In the manufacturing industry, Computer Numerical Control (CNC) machining is widely used for producing various precision parts. Whether it’s product research and development in small enterprises or mass production in large factories, understanding the cost composition of CNC parts is crucial for effective budget control and enhanced production efficiency. So, how much does a CNC part actually cost? The answer to this question is not straightforward, as it is influenced by numerous factors.

Key Factors Affecting the Cost of CNC Parts

Raw Material Costs

Raw materials constitute a significant portion of the cost of CNC parts. The prices of different materials vary greatly, ranging from common metals such as aluminum, copper, and steel, to special metals like titanium alloys, as well as various plastics and composite materials. Taking metals as an example, aluminum is relatively affordable. In particular, 6061 aluminum alloy is widely used in CNC machining due to its excellent machining properties and moderate price. In contrast, titanium alloys are often used in high – end fields such as aerospace and medical applications because of their superior strength – to – weight ratio, corrosion resistance, and high – temperature performance. However, their prices are also significantly higher, possibly several times or even more than that of aluminum.

In addition to the type of material, the specifications and quality of the material also affect the cost. Larger – sized or special – specification raw materials usually require higher procurement costs. Moreover, for some application scenarios with extremely high material quality requirements, such as medical implants or aerospace engine components, high – quality materials that meet strict standards must be used, which significantly increases the cost. For example, in the aerospace field, the high – temperature alloys used to manufacture engine blades are not only expensive but also have relatively limited procurement channels, further driving up the raw material cost.

Machining Complexity

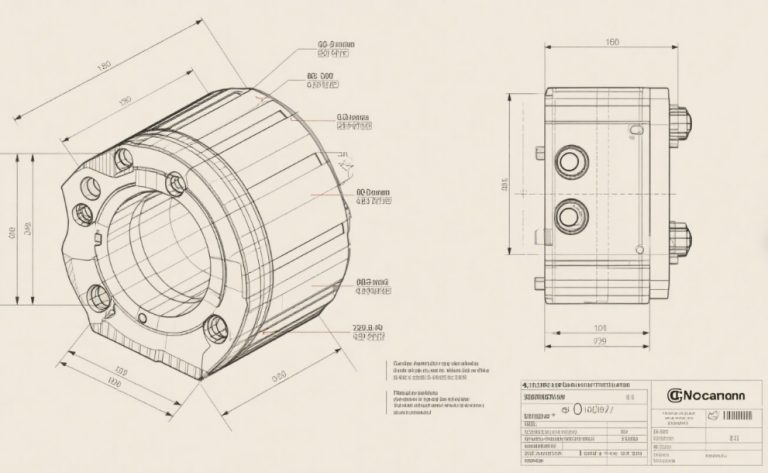

The design complexity of the part is another key factor determining the cost of CNC machining. Simple geometric shapes, such as cuboids and cylinders, have a relatively straightforward machining process, requiring fewer machining steps and less time, resulting in lower costs. On the contrary, complex shapes, such as parts with irregular curved surfaces, intricate internal structures, or tiny features, demand more complex machining processes and higher programming skills.

Take a mold with complex curved surfaces as an example. To achieve precise curved surface machining, a multi – axis CNC machine may be required, and complex tool path planning is necessary. This not only increases the difficulty and time of programming but may also require the use of special tools and work – holding fixtures, thus significantly increasing the machining cost. In addition, the risk of scrap is relatively higher during the machining of complex parts. Once a scrap occurs, re – machining is required, further increasing the cost.

Machining Time

Machining time is one of the direct determinants of the cost of CNC parts. CNC machining is usually charged according to machining time; the longer the machining time, the higher the cost. Machining time mainly depends on the complexity of the part, its size, and the machining process used.

For complex parts, since more machining operations are required, such as multiple tool changes and multi – pass cutting, the machining time will increase significantly. For example, a part that requires multiple machining operations such as precision milling, drilling, and tapping will definitely take much longer to machine than a part that only requires simple milling. In addition, the size of the part also affects the machining time. Larger parts usually require longer cutting paths and more machining time to complete the processing.

Tolerance and Surface Quality Requirements

Tolerance requirements and surface quality standards have an important impact on the cost of CNC parts. Strict tolerance requirements mean that higher precision control is needed during the machining process, which may require the use of higher – precision machine tools, more advanced measuring equipment, and more experienced operators. For example, when manufacturing precision components for aerospace engines, the tolerance requirements may reach the micrometer level. To meet such high – precision requirements, enterprises need to invest a large amount of capital in equipment upgrades and personnel training, thereby increasing the machining cost.

Similarly, parts with high surface quality requirements, such as those requiring mirror polishing or special surface treatments, will also increase the machining cost. Surface treatment processes, such as electroplating, anodizing, and painting, not only require additional equipment and materials but also require strict control of the process parameters to ensure the desired surface quality. All these will undoubtedly increase the total cost of the parts.

