Step 1: Define Requirements & Material Selection

Key Considerations:

- Functional requirements: Load capacity (tensile strength ≥300MPa for structural parts), temperature resistance (-40℃ to 500℃), and environmental exposure (saltwater, chemicals). For example, a marine bolt requires 316L stainless steel (515MPa tensile strength, 1,500+ hours salt spray resistance) instead of carbon steel.

- Material properties: Match metals to application needs:

|

Metal Material

|

Tensile Strength

|

Corrosion Resistance

|

Primary Applications

|

|

Carbon Steel (1045)

|

620MPa

|

Low (rusts in moisture)

|

Structural brackets, machinery parts

|

|

Stainless Steel (304)

|

515MPa

|

High (1,000+ hours salt spray)

|

Food processing equipment, marine parts

|

|

Aluminum (6061-T6)

|

310MPa

|

Moderate (anodizable)

|

Automotive components, electronics

|

|

Titanium (Ti-6Al-4V)

|

895MPa

|

Excellent (resists seawater)

|

Aerospace parts, medical implants

|

- Cost vs. performance: Balance material expense with longevity. For example, 304 stainless steel costs 3x more than carbon steel but lasts 10x longer in wet environments.

Step 2: Design & Engineering (DFM)

Critical Design Elements:

- Tolerance definition: Specify achievable tolerances based on manufacturing method (e.g., ±0.005mm for CNC machining, ±0.1mm for casting). A precision gear requires ±0.01mm tooth spacing, while a bracket may tolerate ±0.5mm.

- Feature optimization:

-

- Avoid sharp internal corners (use 0.5mm radii) to prevent stress concentration in CNC-machined parts.

-

- Design uniform wall thickness (≥2mm for cast parts) to prevent cooling defects in aluminum casting.

-

- Include draft angles (1-3°) in injection-molded metal parts for easy removal from molds.

- FEA simulation: Test virtual prototypes for stress, vibration, and thermal performance. A 4140 steel axle designed with FEA showed a 20% weight reduction by optimizing rib thickness without compromising strength.

Step 3: Choose Manufacturing Process

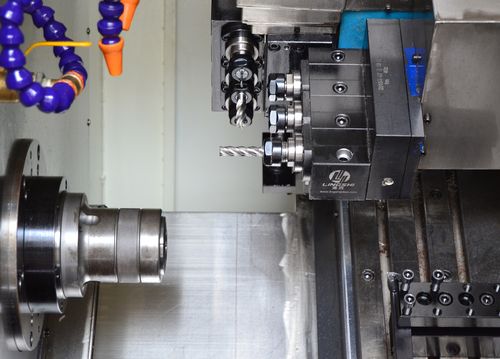

1. CNC Machining (Best for Precision, Low-Medium Volume)

- Process: Removes material from solid blocks using 3-5 axis CNC mills/turning centers, achieving ±0.005mm tolerance.

- Applications: Complex parts with tight tolerances (e.g., aerospace fittings, medical instruments). A 6061 aluminum valve body with 12 precision holes (0.003mm positional accuracy) is machined in 2 hours per part.

- Advantages: High precision, Suitable for a variety of materials,no tooling costs for small batches (1-100 units).

2. Forging (Best for High-Strength, Medium-High Volume)

- Process: Compresses heated metal (700-1,200℃) into dies to shape parts, aligning grain structure for 30% higher strength than machining.

- Applications: Crankshafts, gears, and structural parts. A 4340 steel forging for a truck axle withstands 100,000+ load cycles without fatigue failure.

- Advantages: Superior strength, Suitable for mass production (1,000+ units), cost-effective for large parts.

3. Casting (Best for Complex Shapes, High Volume)

- Process: Pours molten metal into molds (sand, die, or investment casting) to create intricate shapes. Aluminum die casting produces parts with ±0.1mm tolerance at 100+ units/hour.

- Applications: Engine blocks, pump housings. A 316L stainless steel investment casting for a valve body includes internal channels impossible to machine cost-effectively.

