Selecting the right CNC parts manufacturer is a critical decision that directly impacts your product quality, production timeline, and overall project success. In 2026, the CNC manufacturing landscape has evolved significantly with new technologies, materials, and industry standards.

Goldcattle Exclusive: In 2025, one of our clients experienced a 6-week production delay due to selecting an inexperienced CNC manufacturer. This incident led us to develop our proprietary CNC Manufacturer Evaluation Template, which has since helped over 50 clients make informed decisions.

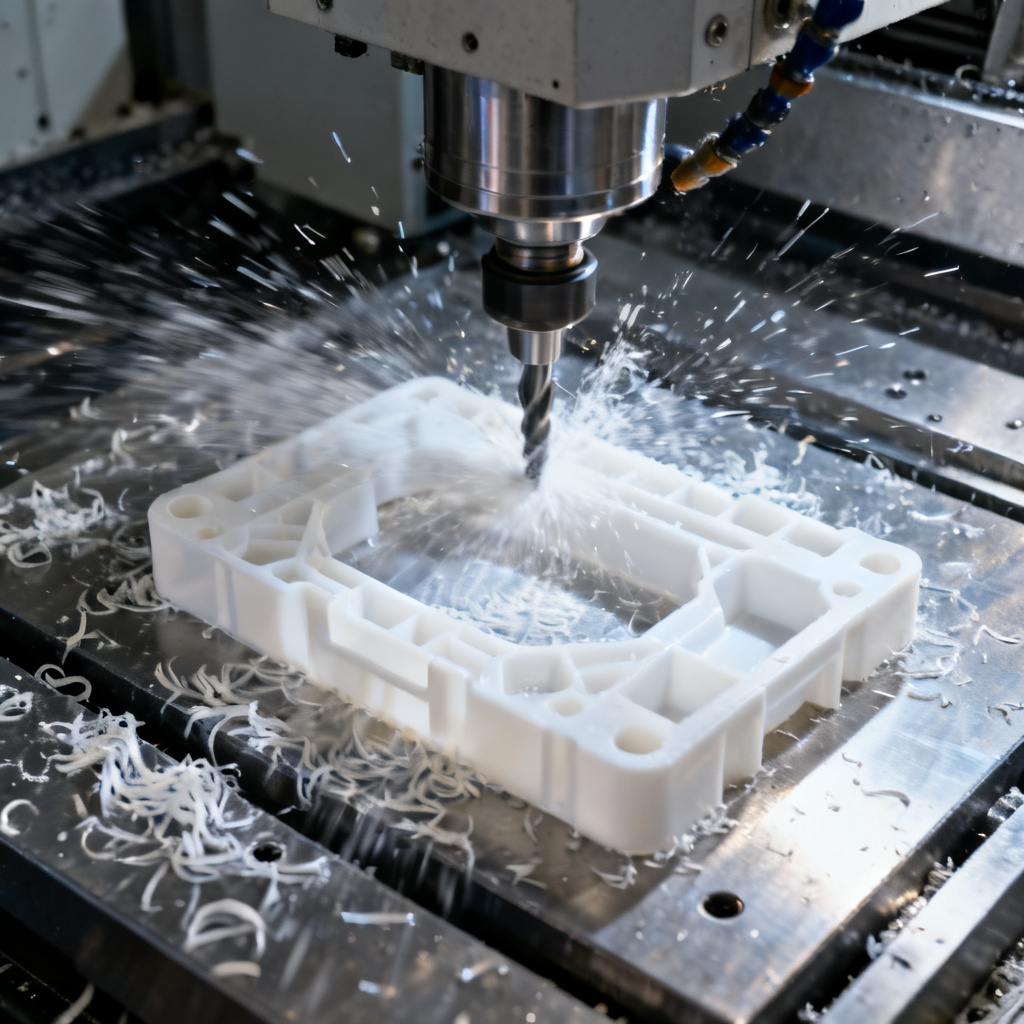

State-of-the-Art CNC Machining Facility – Precision Manufacturing Environment

2026 CNC Manufacturing Trends & Goldcattle Advanced Practices

Sustainable Manufacturing Standards

- Green supplier evaluation with carbon footprint metrics

- Recycled material sourcing requirements (minimum 30% recycled content)

