Ask any engineer or project manager, and they’ll tell you: one of the most critical questions in manufacturing is, “How long does it take to CNC a part?” Whether you’re rushing a prototype for a product launch or scaling production for a large order, knowing the timeline keeps projects on track, budgets in check, and clients happy. The answer, however, isn’t one-size-fits-all—it depends on a mix of design complexity, materials, and machining strategy. At Goldcattle, with 26 years of CNC expertise, we’ve mastered the art of balancing speed and precision. Let’s break down the factors that shape CNC timelines, real-world examples, and how Goldcattle delivers efficient results without cutting corners.

The Big Picture: What Determines CNC Part Time?

CNC machining timelines range from 30 minutes for a simple aluminum spacer to 10+ hours for a complex aerospace component—and even longer for oversized parts. The key is understanding the variables that add time to the process. Think of it like baking a cake: a basic cookie takes minutes, but a multi-layered wedding cake needs hours of careful work. Similarly, CNC part time depends on five core factors:

1. Part Complexity: Simple vs. Intricate Designs

A part with basic geometry—like a flat aluminum plate with a few holes—will machine quickly because it requires minimal tool changes and straightforward toolpaths. For example, a 50mm × 50mm aluminum bracket with 4 holes might take just 45–60 minutes on a 3-axis CNC mill.

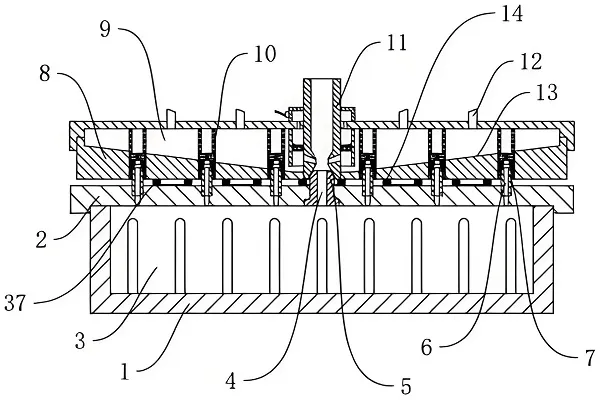

Complex parts, however, demand more time. Imagine a titanium aerospace fitting with curved surfaces, internal threads, and tight tolerances (±0.002mm). These require 5-axis CNC machining, where the machine rotates the part while cutting, and multiple tool changes (end mills, drills, taps). Such a part could take 3–5 hours to complete as the CNC program navigates intricate paths without errors .

2. Material: Harder Materials Mean Slower Speeds

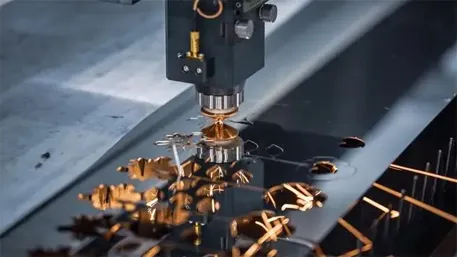

Different materials resist cutting in unique ways, directly impacting machining time. Soft materials like aluminum (6061) and brass cut quickly because their low hardness (60–100 HB for aluminum) allows faster spindle speeds (up to 15,000 RPM) and feed rates. A brass electrical connector might machine in 20–30 minutes.

Harder materials like stainless steel (316) or titanium (Ti-6Al-4V) require slower speeds to protect tools from wear. Titanium, with a hardness of 300–350 HB, often needs spindle speeds below 5,000 RPM and lighter cuts. A titanium medical implant with similar size to the brass connector could take 2–3 hours—6x longer—due to slower material removal rates .

3. Machine Type: 3-Axis vs. 5-Axis Efficiency

The CNC machine itself plays a big role. 3-axis machines (X, Y, Z axes) are great for simple parts but require repositioning the part for multi-sided cuts, adding setup time. A 3-axis mill might need 2–3 setups for a part with features on 3 sides, each adding 15–20 minutes.

5-axis CNC machines eliminate this hassle by rotating the part (A and C axes) while cutting, allowing multi-sided machining in a single setup. A 5-axis machine can reduce setup time by 40–60% for complex parts. For example, a drone frame with curved surfaces that takes 2 hours on a 3-axis machine might finish in 1 hour 15 minutes on a 5-axis mill at Goldcattle .

