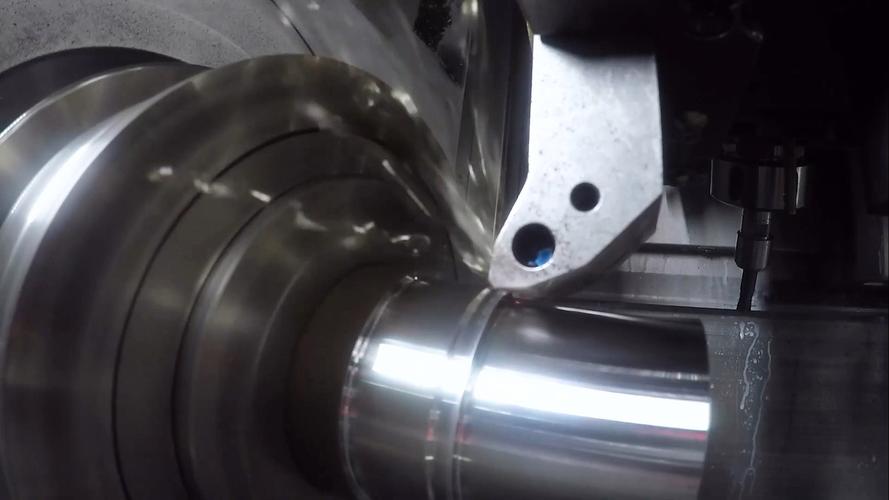

Hardness and Toughness

- Easy-to-cut materials: Aluminum (6061), brass, allowing high-speed machining.

Example: Milling a Φ100mm aluminum disc at 3000rpm spindle speed and 800mm/min feed takes ~15 min. - Difficult materials: Titanium (TC4), stainless steel (316L), requiring reduced parameters due to high cutting heat and tool wear.

Example: Same-sized TC4 disc needs spindle speed down to 1000rpm and feed to 300mm/min, extending time to 45 min with mid-process tool changes.

- Easy-to-cut materials: Aluminum (6061), brass, allowing high-speed machining.

-

Material Removal Rate (MRR)

- Formula: MRR = depth of cut × feed rate × cutting speed, directly impacting process time.

Example: Machining 45# steel (600MPa tensile strength) with a Φ16mm end mill at ap=3mm, F=500mm/min:

MRR ≈ 3×500×16 = 24,000mm³/min, removing 100cm³ takes ~4.2 min.

- Formula: MRR = depth of cut × feed rate × cutting speed, directly impacting process time.

III. Equipment and Process: Dual Constraints of Hardware and Flow

-

Machine Type and Axes

- 3-axis machines: Suitable for planar/simple contouring, lower efficiency.

Example: Machining a 100×80×50mm cuboid on a 3-axis mill takes ~1 hour with multi-face processing. - 5-axis machines: Complete complex surfaces in one setup, reducing clamping time.

Example: 5-axis machining of aerospace blades saves 40% time (from 8h to 4.8h) vs. 3-axis step-by-step processing.

- 3-axis machines: Suitable for planar/simple contouring, lower efficiency.

-

Process Route Planning

- Rational process splitting: E.g., drilling→tapping in separate steps requires tool changes and re-calibration (+5-10 min), while combined drill-tap tools reduce to 2 min.

- Cutting strategy: Climb milling is 30% more efficient than conventional milling (better surface finish, fewer finishing passes), and helical ramping reduces tool wear, enabling 10-20% higher feed rates.

IV. Programming and Simulation: Digital Time Costs

-

CAM Programming Efficiency

- Auto-programming: 5-10 min for simple parts in Mastercam, 2-4 hours for complex molds (including toolpath optimization).

- Manual programming: 1-2 min for simple contours (e.g., linear interpolation G-code), but double time for complex curves (e.g., ellipses).

-

Simulation and Debugging Time

- Software simulation (e.g., VERICUT) takes 5-30 min for collision/over-cut checks; machine debugging (tool setting, test cuts) may account for 20% of total time (e.g., 1-2 hours for complex parts).

V. Auxiliary Time: Invisible but Critical

-

Clamping and Tool Changes

- Standard clamping: 5-10 min for vise clamping, 15-30 min for special fixtures (e.g., 4-jaw chucks).

- Tool change frequency: 5-10 sec per change on machining centers, but 3-5 changes for multi-process parts (+1-2 min total).

-

Inspection and Post-Processing

- On-machine inspection: 3-5 min per key dimension check with built-in probes.

- Off-line CMM inspection: >30 min for complex parts, plus 1-3 hours for rework if unqualified.

VI. Batch Production and Optimization Strategies

-

Time Compression in Batch Processing

- Example: Machining 100 identical parts: 2-hour setup for the first piece, then 20 min per part afterward, totaling ~35 hours—30% more efficient than single-piece production.

-

Efficiency Optimization Methods

- High-Speed Cutting (HSC): Spindle speeds ≥10,000rpm boost aluminum machining efficiency by 50%, though equipment costs are high.

- Automation integration: Robot loading/unloading reduces manual clamping time, ideal for batches (e.g., saving 2 hours per batch in phone case machining).

- DFM (Design for Manufacturability): Simplifying structures (e.g., avoiding deep slots) shortens processing time by 20-40%.

VII. Case Studies: Time Comparison for Different Parts

| Part Type | Material | Dimensions | Precision | Equipment | Processing Time | Key Time Factors |

|---|---|---|---|---|---|---|

| Standard gear | 45# steel | Module 2, Φ80mm | ±0.05mm | 3-axis mill | 1.5 hours | Gear hobbing segmentation time |

| Medical device case | 6061 Al | 200×150×80mm | ±0.1mm | 5-axis VMC | 3 hours | Thin-wall layered milling for anti-deformation |

| Aero engine casing | TC4 titanium | 500mm diameter | ±0.02mm | 5-axis gantry mill | 48 hours | Difficult material + complex multi-surfaces |

Extended: Impact of Intelligent Technologies

- AI parameter optimization: FANUC’s AI spindle load control automatically adjusts speeds/feeds, reducing cycle time by 15-20%.

- Digital twin simulation: Virtual machine pre-processing predicts bottlenecks, cutting debugging time by >50%.

- Adaptive machining: Real-time cutting force monitoring dynamically adjusts parameters, avoiding rework and saving 10-30% time.

In summary, CNC processing time is a composite result of design, materials, equipment, and processes. Systematic optimization (DFM, efficient programming, equipment upgrades) is essential to balance time, precision, and cost.