- Advantages: Complex geometry capability, low per-unit cost for high volumes (10,000+ units).

4. Welding & Assembly (Best for Large/Composite Parts)

- Process: Joins metal components using MIG/TIG welding (steel/aluminum) or laser welding (titanium), ensuring 99% weld penetration and tensile strength ≥80% of base metal.

- Applications: Truck frames, industrial machinery. A 6m steel frame welded with robotic MIG welders achieves 0.5mm straightness over its length, critical for alignment.

- Advantages: Enables large/hybrid parts, reduces material waste vs. solid machining.

Step 4: Prototyping & Testing

Prototype Methods:

- CNC machined prototypes: Produce 1-10 functional parts in 3-5 days for fit testing. A stainless steel bracket prototype undergoes load testing (10,000 cycles at 500N) to verify strength.

- 3D printed metal prototypes: Uses SLM (Selective Laser Melting) to create titanium or stainless steel parts with 0.1mm layer resolution, ideal for complex geometries (e.g., lattice structures).

- Validation tests:

-

- Dimensional inspection (CMM for ±0.001mm accuracy).

-

- Material testing (tensile, hardness, corrosion resistance).

-

- Functional testing (e.g., pressure testing for fluid-carrying parts at 150% of rated pressure).

Step 5: Production & Quality Control

Production Technologies:

- Automated CNC machining: 5-axis CNC centers with robotic loading produce 500+ parts/day with ±0.005mm tolerance. In-process probing corrects tool wear (≤0.002mm) for uninterrupted accuracy.

- Die casting automation: High-pressure die casting machines (4,000 tons clamping force) produce 1,000+ aluminum parts/day, with X-ray inspection to detect internal defects (≥0.5mm voids).

- Welding robotics: 6-axis robots perform MIG welding with 0.1mm torch positioning accuracy, ensuring consistent bead geometry (3-5mm width) across 10,000+ welds.

Quality Assurance:

- Statistical Process Control (SPC): Monitors critical dimensions (e.g., diameter, thickness) with CPK ≥1.33, ensuring 99.97% of parts meet specifications.

- Non-destructive testing (NDT): Ultrasonic testing detects subsurface defects in forged parts; dye penetrant testing identifies surface cracks in welded joints.

- Final inspection: 100% visual inspection for surface finish (Ra ≤0.8μm for critical areas) and functional testing (e.g., torque testing for bolts to 120% of rated torque).

Step 6: Finishing & Surface Treatment

- Painting & powder coating: Applies 60-100μm layers (epoxy/polyester) for corrosion resistance (1,000+ hours salt spray) and color customization (ΔE <1).

- Plating: Chrome plating (0.05mm thickness) for decorative parts; zinc plating for bolts (1,000+ hours corrosion resistance).

- Anodizing: Creates 5-25μm oxide layers on aluminum (6061-T6) for wear resistance (300HV hardness) and dye acceptance (custom colors).

- Heat treatment: Hardens steel parts (e.g., 4140 steel quenched to 50-55 HRC) for wear resistance; anneals aluminum to reduce brittleness.

Common Challenges & Solutions in Metal Part Production

- Warpage in thin parts: Use stress-relief annealing (600℃ for steel) and fixture-based machining to reduce distortion by 80%.

- Corrosion in high-moisture environments: Select 316L stainless steel or apply duplex coatings (zinc + epoxy) for 2,000+ hours salt spray resistance.

- Tolerance stack-up in assemblies: Design with GD&T (Geometric Dimensioning and Tolerancing) to control cumulative variation, ensuring ≤0.1mm total assembly gap.

Why Partner with Goldcattle for Metal Part Production?

- Material-optimized processes (e.g., CNC machining for precision, forging for strength).

- Strict quality control (ISO 9001, IATF 16949) with 99.95% part acceptance rate.

- Scalable production (1-100,000+ units) with lead times as short as 3 days for prototypes.