4. Batch Size: Prototypes vs. Production Runs

Timelines shift dramatically between prototyping and mass production:

- Prototypes (1–10 parts): Even simple prototypes need setup time for programming, material loading, and first-article inspection. A single prototype might take 1–3 days from design to delivery, with actual machining time as low as 1 hour but planning and QA adding time.

- Production Runs (100–10,000 parts): Once the CNC program is optimized, production speeds up. Goldcattle’s automated cells, for example, can run 100 aluminum brackets in 8–10 hours (vs. 2 hours per part for prototypes) by minimizing tool changes and loading/unloading downtime .

5. Tolerances and Finishes: Precision Takes Time

Tight tolerances (±0.001mm vs. ±0.05mm) require slower, more controlled cuts to avoid errors. A part needing a mirror-like surface finish (Ra 0.02μm) will take longer than one with a standard finish (Ra 1.6μm) because it requires multiple passes with finer tools. For example, a stainless steel valve body with high-precision sealing surfaces might add 30–60 minutes of finishing time compared to a basic version .

Real-World Examples from Goldcattle

Example 1: Simple Aluminum Prototype

- Part: 100mm × 50mm aluminum (6061) bracket with 2 holes and a slot

- Machining Time: 45 minutes

- Total Lead Time: 2 days (including design review and QA)

Example 2: Complex Titanium Aerospace Part

- Part: 75mm titanium (Ti-6Al-4V) fitting with curved surfaces and internal threads

- Total Lead Time: 5 days (including material sourcing and 100% inspection)

Example 3: High-Volume Brass Electrical Connectors

- Part: 20mm brass (C36000) connectors, batch of 500

- Machine: Automated 4-axis CNC lathe

- Per-Part Machining Time: 3 minutes

- Total Lead Time: 7 days (including setup, production, and sampling)

How Goldcattle Optimizes CNC Timelines

At Goldcattle, we don’t just estimate timelines—we actively reduce them while maintaining quality:

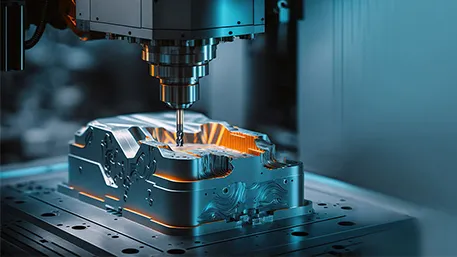

- Advanced Programming: Our engineers use CAD/CAM software with AI-powered toolpath optimization, cutting cycle times by 15–20% for complex parts.

- 5-Axis Machining: With 12+ 5-axis machines, we eliminate multiple setups, slashing lead times for intricate designs.

- Material Readiness: We stock common materials (aluminum, stainless steel, brass) to reduce sourcing delays—critical for prototypes.

- Automation: Robotic loading/unloading systems run lights-out production, doubling output for high-volume orders without adding labor time.

- DFM Expertise: Early Design for Manufacturability feedback simplifies geometries where possible, avoiding unnecessary machining steps.

FAQs: Your CNC Timeline Questions Answered

Q: What’s the fastest a CNC part can be produced?

A: Simple prototypes (like basic aluminum brackets) can be machined in as little as 30 minutes with expedited service, with total delivery in 1–2 days.

Q: Why does material type affect time so much?

A: Harder materials require slower cutting speeds to prevent tool wear. For example, titanium machines at 10–20% the speed of aluminum for the same part size .

Q: Does batch size reduce per-part time?

A: Yes! Production runs benefit from optimized setups. A batch of 100 parts often has 50% lower per-part time than a single prototype.

Q: How do tolerances impact timeline?

Tighter tolerances (±0.001mm) can add 20–30% to machining time due to slower feeds, finer tools, and more frequent measurements.

Q: Can Goldcattle rush urgent orders?

A: Absolutely. Our “Rapid Response” service prioritizes urgent projects, with prototypes sometimes delivered in 24–48 hours using in-stock materials and dedicated machines.

Ready to Get Your CNC Timeline Estimate?

Knowing “how long does it take to CNC a part” starts with your unique design, material, and volume needs. At Goldcattle, we combine technical expertise with advanced technology to deliver accurate timelines and efficient results—whether you need a single prototype or 10,000 production parts.

Upload your CAD file at https://www.xmgoldcattle.com/ for a free timeline estimate, or reach out to our team to discuss your project. Let’s get your parts machined on time, every time.

Got a specific part in mind? Share your design details below, and our engineers will provide a personalized timeline!