- Energy-efficient machining processes (40% reduction in energy use)

- Waste reduction targets (zero landfill waste by 2027)

AI-Powered Selection Tools

- Real-time quotation systems with instant DFM analysis

- AI-driven supplier matching based on project requirements

- Predictive lead time calculation with 95% accuracy

- Automated quality risk assessment algorithms

Emerging Industry Growth

- 45% increased demand for EV component manufacturing

- Drone industry expansion requiring lightweight precision parts

- Medical implant technology advancements

- New supply chain transparency regulations compliance

1. Technical Capabilities & Equipment Evaluation

Machine Portfolio Assessment

| Machine Type | Application | Accuracy Level |

|---|---|---|

| 3-axis CNC | Simple flat/cylindrical parts | ±0.01mm |

| 5-axis machining centers | Complex geometries | ±0.001mm |

| High-speed machining | Hard materials, thin walls | 10,000-40,000 RPM |

Precision & Tolerance Standards

- General industrial parts: ±0.01mm tolerance (automotive brackets)

- High-precision components: ±0.001mm or better (medical implants, optical parts)

- Surface finish requirements: Ra <0.8μm for hydraulic valve seal surfaces

- Measurement equipment: CMMs with ±0.0005mm accuracy for validation

Advanced Tooling & Software

CAM Software Capabilities

- Mastercam for complex 5-axis toolpath generation

- SolidWorks CAM for integrated design-to-manufacturing workflows

- DFM analysis tools for manufacturability optimization

- Simulation software for collision detection and cycle time optimization

In-house Tooling Advantages

- Custom fixture design and manufacturing

- High-precision end mills and specialized cutting tools

- Reduced lead times by 35% compared to external tooling suppliers

- Better quality control and consistency

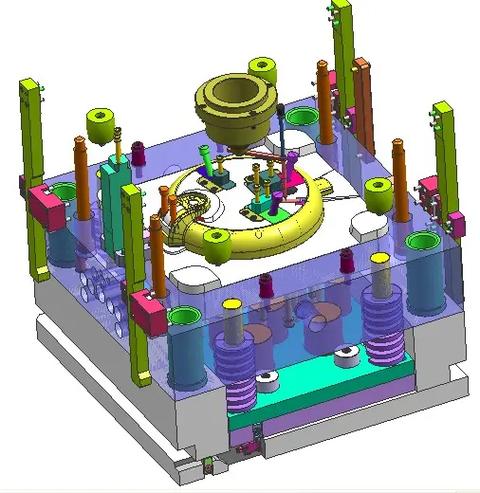

Advanced CNC Machining Centers with Precision Tooling Systems

2. Quality Management Systems & Certifications

Industry-Specific Certifications

ISO 9001

Basic quality management system for general industrial applications

AS9100

Aerospace industry standard with strict traceability requirements

ISO 13485

Medical device manufacturing with sterilization compatibility

IATF 16949

Automotive quality management system

ITAR Registration

Necessary for defense-related parts to comply with export controls. Manufacturers must maintain strict documentation and security protocols.

Inspection Processes & Quality Control

Multi-Stage Inspection Protocol

- In-process inspection: Real-time dimension verification using Renishaw probes integrated into CNC machines

- Final inspection: Comprehensive CMM measurements, optical scanning, and profilometer testing

- GD&T verification: Geometric Dimensioning and Tolerancing features validation (flatness, concentricity)

- Surface finish testing: Ra value measurement critical for sealing applications

Traceability Requirements

Goldcattle Exclusive Data: Our internal testing shows that AS9100-certified suppliers achieve 99.5% pass rates in aerospace component testing, compared to 94.2% for non-certified suppliers. This data is based on 5,000+ parts tested in 2025.