Batch Size

Batch size is an important factor affecting the cost of CNC parts. Generally, the larger the batch size, the lower the cost per part. This is because in mass production, the upfront preparation costs, such as programming costs and the cost of making work – holding fixtures, can be spread over more parts.

Take a simple mechanical part as an example. Suppose the cost of making a set of work – holding fixtures is (1000. If only 10 parts are produced, the cost of the work – holding fixtures allocated to each part is )100. However, if 1000 parts are produced, the cost of the work – holding fixtures allocated to each part drops to $1. In addition, mass production can also improve production efficiency and reduce the scrap rate, further reducing the cost per part.

Calculation Methods for the Cost of CNC Parts

Although the cost of CNC parts is affected by many factors, it can usually be calculated using the following basic formula:

(Total Cost = Raw Material Cost+Machining Cost + Post – processing Cost+Indirect Cost+Profit)

Calculation of Raw Material Costs

The calculation of raw material costs is relatively straightforward and mainly depends on the unit price and quantity of the materials used. The quantity of materials can be accurately calculated based on the design dimensions and shape of the part. Considering the losses during the machining process, the actual purchase quantity is usually slightly larger than the theoretical quantity. The unit price of the material is determined according to market conditions and supplier quotes. For example, if an aluminum alloy material with a price of (50 per kilogram is used to machine a part, and the part requires 0.5 kilograms of material, considering a 10% machining loss, 0.55 kilograms of material actually need to be purchased. Then the raw material cost of this part is )0.55×50 = $27.5.

Calculation of Machining Costs

Machining costs mainly include equipment usage costs, labor costs, and tool wear costs. Equipment usage costs are usually calculated based on the hourly machining cost of the machine tool. The hourly machining costs of different types and precision levels of machine tools vary greatly. For example, the hourly machining cost of an ordinary 3 – axis CNC milling machine may be between (50 – )100, while the hourly machining cost of a high – precision 5 – axis CNC machining center may be as high as (500 – )1000.

Labor costs depend on the skill level of the operators and their salary. For the machining of complex parts, experienced senior technicians may be required for operation, and their salary level is relatively high. Tool wear costs are related to the service life and price of the tools. Different types of tools, such as milling cutters, drill bits, and taps, have different service lives and prices. When calculating the machining cost, these factors need to be comprehensively considered. Suppose a part needs to be machined on a 3 – axis CNC milling machine for 2 hours, the hourly machining cost is (80, the operator’s salary is )50 per hour, and the tool wear cost is (20. Then the machining cost of this part is )(80 + 50)×2+20 = $280.

Calculation of Post – processing Costs

Post – processing costs include the costs of part surface treatment, assembly, packaging, etc. The surface treatment cost varies according to the surface treatment process used. For example, the cost of simple sandblasting treatment is relatively low, possibly only a few dollars per part. In contrast, the cost of complex electroplating or anodizing treatment is higher, possibly tens or even hundreds of dollars per part. Assembly costs depend on the complexity of part assembly and the required labor time. Packaging costs vary according to the packaging materials and packaging methods. Suppose a part requires anodizing treatment at a cost of (50, assembly cost of )30, and packaging cost of (10. Then the post – processing cost of this part is )50 + 30+10 = $90.

Calculation of Indirect Costs

Indirect costs include enterprise management fees, equipment depreciation fees, utility bills, etc. Although these costs are not directly related to the machining of a single part, they need to be allocated to each part. The allocation method of indirect costs is usually determined according to the enterprise’s cost accounting system and can generally be allocated according to machining time, material cost, or product quantity. Suppose the monthly indirect cost of an enterprise is (100,000, and the total machining time of the parts produced in that month is 1000 hours. Then the indirect cost allocated per hour is )100. If the machining time of a part is 2 hours, the indirect cost allocated to this part is (2×100 = )200.

Calculation of Profits

Profit is an important goal of enterprise production and operation. CNC machining enterprises usually add a certain profit margin to the cost to determine the product price. The level of the profit margin depends on market competition, the enterprise’s business strategy, and the added value of the product. Generally, the profit margin of ordinary CNC parts may be between 10% – 20%, while for some parts with high technical content and tight market demand, the profit margin may be higher. Suppose the total cost of a part is (600, and the enterprise sets a profit margin of 15%. Then the profit of this part is )600×15%=(90, and the selling price is )600 + 90 = $690.

Strategies for Reducing the Cost of CNC Parts

Design Optimization

Fully considering the processability of CNC machining in the product design stage can effectively reduce machining costs. Simplify the design of parts, avoid overly complex shapes and structures, and reduce unnecessary machining features. For example, try to use regular geometric shapes and reduce the design of irregular curved surfaces. Reasonably design the dimensions and tolerances of parts to avoid excessive precision requirements. At the same time, adopt the modular design concept, decompose complex parts into multiple simple modules for machining and assembly, which can improve machining efficiency and reduce the scrap rate.