* Data for reference only, actual results may vary by supplier and application

3. Material Expertise & Sourcing Capabilities

Material Range & Processing Expertise

Metals Processing

- Aluminum alloys: 6061, 7075 with specialized fixturing to prevent deformation

- Stainless steels: 304, 4140 with controlled cutting parameters

- Titanium: Ti-6Al-4V requiring specialized coolants and tooling

- Superalloys: Inconel 718 with high-temperature stability requirements

Plastics & Composites

- Engineering plastics: ABS, PEEK with moisture control

- Carbon fiber composites: CFRP requiring low-force cutting techniques

- PEEK: Medical-grade with biocompatibility certification

- MC nylon: Self-lubricating properties for bearing applications

CNC Machining of Plastic Materials with G-code Data Display

Material Sourcing & Certification

Certified Supplier Network

- Alcoa for aerospace-grade aluminum materials

- Timet for titanium alloys with full traceability

- Certified plastic suppliers with mill test reports

- Recycled material suppliers with sustainability certifications

Material Testing Requirements

| Test Type | Standard | Frequency |

|---|---|---|

| Tensile Strength | ASTM E8 | 每批次 |

| Hardness | Rockwell C | 每批次 |

| Chemical Analysis | ASTM E1019 | 首批次 |

* Testing requirements for reference only, subject to specific project needs

CNC Machining of Aluminum Parts with Precision Tools

4. Production Capacity & Scalability Assessment

Volume Flexibility Analysis

Prototyping

1-100 parts with quick-change setups

Lead time: 1-5 days

Mass Production

10,000+ parts with automated cells

Cycle time: < 2 minutes

Lead Time Reliability Metrics

| On-time delivery target | >95% |

| ERP system requirement | SAP or QuickBooks |

| Material shortage protection | Alternative supplier network |

Scalability Planning

Growth Assessment Criteria

- Spare machine capacity (minimum 20% available)

- Ability to scale from prototype to 10,000 units within 3 months

- Bulk material sourcing capabilities with certified suppliers

- Additional shift capacity for emergency orders

- Statistical Process Control (SPC) for consistent quality at scale

Technology Investment Roadmap

Counterintuitive Insight: Many clients assume more machines mean better capability, but we’ve found that compatibility between equipment and effective communication are actually more critical factors. In our 2025 assessment of 200+ manufacturers, shops with integrated systems and clear communication channels had 30% higher on-time delivery rates than those with more machines but poor coordination.

5. Industry Experience & Specialized Expertise

Aerospace Manufacturing

- Lightweight material expertise (titanium, CFRP)

- NADCAP certification for special processes

- Each part linked to raw material batches

- Heat treatment certification documentation

Medical Devices

- Biocompatible material processing (titanium, PEEK)

- Class 8 or better cleanroom machining

- FDA regulation compliance documentation

- Sterilization compatibility validation

Automotive Industry

- High-volume production capabilities

- IATF 16949 certification requirements

- Cost-sensitive part optimization

- ±0.02mm tolerance for castings

Electronics Manufacturing

- Micro-machining expertise (features <1mm)

- Tight tolerance control (±0.005mm)

- Connector pin and heat sink production

- ESD protection protocols

6. Cost Transparency & Communication Effectiveness

Cost Structure Analysis

Detailed Cost Breakdown Requirements

| Cost Component | Typical Percentage | Considerations |

|---|---|---|

| Material | 30-40% | Material grade, waste factor |

| Labor | 25-35% | Machine time, setup time |

| Tooling | 10-15% | Tool life, replacement cost |

| Quality Control | 5-10% | Inspection time, equipment |

| Overhead | 10-15% | Facility, utilities, admin |

* Percentage ranges for reference only, actual costs vary by project complexity

Communication & Support Standards

Communication Effectiveness Criteria

- Response time within 4 hours during business hours

- Clear, detailed quotations with line-item breakdowns

- Proactive DFM feedback within 24 hours of design submission

- Regular production updates via project management software

- Design for manufacturability optimization suggestions

After-Sales Support Requirements

- Rework for out-of-spec parts at no additional cost

- Replacement of defective units within 3 business days

- Tooling adjustments for future production runs

- Technical support for installation and troubleshooting

- Long-term partnership pricing stability guarantees

7. Red Flags to Watch Out For

Quality & Certification Issues

- Lack of required industry certifications

- Unwillingness to share quality reports

- No documented inspection processes

- High defect rates in sample parts

Equipment & Capability Limitations

- Using 3-axis machines for 5-axis part requirements

- Outdated equipment with poor maintenance

- Lack of specialized tooling for your materials

- Limited inspection equipment

Communication & Reliability Problems

- Inconsistent lead time commitments

- Delayed responses or poor communication

- Vague quotations without breakdowns

- No project management system

8. 2026 Industry-Specific CNC Manufacturer Standards Comparison

| Industry Sector | Key Certification | Tolerance Requirement | Material Expertise | Special Requirements |

|---|---|---|---|---|

| Aerospace | AS9100, NADCAP | ±0.001mm | Titanium, Inconel | Full traceability |

| Medical | ISO 13485 | ±0.002mm | PEEK, Ti-6Al-4V | Cleanroom Class 8 |

| Automotive | IATF 16949 | ±0.02mm | Aluminum, steel | High-volume production |

| Electronics | ISO 9001 | ±0.005mm | Copper, Kovar | Micro-machining |

* Standards for reference only, specific projects may have more stringent requirements

9. CNC Machining Processes & Technology Deep Dive

Advanced Machining Techniques

High-Speed Machining (HSM)

- Spindle speeds: 10,000-40,000 RPM for optimal material removal

- Feed rates: 5-15 m/min depending on material hardness

- Tool life extension: 30-50% compared to conventional machining

- Surface finish: Ra <0.4μm achievable with proper tooling

5-Axis Machining

- Continuous 5-axis simultaneous machining for complex geometries

- Reduced setup time: 40-60% fewer setups compared to 3-axis

- Improved accuracy: ±0.001mm positioning accuracy

- Tool reach: 360° access to part surfaces without reorientation

Micro-Machining

- Feature sizes: 0.1-1mm for electronic components and medical devices

- Tool diameters: 0.05-1mm with specialized holders

- Spindle speeds: 40,000-80,000 RPM for precise cutting

- Chip management: Critical for preventing tool breakage

Material-Specific Processing Parameters

Aluminum Alloys (6061/7075)

| Parameter | Value | Notes |

|---|---|---|

| Cutting Speed | 300-600 m/min | Higher for 6061 |

| Feed Rate | 0.1-0.3 mm/tooth | Depends on tool diameter |

| Depth of Cut | 1-5 mm | Roughing passes |

Stainless Steel (304/316)

| Parameter | Value | Notes |

|---|---|---|

| Cutting Speed | 100-300 m/min | Use coolant |

| Feed Rate | 0.05-0.2 mm/tooth | Lower for finishing |

| Depth of Cut | 0.5-3 mm | Avoid work hardening |

Carbon Fiber Composites (CFRP)

| Parameter | Value | Notes |

|---|---|---|

| Surface Speed | 550-760 m/min | Prevent delamination |

| Feed Rate | ~0.076 mm/tooth | Low force cutting |

| Tool Type | Diamond coated | Extended tool life |

* Processing parameters for reference only, actual values may vary by material grade and machine capabilities

Frequently Asked Questions (2026 Update)

Q1: What is the most important factor when choosing a CNC manufacturer?

A: While technical capabilities are crucial, we’ve found that communication effectiveness and quality management systems are the most reliable indicators of long-term success. Our 2025 data shows that manufacturers with proactive communication have 40% higher client retention rates.

Q2: How much should I expect to pay for CNC machining services in 2026?

A: Prices range from $50-$200 per hour depending on complexity, materials, and volume. For prototype parts (1-10 pieces), expect $100-$500 per part. For production runs (1,000+ pieces), costs typically drop to $10-$50 per part. Always request detailed cost breakdowns.

Q3: What certifications are absolutely necessary for medical device manufacturing?

A: ISO 13485 certification is mandatory for medical device manufacturing. Additionally, look for FDA registration and biocompatibility testing documentation. For implantable devices, ensure the manufacturer has experience with specialized cleaning and sterilization processes.

Q4: How can I verify a manufacturer’s capabilities before committing?

A: Request a sample part using your design, review their quality control documentation, and ask for client references in your industry. We recommend conducting a technical audit of their facilities and equipment. Goldcattle offers free manufacturer verification services for our clients.

Get Your Free CNC Manufacturer Evaluation

Choosing the right CNC manufacturer is too important to leave to chance. Let Goldcattle’s 15+ years of industry experience help you make an informed decision.

What You’ll Receive:

- Personalized manufacturer assessment based on your specific requirements

- Detailed comparison of 3-5 qualified CNC manufacturers

- Customized cost analysis and lead time projections

- Access to our exclusive CNC Manufacturer Evaluation Template

- Complimentary DFM review of your part designs