Selection of Appropriate Materials

On the premise of meeting the performance requirements of the parts, select materials with reasonable prices and good machining properties. The prices and machining difficulties of different materials vary greatly. Through a comprehensive evaluation of material performance and cost, select materials with high cost – effectiveness. For example, for some parts with low strength requirements, aluminum alloy materials can be selected instead of steel materials to reduce material costs and machining difficulties. In addition, pay attention to market conditions of materials, purchase materials reasonably, and avoid cost increases caused by material price fluctuations.

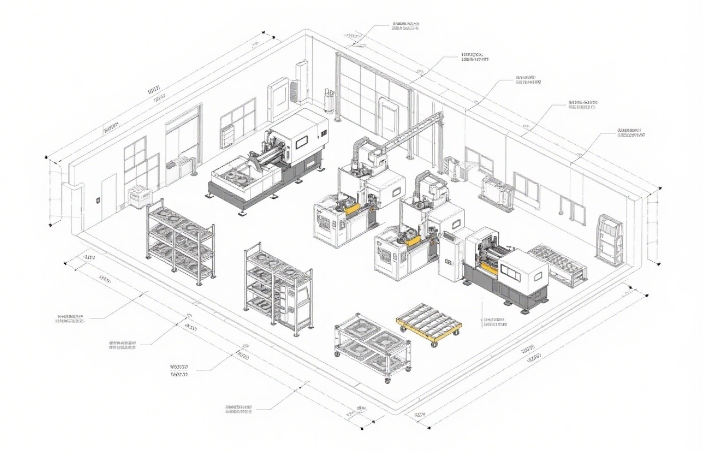

Improvement of Machining Efficiency

Optimize the machining process, select appropriate machining equipment and tools to improve machining efficiency and shorten machining time. Adopt advanced machining technologies, such as high – speed cutting and multi – axis machining, which can significantly increase the machining speed while ensuring machining quality. At the same time, reasonably arrange the machining sequence, reduce unnecessary clamping and tool change times, and improve the utilization rate of equipment. For example, using a compound machining machine can complete multiple machining operations on one machine, reducing the handling and clamping time of parts between different machines.

Mass Production

Make full use of the advantages of mass production to reduce the cost per part by increasing the production batch. In mass production, the upfront preparation costs can be spread over more parts. At the same time, the production process can be optimized, production efficiency can be improved, and the scrap rate can be reduced. Establish long – term and stable cooperative relationships with suppliers to obtain more favorable purchase prices and better services, further reducing costs.

Case Studies

Case 1: Simple Aluminum Alloy Parts

An enterprise needs to machine a batch of simple aluminum alloy brackets. The part shape is a cuboid with dimensions of 100mm×50mm×20mm, made of 6061 aluminum alloy, with a tolerance requirement of ±0.1mm and a surface requirement of sandblasting treatment. Since the part shape is simple and the machining process is relatively straightforward, a 3 – axis CNC milling machine can be used to complete the machining. According to the calculation, the raw material cost of each part is about (10, the machining time is 0.5 hours, the hourly machining cost is )80, the surface treatment cost is (5, and the allocated indirect cost is )50. Calculated according to a 15% profit margin, the cost of each part is (10+0.5×80 + 5+50=)105, and the selling price is (105×(1 + 15%)=)120.75.

Case 2: Complex Stainless Steel Parts

Another enterprise needs to machine a complex stainless – steel part for medical devices. The part has irregular curved surfaces and intricate internal structures, made of 316L stainless steel, with a tolerance requirement of ±0.05mm and a surface requirement of mirror polishing. Due to the high complexity of the part, a 5 – axis CNC machining center is required for machining, and special tools and work – holding fixtures are needed. After calculation, the raw material cost of each part is about (100, the machining time is 8 hours, the hourly machining cost is )600, the surface treatment cost is (100, and the allocated indirect cost is )200. Calculated according to a 20% profit margin, the cost of each part is (100+8×600 + 100+200=)5300, and the selling price is (5300×(1 + 20%)=)6360.

Through the above two cases, it can be clearly seen that factors such as part complexity, material selection, machining process, and tolerance and surface quality requirements have a huge impact on the cost of CNC parts. In actual production, enterprises need to comprehensively consider various factors according to specific situations and formulate reasonable cost – control strategies to improve the market competitiveness of products.

In conclusion, the cost of CNC parts is a complex issue affected by many factors. Through in – depth understanding and analysis of these factors, enterprises can take effective measures in product design, material selection, and machining process optimization to reduce the cost of CNC parts and improve production efficiency. At the same time, when cooperating with CNC machining suppliers, enterprises should provide detailed and accurate part design drawings and technical requirements so that suppliers can give reasonable quotes and ensure that projects are carried out smoothly within the budget.